A high temperature resistant aluminum alloy sacrificial anode material and its preparation method and application

A sacrificial anode and aluminum alloy technology, applied in the field of Ce, La rare earth aluminum alloy sacrificial anode materials, can solve the problems of uneven corrosion, poor electrochemical performance, low current efficiency, etc., and achieve excellent electrochemical performance and improved fluidity. , to solve the effect of low current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

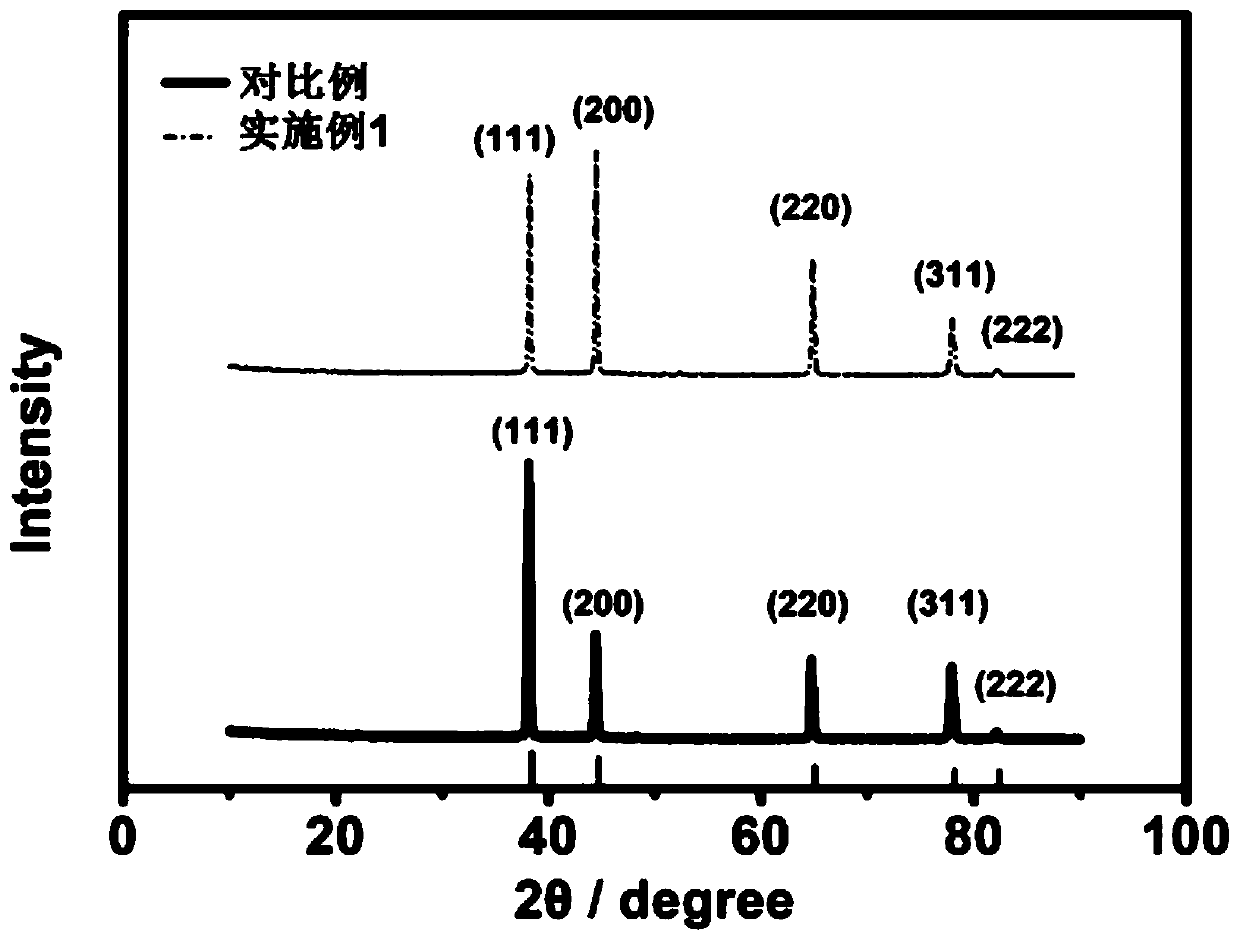

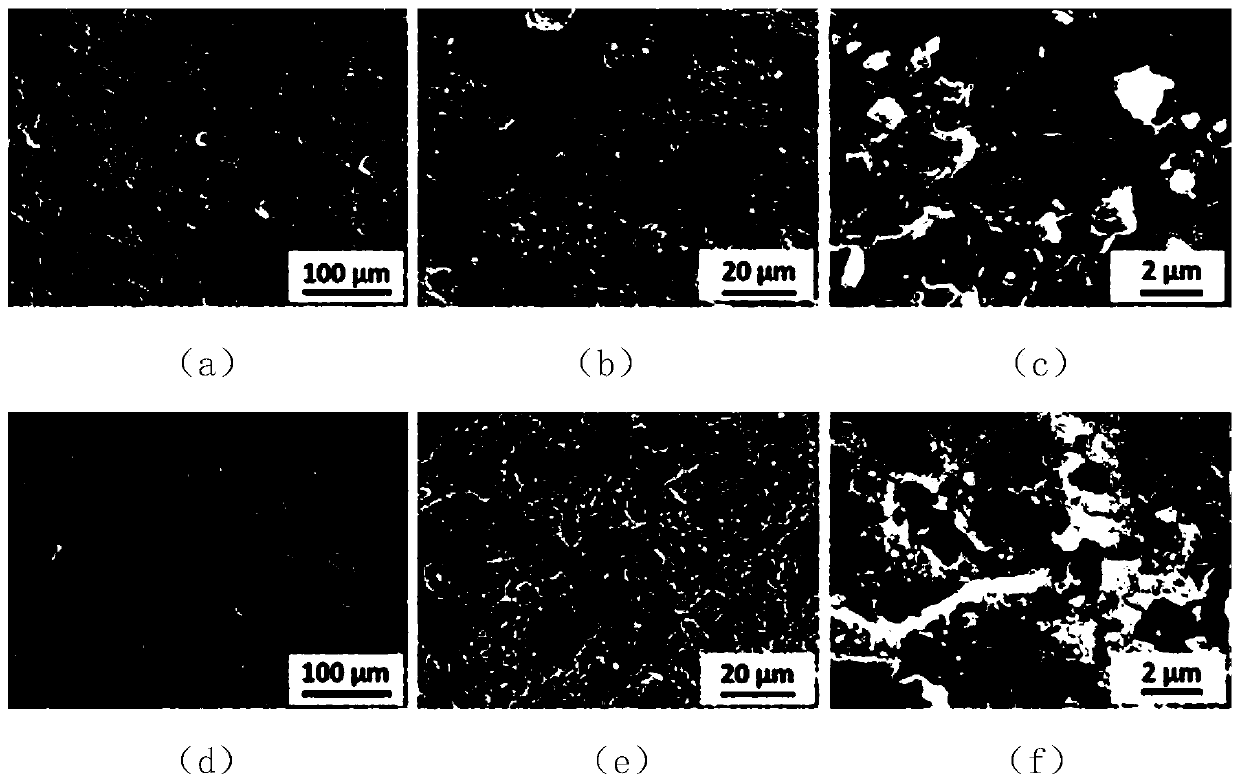

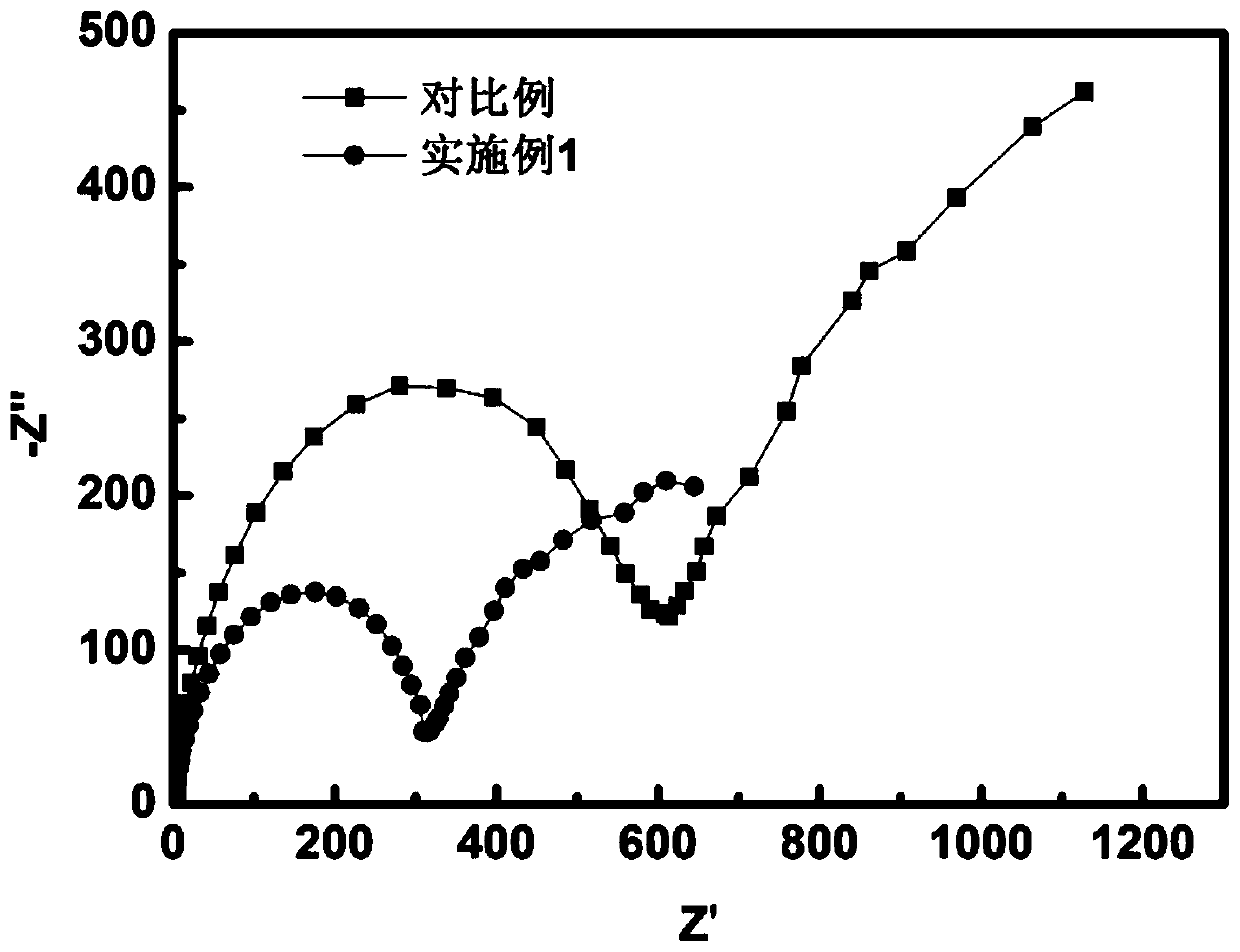

Embodiment 1

[0026] The Ce, La aluminum alloy sacrificial anode material of this embodiment is composed of the following components in mass percentage: Zn 4.71%, In 0.05%, Mg 2.31%, Si 0.10%, Ce 0.08%, La 0.03%, the balance For Al and unavoidable impurities.

[0027] The preparation method of the Ce, La aluminum alloy sacrificial anode material of this embodiment is to take alloy raw materials pure zinc (Zn), pure indium (In), pure magnesium (Mg), pure aluminum (Al ), aluminum-cerium master alloy (Al-Ce), aluminum-lanthanum master alloy (Al-La) and aluminum-silicon master alloy (Al-Si), take 471 parts of pure zinc (Zn), take 5 parts of pure indium (In), Take 231 parts of pure magnesium (Mg), 67 parts of aluminum-cerium master alloy (Al-Ce), 25 parts of aluminum-lanthanum master alloy (Al-La), 50 parts of aluminum-silicon master alloy (Al-Si), and 9151 parts of aluminum (Al) were smelted in a graphite crucible and an induction furnace to obtain a molten liquid; under the protection of argo...

Embodiment 2

[0029] The Ce, La aluminum alloy sacrificial anode material of this embodiment is composed of the following components in mass percentage: Zn 4.57%, In 0.05%, Mg 2.29%, Si 0.10%, Ce 0.16%, La 0.06%, the balance For Al and unavoidable impurities.

[0030]The preparation method of the Ce, La aluminum alloy sacrificial anode material of this embodiment is to take alloy raw materials pure zinc (Zn), pure indium (In), pure magnesium (Mg), pure aluminum (Al ), aluminum-cerium master alloy (Al-Ce), aluminum-lanthanum master alloy (Al-La) and aluminum-silicon master alloy (Al-Si), take 457 parts of pure zinc (Zn), take 5 parts of pure indium (In), Take 229 parts of pure magnesium (Mg), take 133 parts of aluminum-cerium master alloy (Al-Ce), get 50 parts of aluminum-lanthanum master alloy (Al-La), get 50 parts of aluminum-silicon master alloy (Al-Si), and take pure 9076 parts of aluminum (Al) were smelted in a graphite crucible and an induction furnace to obtain a melt; under the prot...

Embodiment 3

[0032] The Ce, La aluminum alloy sacrificial anode material of this embodiment is composed of the following components in mass percentage: Zn4.26%, In0.05%, Mg2.19%, Si0.17%, Ce0.45%, La0.45%, the balance For Al and unavoidable impurities.

[0033] The preparation method of the Ce, La aluminum alloy sacrificial anode material of this embodiment is to take alloy raw materials pure zinc (Zn), pure indium (In), pure magnesium (Mg), pure aluminum (Al ), aluminum-cerium master alloy (Al-Ce), aluminum-lanthanum master alloy (Al-La) and aluminum-silicon master alloy (Al-Si), take 426 parts of pure zinc (Zn), take 5 parts of pure indium (In), Take 219 parts of pure magnesium (Mg), take 375 parts of aluminum-cerium master alloy (Al-Ce), get 375 parts of aluminum-lanthanum master alloy (Al-La), get 85 parts of aluminum-silicon master alloy (Al-Si), and take pure 8515 parts of aluminum (Al) were smelted in a graphite crucible and an induction furnace to obtain a molten liquid; under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com