Laminate and method for manufacturing laminate

A technology of laminates and printed layers, applied in chemical instruments and methods, lamination, coating, etc., can solve problems such as inability to obtain gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0287] Hereinafter, in order to facilitate the understanding of the present invention, the present invention will be specifically described through examples, but the present invention is not limited to the examples. In addition, the parts and % in each example are based on a mass basis unless otherwise indicated.

[0288]

[0289]In a four-necked flask equipped with a stirrer, a thermometer, a reflux cooling tube, and a nitrogen gas introduction tube, the number average molecular weight obtained by reacting a mixture of ethylene glycol and neopentyl glycol (molar ratio=1 / 1) with adipic acid was 1,800 605.9 parts of polyester diol and 94.1 parts of isophorone diisocyanate were reacted at 90° C. for 10 hours under a nitrogen stream to produce a prepolymer with a free isocyanate value of 1.02% by mass, and ethyl acetate was added thereto 300 parts of ester to make a homogeneous solution of urethane prepolymer. Next, to a mixture containing 18.1 parts of isophorone diamine, 873...

manufacture example 1

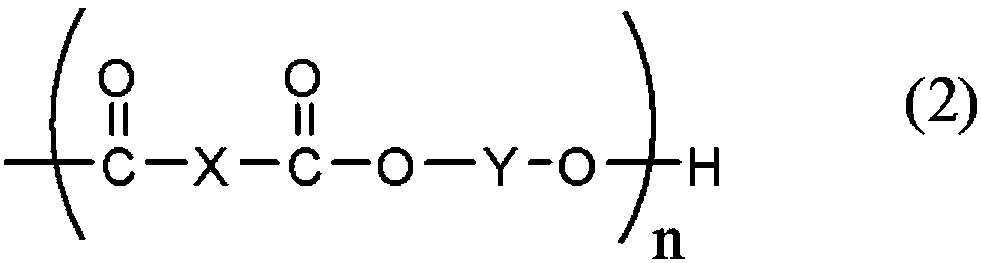

[0291] (Manufacturing example 1) Manufacture of polyester polyol "EGoPA900" with a number average molecular weight of 900 consisting of ethylene glycol and phthalic acid

[0292] In the polyester reaction container equipped with stirrer, nitrogen inlet pipe, Snyder (Snyder) tube, condenser, drop into ethylene glycol 747.31 parts, phthalic anhydride 1252.70 parts and titanium tetraisopropoxide 0.02 parts, with fine Slowly heat the upper part of the distillation tube so that the temperature does not exceed 100°C, and keep the internal temperature at 220°C. When the acid value reached below 4 mgKOH / g, the esterification reaction was terminated to obtain a polyester polyol "EGoPA900" with a number average molecular weight of 900. The number of repeating units of this polyester polyol was n=3.94, and the value of the permeability factor of residues other than terminal hydroxyl groups was 54.8. The hydroxyl value is 120.9.

manufacture example 2

[0293] (Manufacture example 2) Manufacture of polyester polyol "EGoPA1100" with a number average molecular weight of 1100, which consists of ethylene glycol and phthalic acid

[0294] Add 747.31 parts of ethylene glycol, 1252.70 parts of phthalic anhydride and 0.02 part of titanium tetraisopropoxide to the polyester reaction vessel equipped with a stirrer, nitrogen inlet pipe, Snyder tube and condenser, and use the upper part of the rectification pipe Heat slowly so that the temperature does not exceed 100°C, and keep the internal temperature at 220°C. When the acid value reached below 4 mgKOH / g, the esterification reaction was terminated to obtain a polyester polyol "EGoPA 1100" with a number average molecular weight of 1100. The number of repeating units of this polyester polyol was n=4.82, and the permeability factor value of the residues other than the terminal hydroxyl group was 55.4. The hydroxyl value is 102.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com