Diffusion welding connection method of dissimilar metal honeycomb panel structure realized by laser

A technology of dissimilar metals and connection methods, which is applied in laser welding equipment, metal processing, welding equipment, etc., can solve the problems of poor joint performance, complicated process, and low efficiency, and achieve stable welding process, improved production efficiency, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Honeycomb panel structure welding, T-joint.

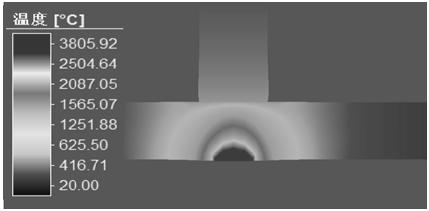

[0039] see figure 1 As shown in Fig. 1, the aluminum alloy / titanium alloy dissimilar metal fillet joint model is established, and the temperature field of the welded joint is numerically calculated before welding to obtain the temperature distribution in the joint, and the laser irradiation position is determined as figure 1 As shown, the laser power is 4-6kw, and the welding speed is 140-220mm / min.

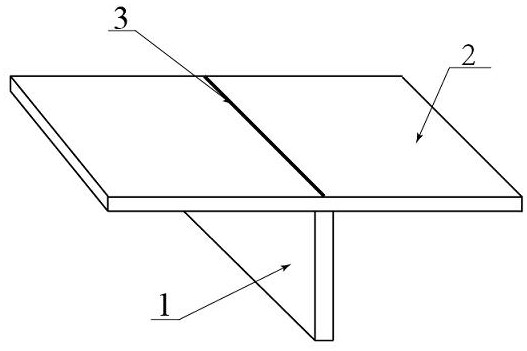

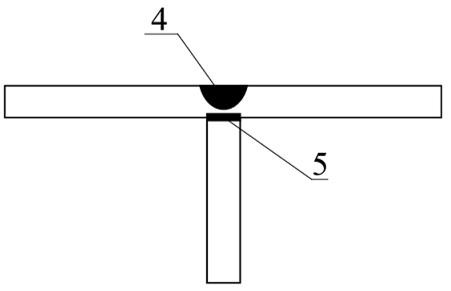

[0040] see figure 2 and image 3 As shown, the aluminum alloy / titanium alloy dissimilar metal T-joint is welded by the method of the present invention, the aluminum alloy plate 1 and the titanium alloy plate 2 are fixed on the fixture, the laser beam is welded along the welding track 3, and the laser beam is irradiated on the outer plate The titanium alloy plate 2 is heated to melt part of the metal 4, and the honeycomb support plate is heated by heat conduction to form a diffusion weld with the outer plate to obtain a diffus...

Embodiment 2

[0043] Welding and butt joints of large structural parts.

[0044] see Figure 4 As shown, a stainless steel / titanium alloy dissimilar metal butt joint model is established, the joint temperature field is numerically calculated, the temperature distribution in the joint is obtained, and the process parameters are determined: the laser power is 2-5kw, and the welding speed is 160-200mm / min.

[0045] see Figure 5 and Figure 6 As shown, adopt the method of the present invention to weld stainless steel / titanium alloy dissimilar metals, fix the titanium alloy plate 2 and the stainless steel plate 6 on the fixture, weld the laser beam along the welding track 3, and direct the laser spot to the titanium alloy plate side Offset, 0.6-4mm away from the surface to be welded, melt part of the metal 4 on the titanium alloy base material, increase the temperature of the contact surface through the heat conducted from the side of the titanium alloy plate, produce a diffusion reaction, fo...

Embodiment 3

[0048] Welding of large structural parts, 45° inclined butt joints.

[0049] see Figure 7 As shown, a stainless steel / titanium alloy dissimilar metal butt joint model is established, and the joint surface to be welded is processed into a 45° inclined plane to increase the contact area, thereby increasing the diffusion connection area. At the same time, the laser irradiation angle must be the same as that of the inclined plane, parallel to the inclined plane, numerically calculate the temperature field of the joint, obtain the temperature distribution in the joint, and determine the process parameters. The laser power is 3-6kw, and the welding speed is 160-220mm / min. .

[0050] see Figure 8 and Figure 9 As shown, adopt the method of the present invention to carry out the welding of stainless steel / titanium alloy dissimilar metals, fix the titanium alloy plate 2 and the stainless steel plate 6 on the fixture, weld the laser beam along the welding track 3, and direct the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com