Titanium concentrate and vanadium-iron concentrate bulk concentrate acidic oxidized pellet and preparing method thereof

A technology of mixing concentrates and oxidizing pellets, applied in the field of metallurgy, can solve problems such as incomplete supporting industries, low thermal efficiency and titanium recovery rate, and difficult recycling, achieving considerable application prospects and improved metallurgical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

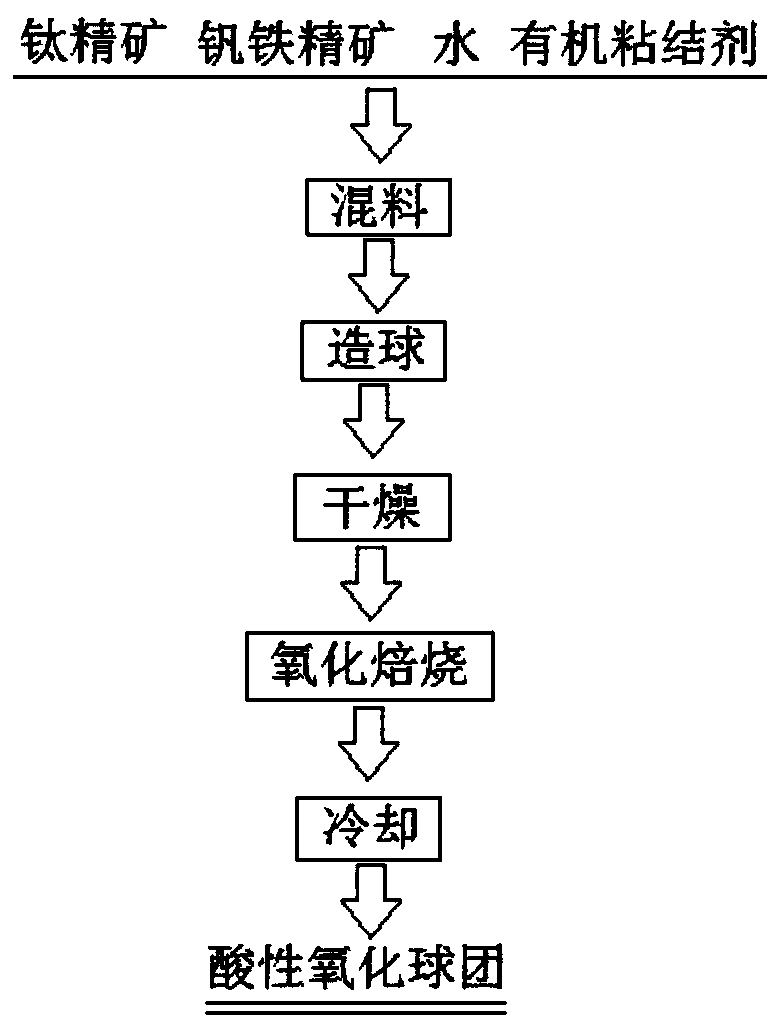

[0023] Specifically, a method for preparing acidic oxidation pellets of titanium concentrate and ferrovanadium concentrate mixed concentrate, the method comprises the following steps:

[0024] A. Mix titanium concentrate, ferrovanadium concentrate, water and organic binder evenly to obtain a mixture;

[0025] B. The mixture obtained in step A is pelletized to obtain wet pellets, and after the wet pellets are dried, dry pellets are obtained;

[0026] C. The dried pellets obtained in step B are oxidized and roasted, and cooled to obtain acidic oxidation pellets of titanium concentrate and ferrovanadium concentrate mixed concentrate.

[0027] The method of the present invention simultaneously utilizes the fine-grained titanium concentrate and vanadium-iron concentrate produced in the Panxi area, adjusts the ratio of the two to make acidic oxidation pellets with good metallurgical properties, and recycles the iron in them at the same time. , titanium and vanadium resources; titan...

Embodiment 1

[0039]Weigh 6.0 kg of titanium concentrate (accounting for 80.0%) according to the mass ratio of raw materials, of which -200 mesh accounts for 75.5% in its particle size composition, 1.5 kg of ferrovanadium concentrate (accounting for 20.0%), of which -200 mesh accounts for 82.3% of its particle size composition , add 220 grams of PVA (accounting for 2.9% of the total mass of titanium concentrate and vanadium concentrate), add 750g water (accounting for 10% of the total mass of titanium concentrate and vanadium concentrate), mix 15 minutes, get mixing material; use a disc pelletizer to pelletize the mixture to obtain wet pellets with a diameter of 9 to 23 mm. The pelleting rate of the wet pellets is measured to be 87.5%, and the water content is 15.5%. Random sampling of 20 wet pellets The average compressive strength of the pellets was measured to be 3.2N / ball, and the 0.5m high drop strength was 36 times / ball; the wet pellets were dried in a drying oven at a drying temperatu...

Embodiment 2

[0041] Weigh 6.0 kg of titanium concentrate (accounting for 66.7%) according to the mass ratio of raw materials, of which -200 mesh accounts for 82.5% of its particle size composition, 3.0 kg of ferrovanadium concentrate (accounting for 33.3%), of which -200 mesh accounts for 90.2% of its particle size composition , add 130 grams of PVA (accounting for 1.4% of the total mass of titanium concentrate and vanadium concentrate), add 1080g water (accounting for 12% of the total mass of titanium concentrate and vanadium concentrate), mix 12 minutes, get Mixed material; use a disc pelletizer to pellet the mixed material to obtain wet pellets with a diameter of 9 to 25 mm. The measured pelleting rate of the wet pellets is 93.8%, and the water content is 17.1%. Randomly sample 20 The average compressive strength of the wet pellets is 3.8N / ball, and the 0.5m high drop strength is 49 times / ball; the wet pellets are dried in a drying oven at a drying temperature of 150°C and a drying time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com