A kind of preparation method of white light led healthy light source

A healthy and white light technology, applied in the field of white LED healthy light source preparation, can solve problems such as increasing the complexity of problems, inability to accurately express the color rendering performance of LED light sources, no spectrum and light quality optimization, etc., to achieve soft light and uniform light emission , the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

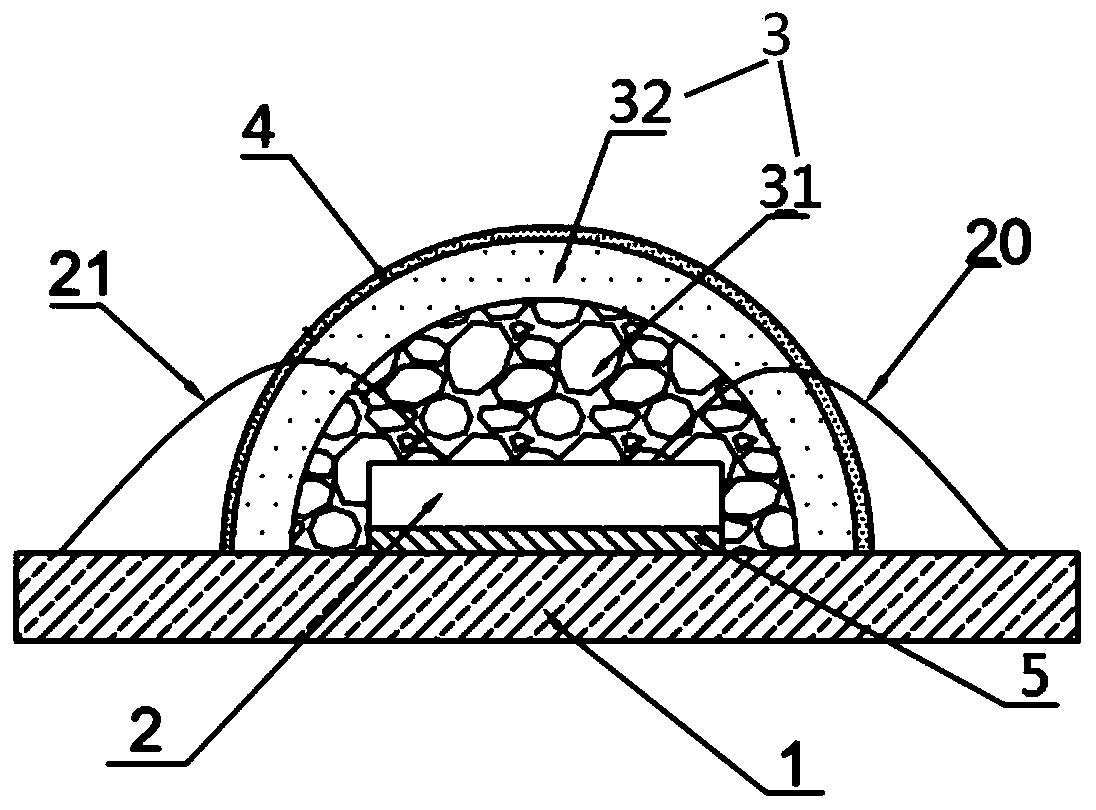

[0033] refer to figure 1 , the 420nm blue light chip 2 is fixed on the SMD bracket 1 containing the circuit layer through the crystal bonding glue 5, after the crystal bonding automation equipment completes the crystal bonding operation, it is put into the oven equipment for baking and curing; after the curing is completed and passed the inspection, pass The automatic wire bonding equipment welds the positive electrode 20 gold wire of the Blu-ray chip 2 on the positive electrode of the circuit layer, and welds the negative electrode 21 gold wire on the negative electrode of the circuit layer.

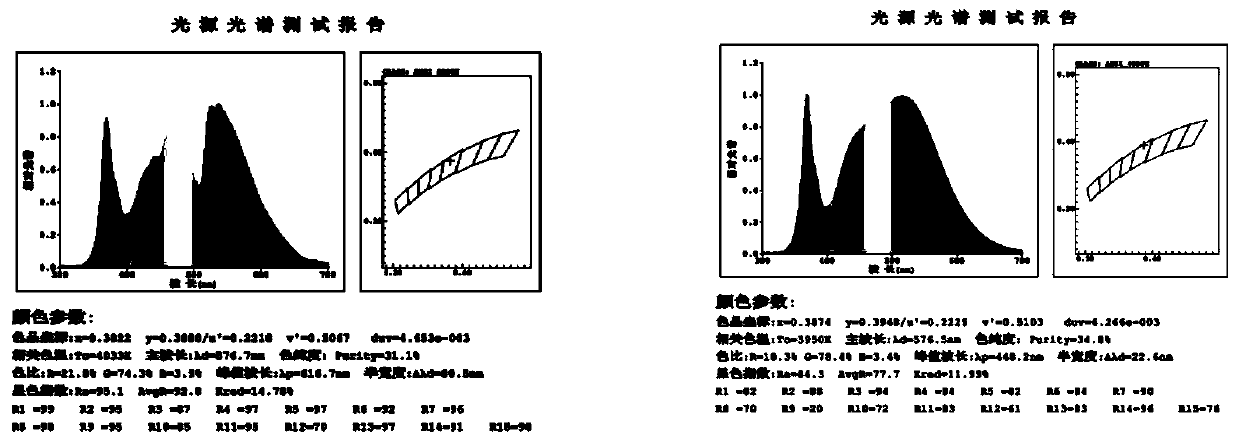

[0034] After the wire bonding is completed, green powder LuAG: Ce, red powder (Ca, Sr, Ba) AlSiN 3 : Eu is mixed with silica gel according to the effect ratio of color temperature 4000K to form the first slurry with a total phosphor content of 40wt%, which is coated on the Blu-ray chip 2 by dispensing with a coating thickness of 0.25mm, and then left at room temperature 3h, after the p...

Embodiment 2

[0042] Fix the 465nm blue-ray chip on the COB bracket containing the circuit layer through the die-bonding glue. After the die-bonding automation equipment completes the die-bonding operation, put it into the oven equipment for baking and curing; after the curing is completed and passed the inspection, pass the automatic wire bonding equipment Weld the positive gold wire of the Blu-ray chip to the positive pole of the circuit layer, and solder the negative gold wire to the negative pole of the circuit layer.

[0043] After the wire welding is completed, put the green powder Ba 1-x-y Sr x Ca y Si 2 o 4 : Eu(0≤x≤1, 0≤y≤1)), red powder Ba 2- x Sr x Si 5 N 8 :Eu, (Ca,Sr,Ba)AlSiN 3 : Eu is mixed with epoxy resin according to the effect ratio of color temperature 4000K to form the first slurry with a total phosphor content of 40wt%, which is coated on the blue-ray chip by dispensing with a coating thickness of 0.25mm, and then statically placed at room temperature Set asid...

Embodiment 3

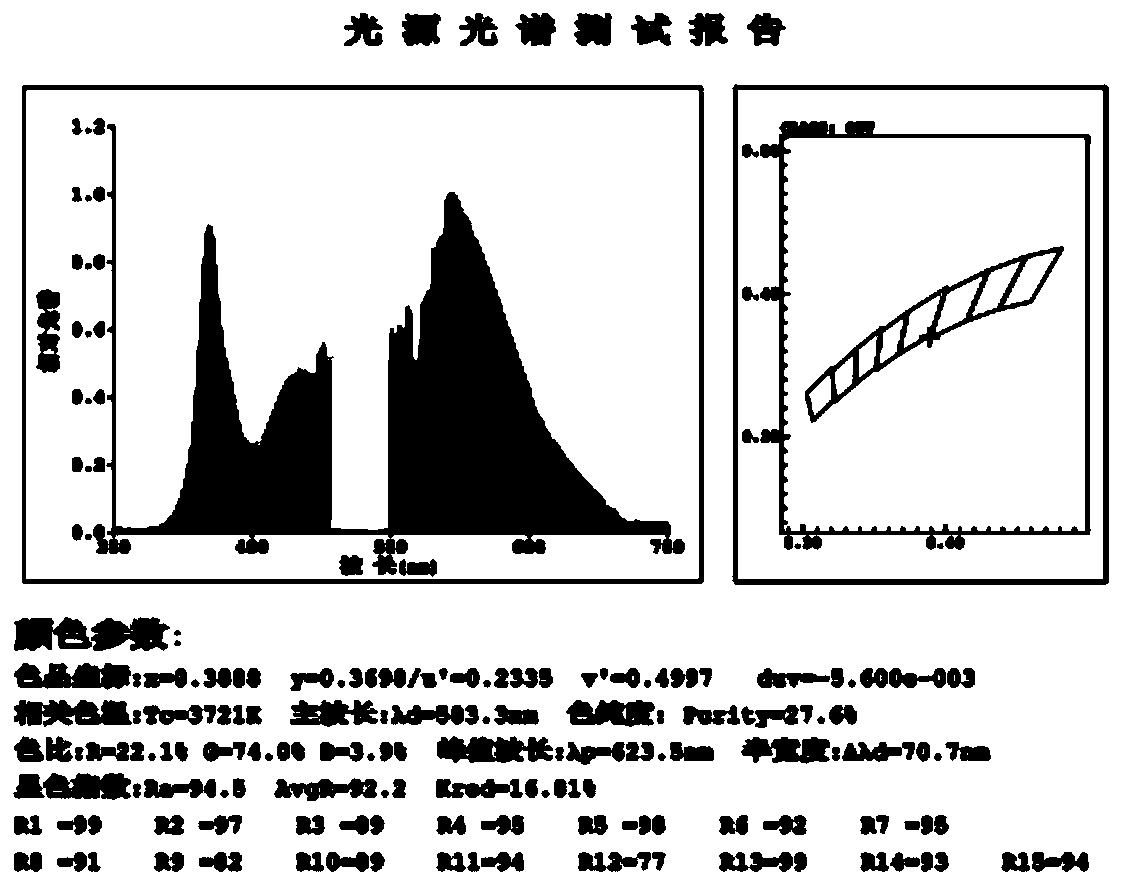

[0048] refer to Figure 4 , the 450nm Blu-ray chip 2 is fixed on the SMD bracket 1 containing the circuit layer through the die-bonding glue. The wire bonding equipment welds the gold wire of the positive electrode 20 of the blue light chip 2 on the positive electrode of the circuit layer, and welds the gold wire of the negative electrode 21 on the negative electrode of the circuit layer.

[0049] After the wire bonding is completed, the green powder Ga / Ge-LuAG: Eu, the red powder Ba 2-x Sr x Si 5 N 8 :Eu is mixed with silica gel according to the effect ratio of color temperature 4000K, and then NdF with a particle size of about 0.3 μm is added 3 Mix evenly to form a phosphor with a total content of 35wt%, NdF 3 A third slurry with a content of 4wt%, coated on the Blu-ray chip 2 by dispensing, with a coating thickness of 0.45 mm, standing at room temperature for 1-2 hours, and then baking and curing at 70°C A composite encapsulation layer 3' is formed.

[0050] Move the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com