A multi-component composite toughened bionic structural armor and its preparation method

A multi-component compounding and toughening technology, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of high density and low armor protection ability of light weight, and achieve the solution of compounding of heterogeneous materials, Ensure rationality and scientificity, improve the effect of protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

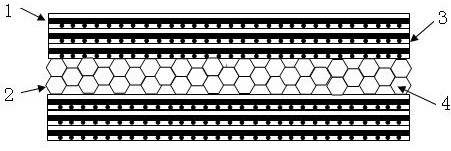

Image

Examples

Embodiment 1

[0033] Test materials: high-purity titanium foil thickness 30um, high-purity titanium foil thickness 100um, high-purity aluminum foil thickness 30um, SiC fiber, titanium alloy honeycomb, energy-absorbing and shock-absorbing high-elastic resin-based composite material; armor length and width are 100mm, The thickness is 30mm.

[0034] The specific implementation steps are as follows:

[0035] Step 1. First, surface-treat the high-purity titanium foil and aluminum foil, clean them, and then cut the titanium foil and aluminum foil into 100mm×100mm squares;

[0036] Step 2: Cut the SiC fiber into 100mm×100mm cubes after being wound by an automatic winding machine; a layer of transition metal can be deposited on the surface of the reinforcing fiber by means of magnetron sputtering, and then the fiber is wound by a fiber winding machine.

[0037] Step 3. Stack titanium foil (30um), aluminum foil (30um), titanium foil (100um), SiC fiber, titanium foil (100um) and aluminum foil (30um)...

Embodiment 2

[0043] Test materials: high-purity titanium foil thickness 50um, high-purity titanium foil thickness 100um, high-purity aluminum foil thickness 50um, SiC fiber, titanium alloy honeycomb, energy-absorbing and shock-absorbing resin-based composite materials; armor length and width are 100mm, and thickness is 30mm. The thickness of the high-purity titanium foil and aluminum foil used in step 1 was changed to 50um, and the remaining specific implementation steps were the same as in Example 1.

Embodiment 3

[0045] The thickness of high-purity titanium foil is 100um, the thickness of high-purity titanium foil is 100um, the thickness of high-purity aluminum foil is 70um, SiC fiber, titanium alloy honeycomb, energy-absorbing and shock-absorbing resin-based composite materials; the length and width of the armor are 100mm, and the thickness is 30mm. The high-purity titanium foil used in step 1 was changed to 100um and the thickness of the aluminum foil was changed to 70um, and the rest of the specific implementation steps were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com