Porous carbon composite material containing cobalt and nickel and preparation method of porous carbon composite material containing cobalt and nickel

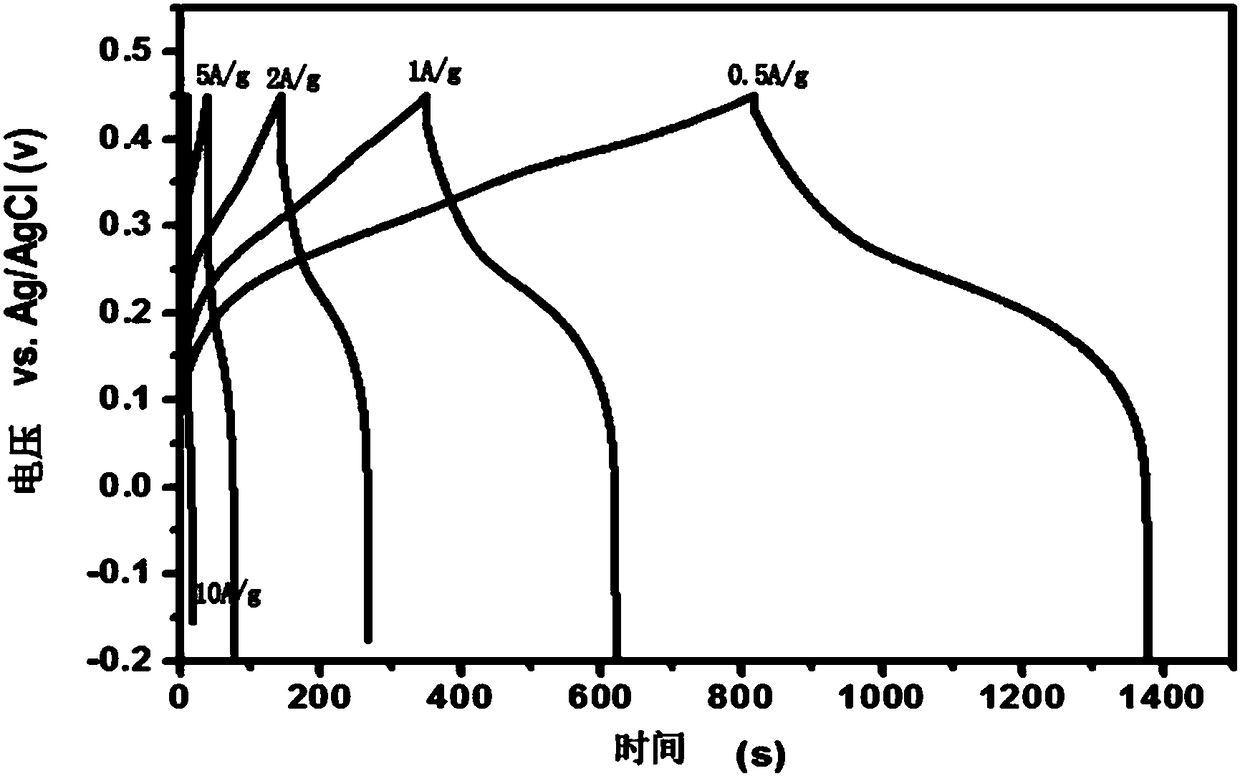

A composite material and porous carbon technology, which is applied in the field of inorganic nanomaterials and electrochemistry, can solve the problems of high energy consumption and low catalytic activity, and achieve the effect of proper pore size distribution, high specific surface area, and improved electric double layer capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a cobalt-nickel porous carbon composite material, comprising the steps of: first mixing cobalt chloride hexahydrate, nickel chloride hexahydrate and polyvinylpyrrolidone in a ratio of 1:1:1 (mass ratio), stirring for 7 hours, Then vacuum distillation quickly removed most of the moisture, and then placed in a vacuum oven for drying. Under the protection of nitrogen atmosphere, carbonize at 800°C for 2 hours. After natural cooling, the pH was washed with deionized water to neutral, and dried to obtain a cobalt-nickel porous carbon composite material. The nitrogen adsorption and desorption performance of the carbon material was tested with a Beste 3H-2000PM2 high-performance specific surface and micropore analyzer, and the specific surface area of the carbon material was 203m 2 / g. Through the XPS test, cobalt and nickel elements were successfully doped into the material, and the mass contents of cobalt and nickel in the material were 2.3% and 3...

Embodiment 2

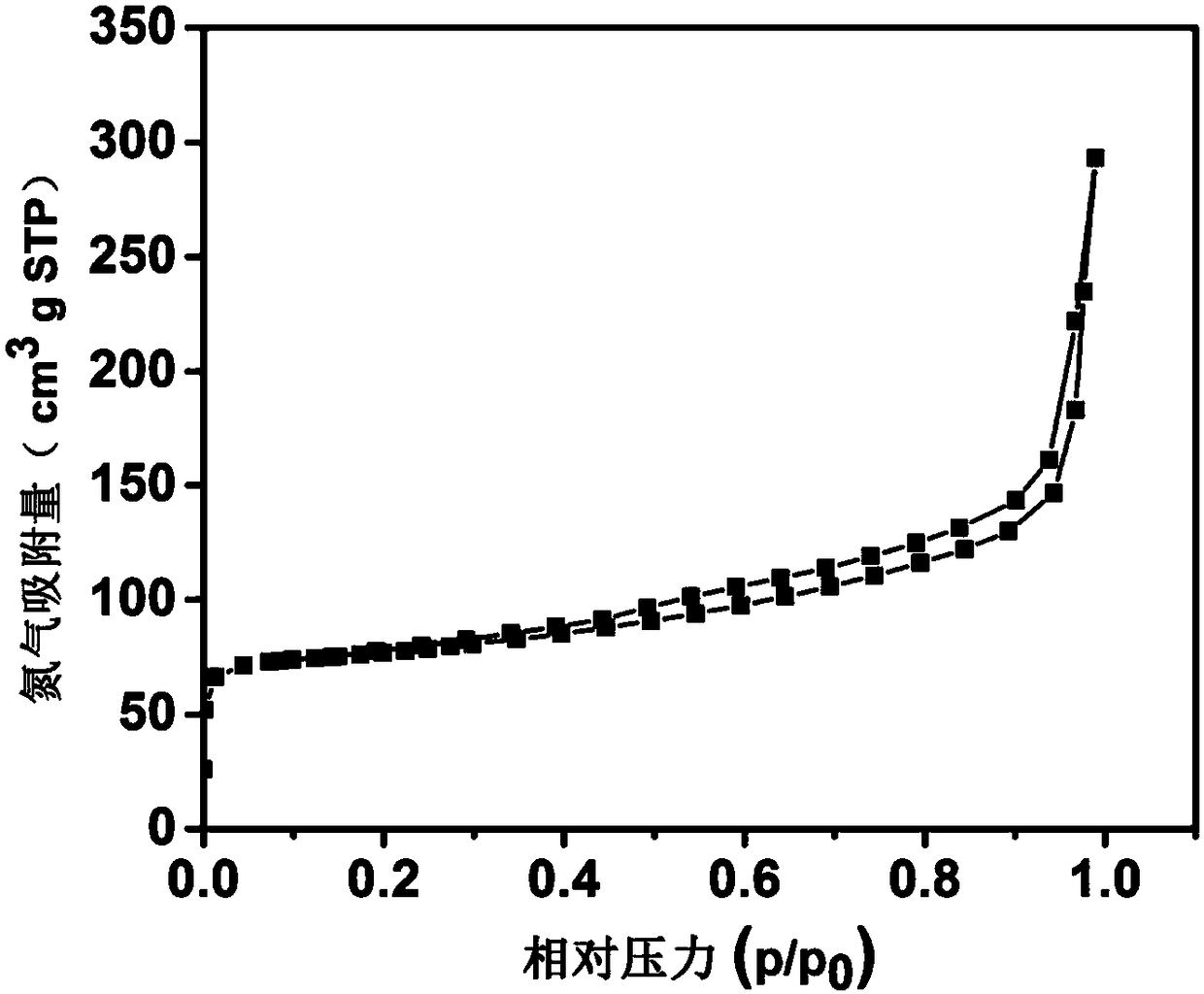

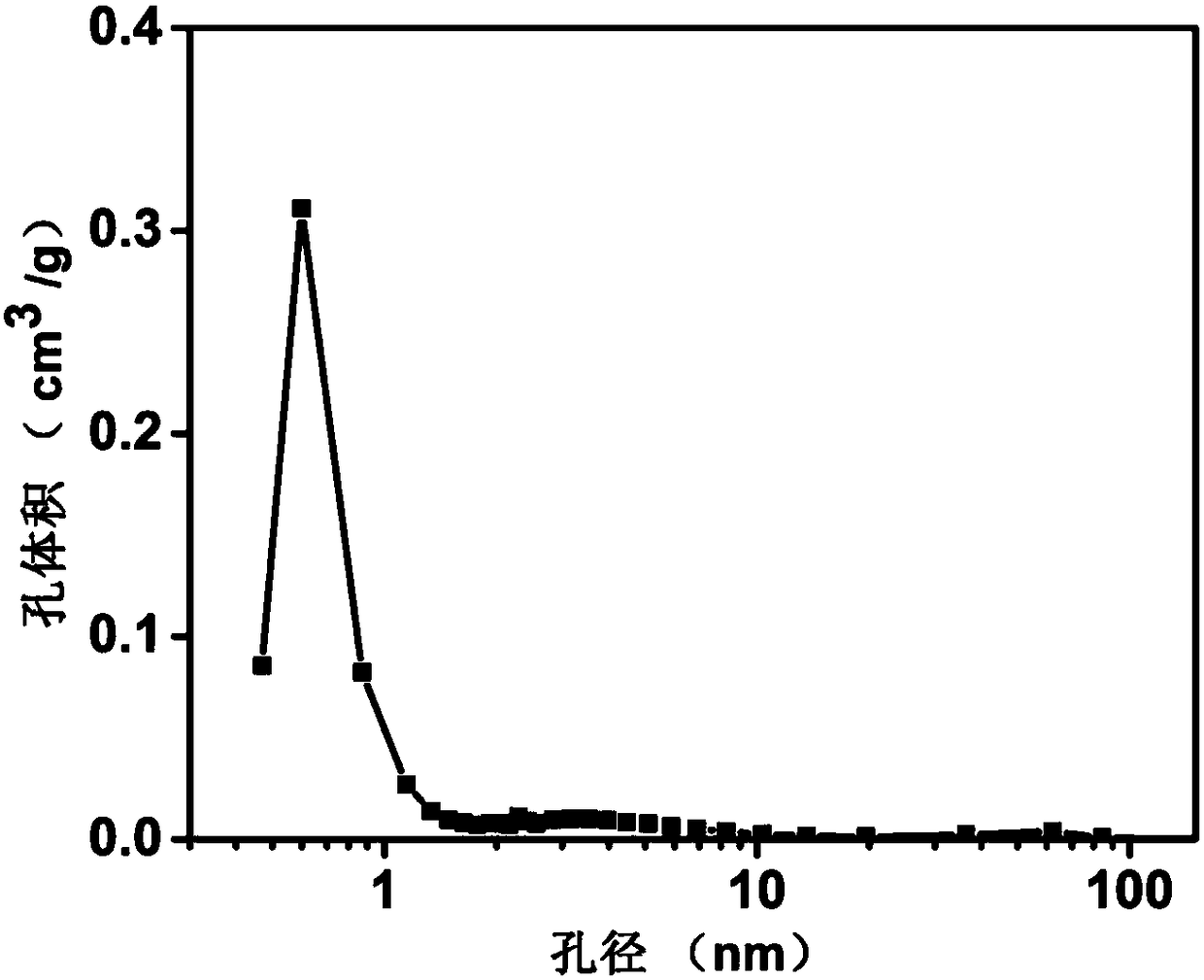

[0027] A preparation method of a cobalt-nickel porous carbon composite material, comprising the steps of: first mixing cobalt chloride hexahydrate, nickel chloride hexahydrate and polyvinylpyrrolidone in a ratio of 1:1:2 (mass ratio), stirring for 8 hours, Then vacuum distillation quickly removed most of the moisture, and then placed in a vacuum oven for drying. Under the protection of nitrogen atmosphere, carbonize at 800°C for 2 hours. After natural cooling, the pH was washed with deionized water to neutral, and dried to obtain a cobalt-nickel porous carbon composite material. The carbon material has a specific surface area of 243.7m 2 / g. The mass contents of cobalt and nickel in the material are 3.2% and 3.8% respectively. figure 1 is the nitrogen adsorption-desorption curve of the nitrogen-containing microporous carbon material obtained in Example 2.

Embodiment 3

[0029] A preparation method of a cobalt-nickel porous carbon composite material, comprising the steps of: first mixing cobalt chloride hexahydrate, nickel chloride hexahydrate and polyvinylpyrrolidone in a ratio of 1:1:3 (mass ratio), stirring for 6 hours, Then vacuum distillation quickly removed most of the moisture, and then placed in a vacuum oven for drying. Under the protection of nitrogen atmosphere, carbonize at 800°C for 2 hours. After natural cooling, the pH was washed with deionized water to neutral, and dried to obtain a cobalt-nickel porous carbon composite material. The carbon material has a specific surface area of 221m 2 / g. The mass contents of cobalt and nickel in the material are 3.9% and 4.1% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com