Method for calculating drawing force in aluminum alloy plate preparation process and application thereof

A technology of aluminum alloy plate and preparation process, applied in calculation, computer-aided design, special data processing application, etc., can solve problems such as difficult control of performance, complex production process, poor corrosion of alloy, etc., shorten production cycle and improve dimensional accuracy , to ensure the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

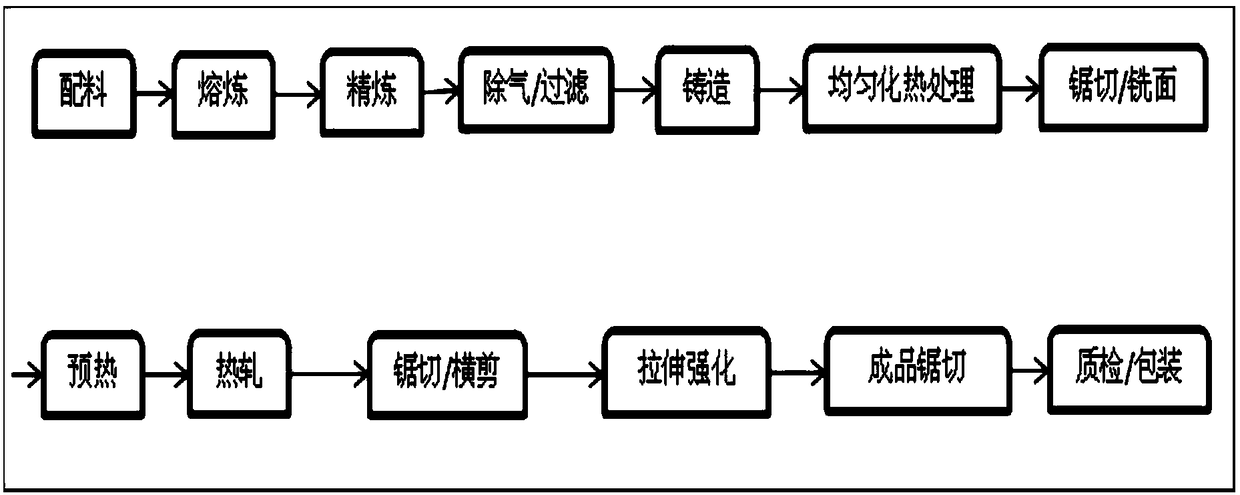

[0041] An application of the above-mentioned calculation method in the production of high-magnesium aluminum alloy plates, the operation steps are as follows:

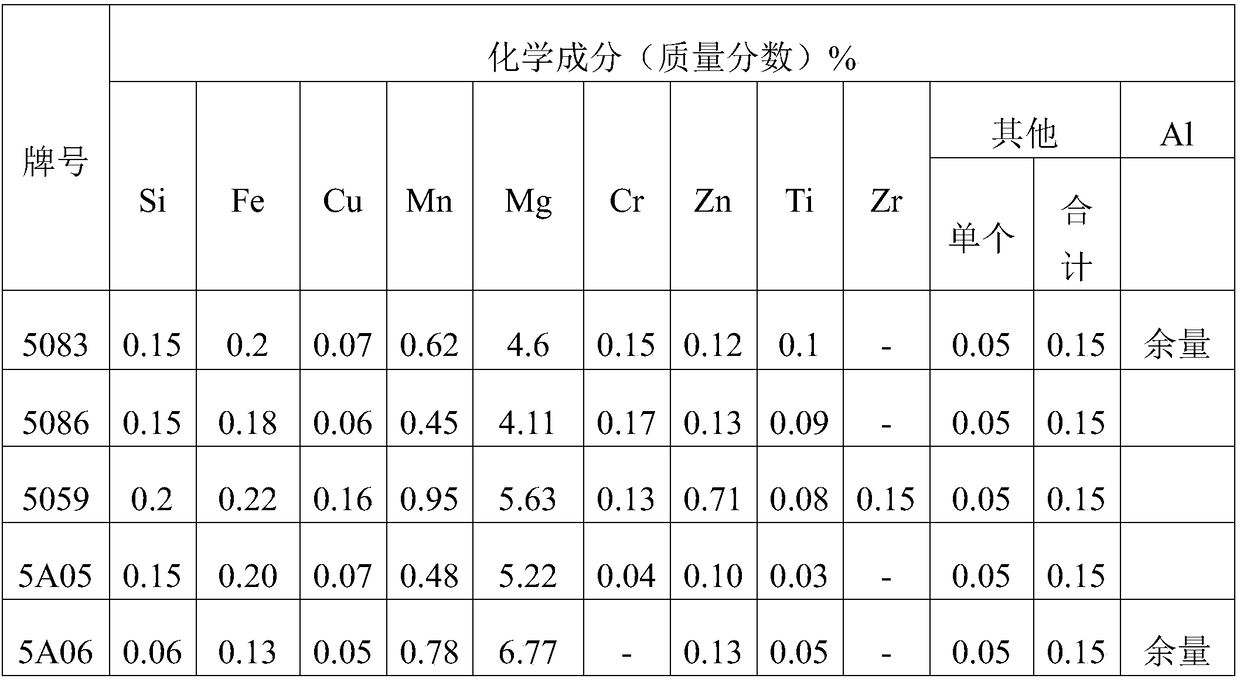

[0042] (1) Take the raw material of 5083 high-magnesium aluminum alloy, the composition of which is shown in the "5083" column of Table 1, and carry out smelting, refining and casting in sequence; among them, the melting temperature is 720-750°C, smelting for 6 hours, and the refining temperature is 730-740°C , keep warm for 8h; perform multi-stage degassing treatment on the aluminum alloy melt, significantly reduce the gas content in the aluminum melt, in order to reduce casting defects such as pores and looseness in the aluminum alloy flat ingot, select a 30ppi filter plate to remove the aluminum melt oxides, non-metallic inclusions and other harmful metal impurities in the body to reduce casting defects such as slag inclusions in the ingot. After removing impurities and degassing, semi-continuous casting is used to p...

Embodiment 2

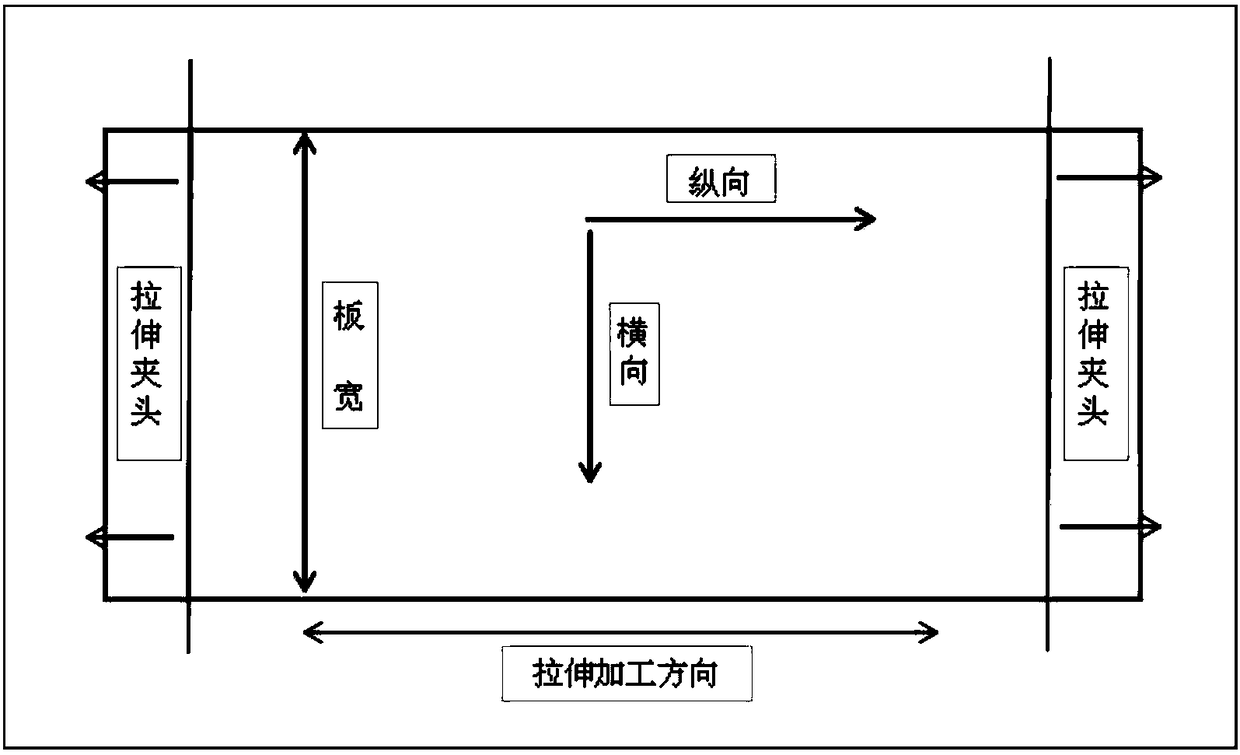

[0047] (4) After the plate obtained in step (3) is naturally cooled, trim the edge to 500mm, take a sample to detect the transverse performance, see Table 2 No. C, and then stretch it, and set the target expectation as transverse yield R=255MPa ( 5083-H24 / H34 yield strength 250MPa), Kr=Kx=1.18, tensile force required for stretching F=D×W×R×Kr=100mm×500mm×255MPa×1.18=15.05MN; tensile rate is 4.0mm / s, the high-magnesium aluminum alloy plate is obtained, and samples are taken to detect the mechanical properties and corrosion properties. The properties are shown in Table 2, No. D.

[0048] All the other operations are identical to Example 1.

Embodiment 3

[0050] An application of the above-mentioned calculation method in the production of high-magnesium aluminum alloy plates, the operation steps are as follows:

[0051] (1) Take the raw material of 5086 high-magnesium aluminum alloy, the composition of which is shown in the "5086" column of Table 1, and carry out smelting, refining and casting in sequence; among them, the melting temperature is 750-780°C, smelting for 4 hours, and the refining temperature is 710-730°C , keep warm for 2 hours; carry out multi-stage degassing treatment on the aluminum alloy melt, significantly reduce the gas content in the aluminum melt, in order to reduce casting defects such as pores and looseness in the aluminum alloy slab, select a 40ppi filter plate to remove the aluminum melt oxides, non-metallic inclusions and other harmful metal impurities in the body to reduce casting defects such as slag inclusions in the ingot. After removing impurities and degassing, semi-continuous casting is used to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com