Scr denitrification catalyst and preparation method thereof

A technology of denitration catalyst and dilute nitric acid, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to improve mechanical service life, improve wear resistance, improve sulfur resistance and alkali metal resistance The effect of the poison ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the denitrification catalyst is to use the above solid solution as the matrix material, the above matrix material contains the active material vanadium pentoxide, and at the same time add glass fiber, wood pulp, binder, wollastonite, deionized water and ammonia water, etc. to mix and filter , extrusion, drying and roasting.

[0047] In the above technical solution, according to the mass ratio, matrix material: glass fiber: wood pulp: binder: wollastonite: deionized water: ammonia water = 50~65:5~8:1~5:0.5~2:1 ~3: 20~30: 5~10.

[0048] In the above technical scheme, the speed of mixing is 300~500r / min, the time is 5~8h; the pressure of filtration is 3~5MPa, the pressure of extrusion is 4~6MPa, the drying condition is 40~60℃, and the drying time is 192 ~264h, the calcination temperature is 550~620℃, and the calcination time is 30~35h.

[0049] This technical solution can better solve the dust treatment produced by the furnace of the glass facto...

Embodiment 1

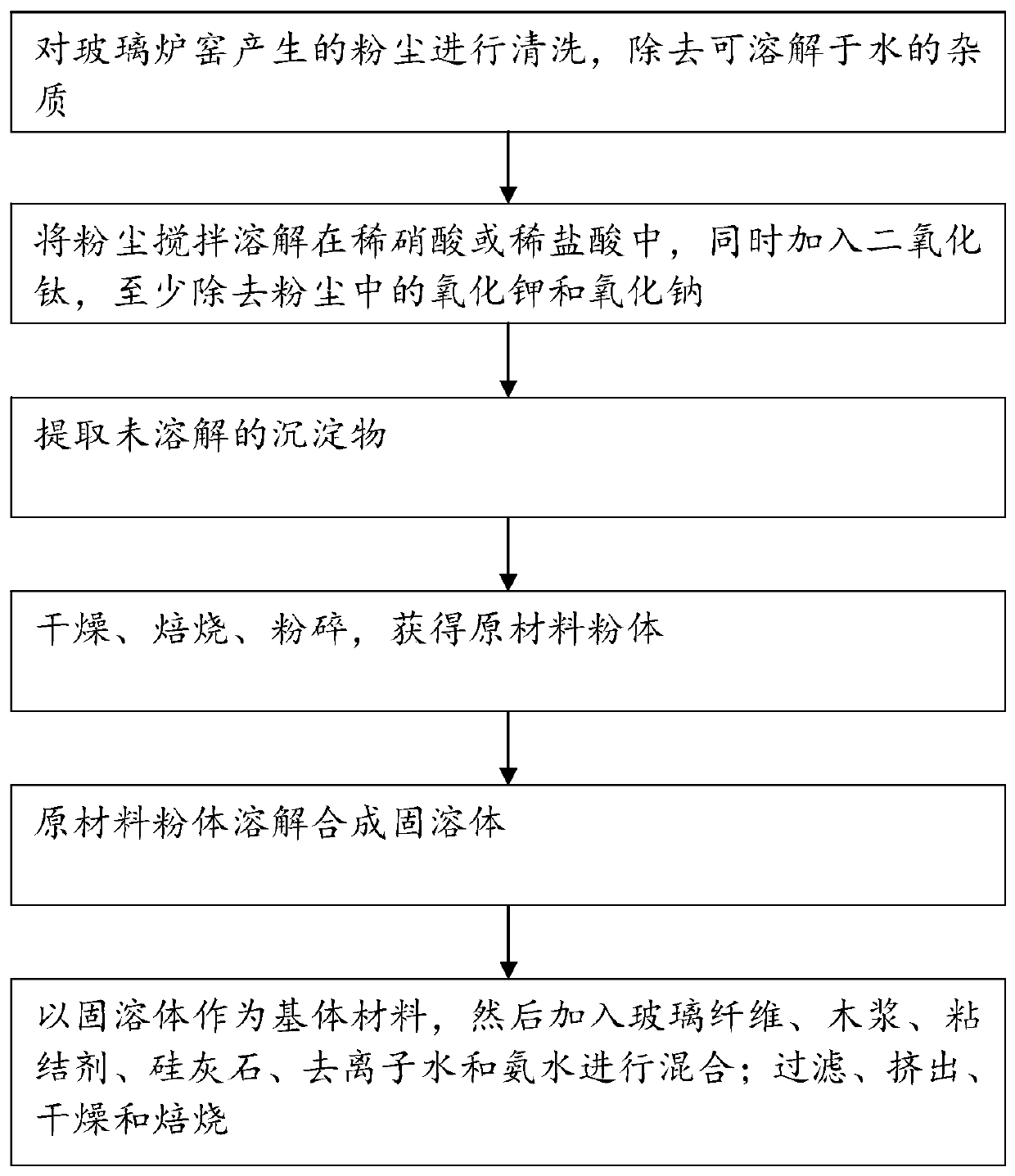

[0052] The preparation method of SCR denitration catalyst comprises:

[0053] (1) Use deionized water to remove water-soluble impurities in the dust generated by glass furnaces;

[0054] (2) Under the condition of stirring, use dilute nitric acid to dissolve the dust, the stirring speed is 30r / min, and the cleaning time is 4h, at least the potassium oxide and sodium oxide substances in the dust are cleaned, and the mass ratio of 88% is added during the stirring process Titanium dioxide;

[0055](3) Extract the undissolved precipitate, and use a filter bag with a pore size of 0.3 μm to filter, collect and purify;

[0056] (4) Dry at 120°C for 8 hours;

[0057] (5) Roasting at 450°C for 4 hours;

[0058] (6) Crushing, the average particle size of the product is 2 μm;

[0059] (7) The raw material powder is dissolved to form a solid solution;

[0060] (8) Use solid solution as the matrix material, and then add glass fiber, wood pulp, binder, wollastonite, deionized water and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com