A method for crushing an oxide film on the surface of an aluminum alloy

A technology of aluminum alloy surface and crushing method, applied in metal processing equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problem of hindering the mutual diffusion of aluminum atoms, unable to form a diffusion bonding interface, and the diffusion bonding technology has not been well solved, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only used to explain the present invention, not to limit the present invention.

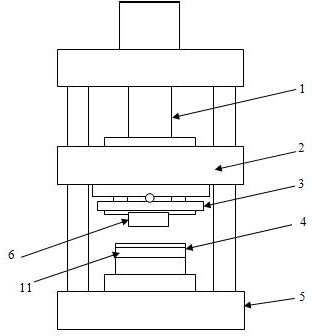

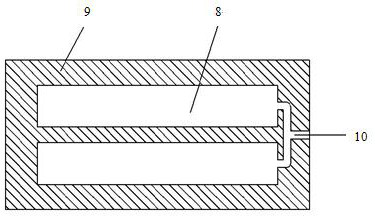

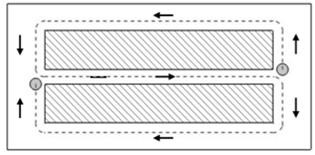

[0026] The technical solution is to use a pulsed strong magnetic field to crush an oxide film in a local selective area on the surface of an aluminum alloy plate. Such as figure 1 , figure 2 , image 3 As shown, the relevant equipment may include a hydraulic press, a magnetic pulse power supply, a magnet moving device, a magnet 6, an electric heating power supply, and the like. The magnet 6 can be a solenoid coil or a uniform pressure coil, and is installed on the magnet moving device. The magnet moving device can be a two-dimensional mobile platform 3 controlled by a numerical control system. The magnet moving device is installed on the upper platform 2 of the hydraulic press, and the upper platform 2 Driven by the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com