Ore distributing and mixing system based on ports

A batching system and feeding system technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve problems such as the decline of blast furnace index, high fuel ratio, and fluctuation of sinter composition, so as to reduce the cost of pig iron, and the batching system is accurate and stable The effect of raw material conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

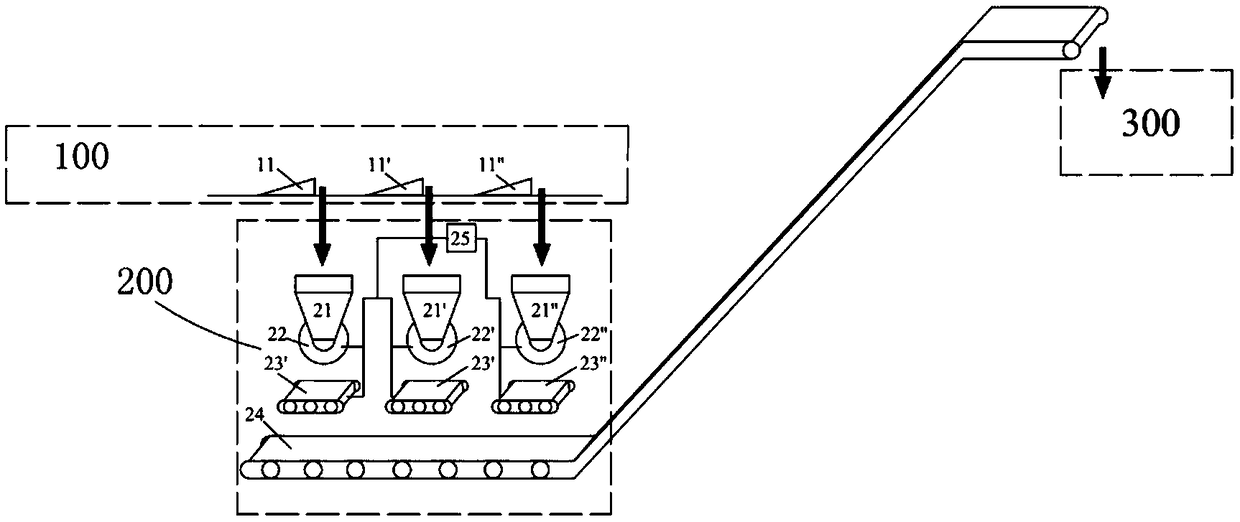

[0031] see figure 1 , a port-based iron ore batching and mixing system provided by the present invention includes a feeding system 100, a batching system 200, and a stockpiling system 300. The feeding system 100 and the stockpiling system 300 are arranged on the ground, so The batching system 200 is set in the basement below the ground;

[0032] The feeding system 100 includes a belt conveyor feeding system and / or a car feeding system; the belt conveyor feeding system or the car feeding system is connected to the iron ore raw material storage system of the port;

[0033]The batching system 200 includes: three batching bins 21 / 21' / 21", which are located below ground level; each batching bin 21 / 21' / 21" is equipped with a feeder 22 / 22' / 22" and An electronic belt scale 23 / 23' / 23"; the feeder 22 / 21' / 21" is respectively arranged under the batching bin 21 / 21' / 21", and the feeder 22 / 22' / The 22" feed port is respectively connected to the 21 / 21' / 21" discharge port of the batching bin...

specific Embodiment

[0039] After implementing the iron ore batching and mixing system provided by the present invention in a port in Shandong, the iron ore mixture was obtained, and the quality of the iron ore mixture was tested in multiple ways.

[0040] (1) Iron ore mixing material batching scheme: see Table 1.

[0041] Table 1

[0042]

item name

Proportion

Quantity

Material 1

plug ore crushing powder

10%

3000 tons

Material 2

mauritanian powder

14%

4200 tons

Material 3

FMG mixed powder

33.3%

10000 tons

Material 4

Pellet crushing

9.7%

2900 tons

Material 5

card powder

7.3%

2200 tons

Material 6

Brazilian ore sifted powder

9%

2700 tons

Material 7

BRBF

16.7%

5000 tons

[0043] (2) Comparison (%) between the design index and the inspection index of each broken mixed powder intercepted during loading, see Table 2.

[0044] Table 2

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com