Steel-based titanium coating and preparation method and application thereof

A titanium coating and steel-based technology, applied in the coating, metal material coating process, etc., can solve the problems that cannot meet the market demand, affect the bonding performance of the steel substrate and the titanium coating, and achieve good process controllability, Improved toughness and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

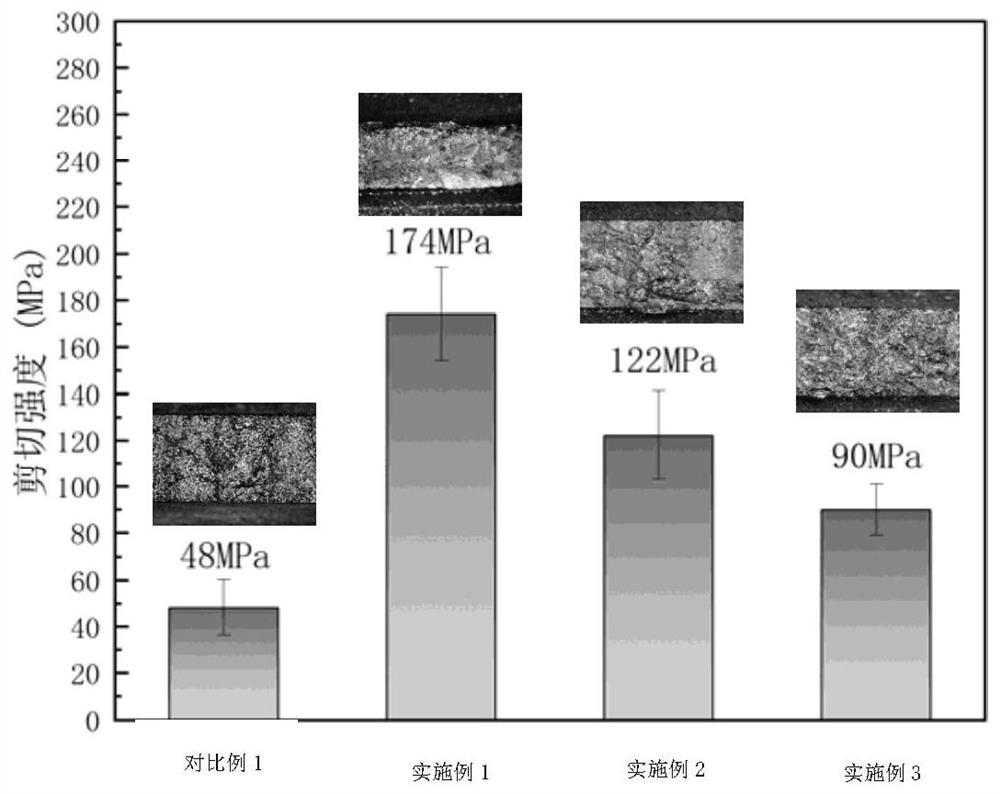

Embodiment 1

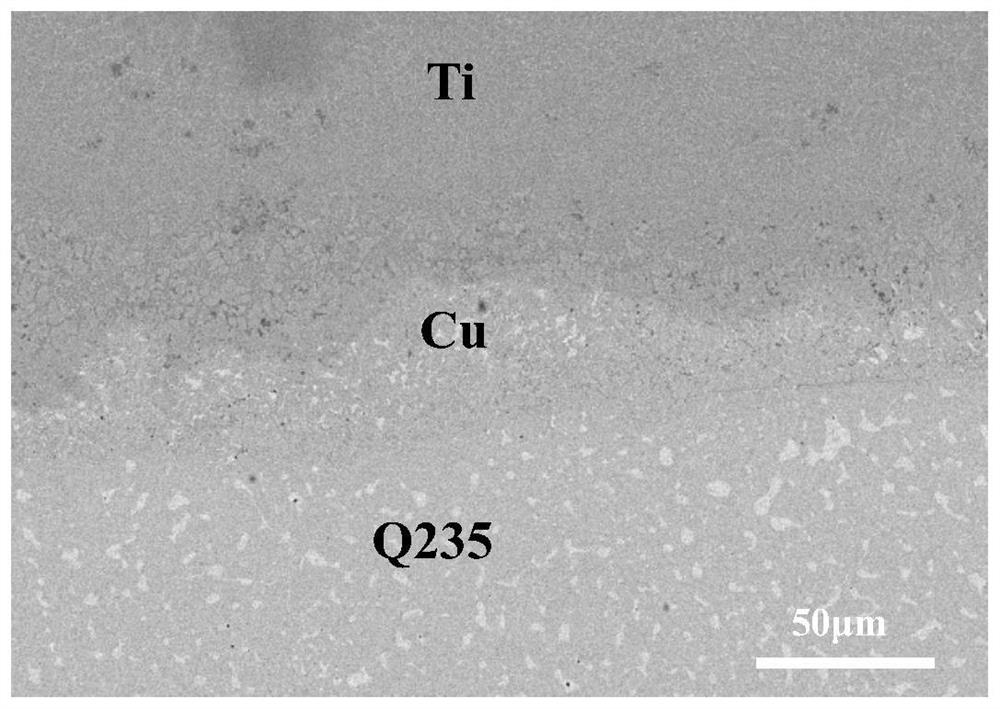

[0036] A steel-based titanium coating sequentially includes a steel base layer, a copper intermediate layer and a titanium coating.

[0037] A method for preparing a steel-based titanium coating, comprising the following steps:

[0038] S0: Select Q235 steel plate as the base material, use a grinder to remove the scale on the surface of the steel plate, rinse it with alcohol, dry it, and put it on the workbench;

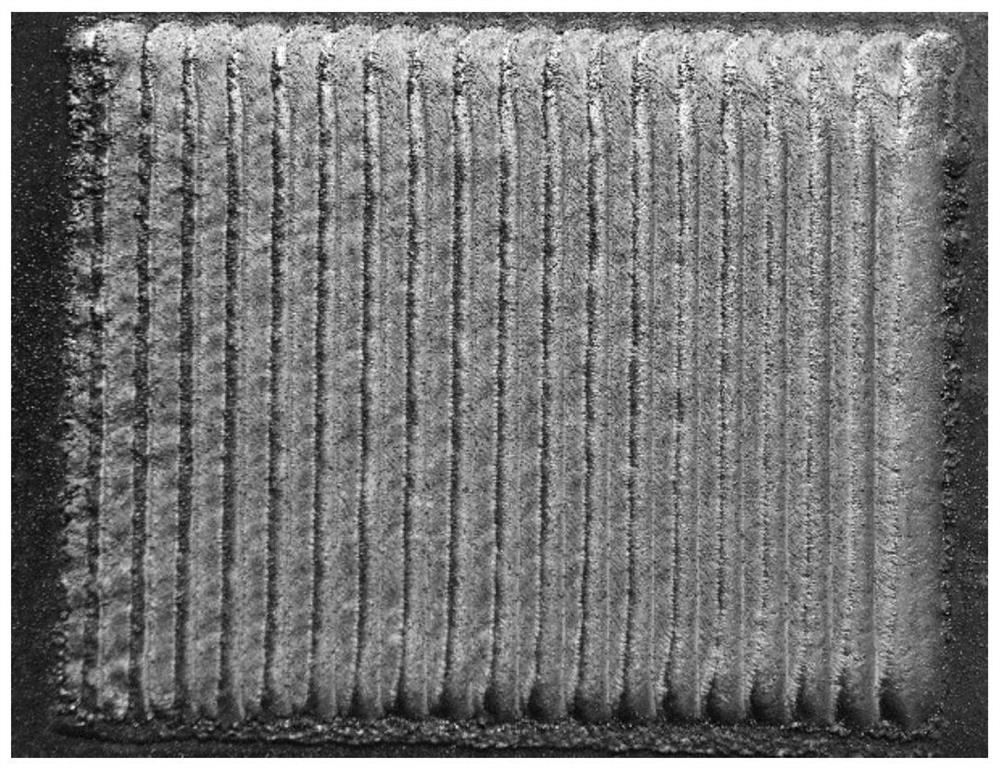

[0039] S1: Select spherical pure copper powder with a particle size of 100 μm, adopt laser cladding technology, set the laser power to 1200W, powder feeding rate to 3g / min, control the cladding speed to 10mm / s, and clad a layer of copper on the surface of the steel substrate Powder, to obtain copper cladding layer;

[0040] S2: Use an angle grinder to remove oxides on the surface of the copper cladding layer to obtain a copper intermediate layer;

[0041] S3: Select spherical TA1 powder with a particle size of 100μm, set the laser power to 1200W, the powder feeding...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is that in embodiment 2, the powder feeding rate of copper powder in step S2 is 4.5 g / min. The finished product 2 of the steel-based titanium coating embodiment was obtained.

[0045] Wherein, in the obtained steel-based titanium coating example finished product 2, the thickness of the copper intermediate layer is 100 μm (the thickness before cladding the titanium coating is about 250 μm); the thickness of the titanium coating is 1200 μm.

Embodiment 3

[0047] The difference between embodiment 3 and embodiment 1 is that in embodiment 3, the powder feeding rate of copper powder in step S2 is 6 g / min. Example finished product 3 of the steel-based titanium coating was obtained.

[0048] Wherein, in the finished product 3 of the obtained steel-based titanium coating example, the thickness of the copper intermediate layer is 150 μm (the thickness before cladding the titanium coating is about 450 μm); the thickness of the titanium coating is 1200 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com