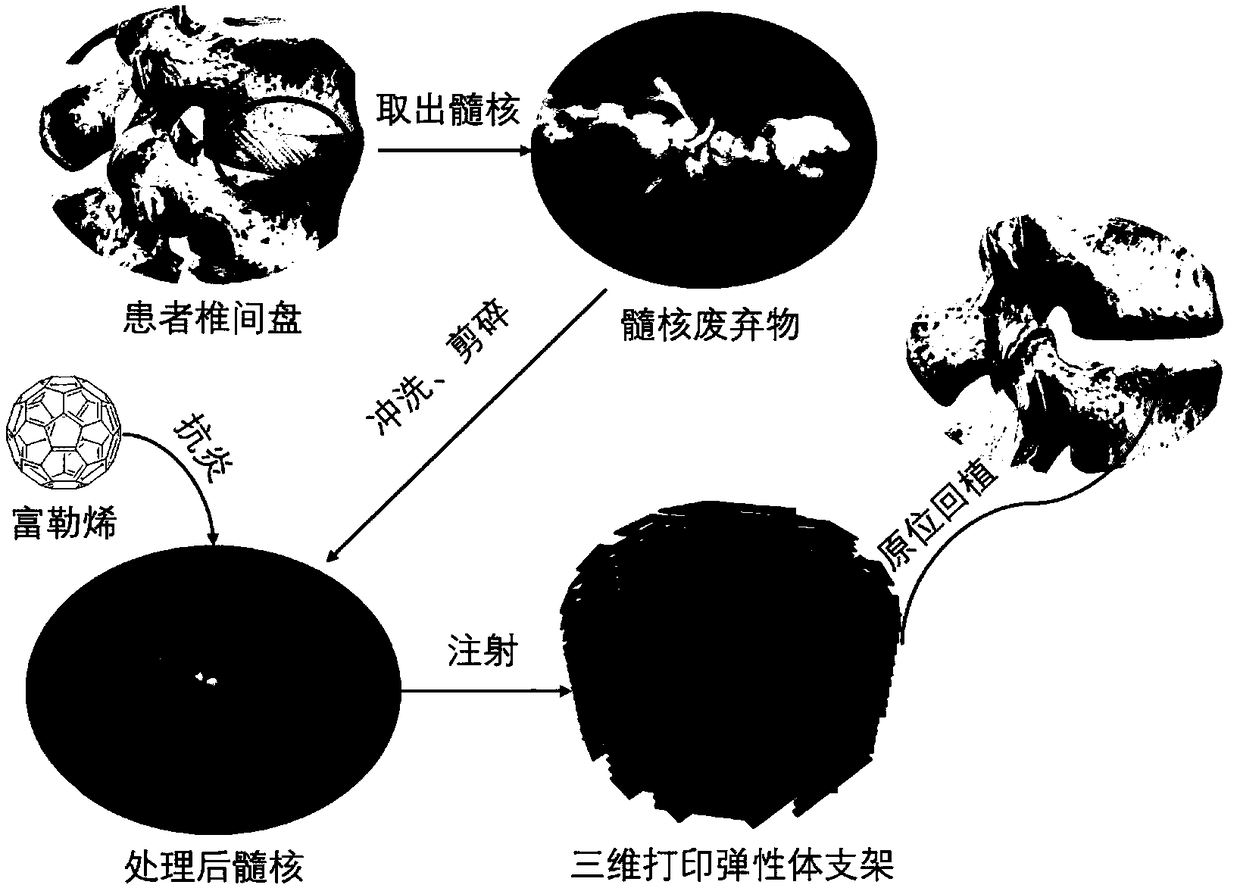

Method of preparing nucleus pulposus replantation body in combination with three-dimensional printing technology

A technology of three-dimensional printing and nucleus pulposus, which is applied in prosthetics, medical science, tissue regeneration, etc., to achieve good mechanical properties, long shelf life, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] S1. Preparation of elastomeric scaffold:

[0035] 1. Selection of materials: Measure an appropriate amount of polycaprolactone material and wait for the next step;

[0036] 2. Establishment of 3D model: Use 3D printing software to build a 3D model, then export the 3D model, save it, and wait for the next step;

[0037] 3. Printing of the 3D model: Add the polycaprolactone material measured in step 1 into the barrel of the 3D printing device, and then heat the polycaprolactone material in the barrel until the polycaprolactone material is completely After melting, start the printing program, and print the polycaprolactone material according to the three-dimensional model established in step 2 through the three-dimensional printing equipment, and wait until the printing is completed to obtain the polycaprolactone elastomer support, wherein the elastic support has a certain pore structure , waiting for the next step;

[0038] 4. Treatment of the elastomer support: use cob...

Embodiment 1

[0054] Using 3D printing software to construct a 3D model, the shape is cylindrical, with a diameter of 3 mm and a height of 5 mm. Export the stl format file and save it. Add polycaprolactone into the three-dimensional printing barrel, heat it to 100-150°C, and after it is completely melted, start the printing program to print and form. The diameter of the print head is 150 μm, the air pressure of the barrel during printing is 800KPa, and the layer height is 150 μm. The print path angle is 0 / 60. The printed polycaprolactone elastomer scaffold was sterilized by cobalt-60 radiation and stored in a dry, low-temperature sterile environment.

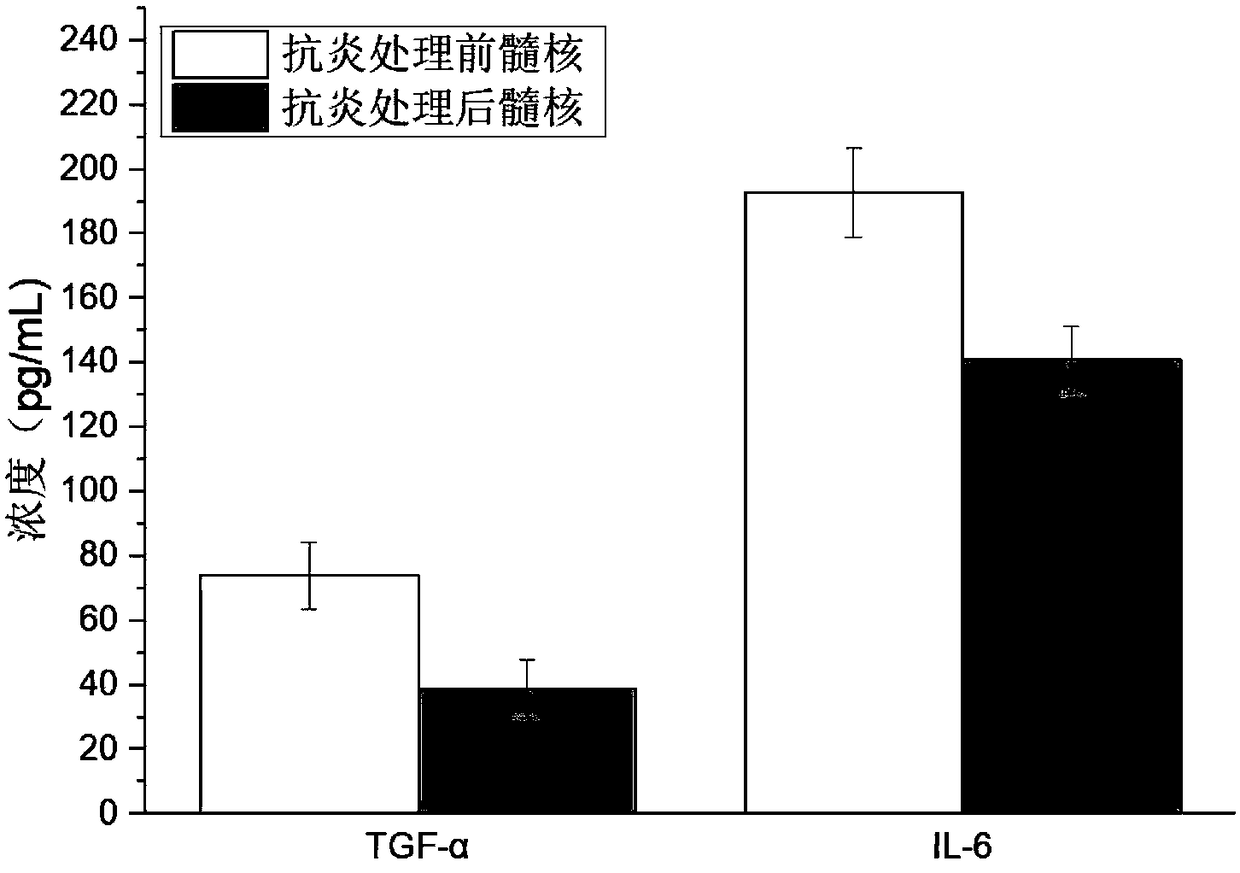

[0055] The nucleus pulposus waste removed during the operation was rinsed, shredded, and treated with anti-inflammation. In the washing step, the waste of the nucleus pulposus of the intervertebral disc is washed away with normal saline, and repeated several times. In the shredding step, the nucleus pulposus waste is shredded sufficiently...

Embodiment 2

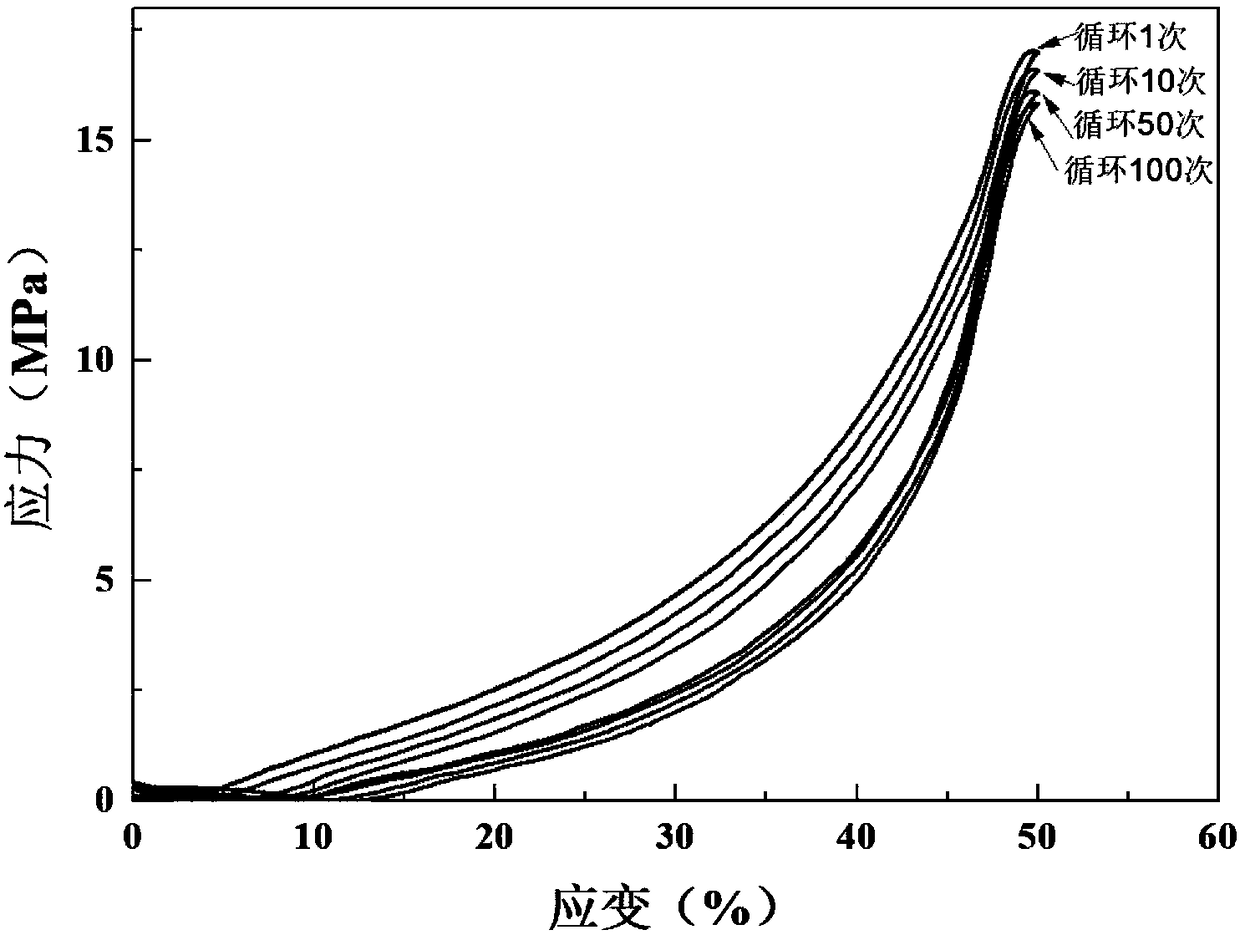

[0059] The radial mechanical performance test was carried out on the three-dimensionally printed elastomeric stent printed in Example 1. The test used a universal mechanical tester to cyclically compress the stent in the radial direction. During the test, the maximum deformation was 60%, and the compression rate was 10cm / min. A total of 100 cycles were performed. The stress-strain cycle curve is as figure 2 As shown, after up to 100 compression cycles, the scaffold still maintains good mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com