A kind of organic solar cell structure and preparation method based on dimethacrylate monomer

A technology of dimethacrylate and solar cells, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of lower fill factor and weaker electron extraction ability, and achieve simple process and method, and solve The problem of unstable shape and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

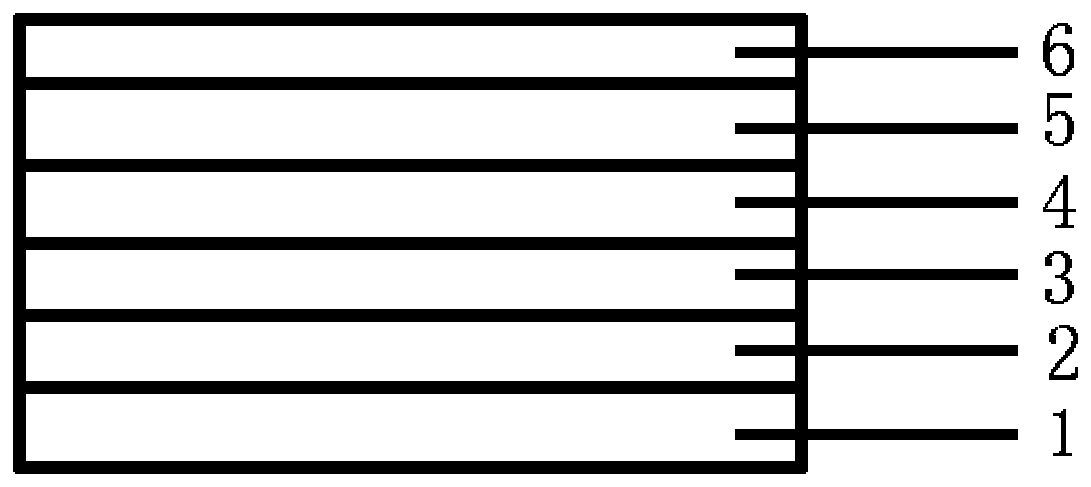

[0050] An organic solar cell structure based on dimethacrylate monomer, such as figure 1 As shown, from bottom to top, it includes transparent conductive substrate 1, ITO 2, electron transport layer 3, organic active layer 4, hole transport layer 5, metal electrode 6; organic active layer 4 includes fullerene: polymer polymerization Material, dimethacrylate monomer. A layer of ITO 2 is plated on the transparent conductive substrate 1.

[0051] The addition of the dimethacrylate monomer to the organic active layer 4 solves the problem of instability in the morphology of the organic active layer 4, so that the organic active layer 4 has good thermal stability. And the mechanical properties of the morphology are improved, which provides technical assistance for flexible printing.

[0052] Based on dimethacrylate monomers, it is prone to polymerization reaction under the action of heat and ultraviolet rays to form an insoluble insoluble acrylic polymer with a network structure. The n...

Embodiment 2

[0054] According to the structure of an organic solar cell based on dimethacrylate monomer according to embodiment 1, the difference lies in:

[0055] Fullerene: high molecular polymer is P3HT: PCBM or PTB7: PCBM; dimethacrylate monomer is (2) ethoxylated bisphenol A dimethacrylate (BPA2EODMA), (3) ethoxylated bisphenol A Dimethacrylate (BPA3EODMA), (4) ethoxylated bisphenol A dimethacrylate (BPA4EODMA), (5) ethoxylated bisphenol A dimethacrylate (BPA5EODMA), (6) ethoxylated bisphenol A dimethacrylate (BPA6EODMA), (10) ethoxylated bisphenol A dimethacrylate (BPA10EODMA), (30) ethoxylated bisphenol A dimethacrylate, 1,4-butanediol dimethyl Base acrylate, 1,6-hexanediol dimethacrylate, 1,4-cyclohexane dimethanol dimethacrylate, ethylene glycol dimethacrylate, diethylene glycol dimethacrylate , Triethylene glycol dimethacrylate, polyethylene glycol (200) dimethacrylate, polyethylene glycol (400) dimethacrylate, polyethylene glycol (600) dimethacrylate, Polyethylene glycol (1000) d...

Embodiment 3

[0060] According to the structure of an organic solar cell based on dimethacrylate monomer according to embodiment 2, the difference is that the mass ratio of the dimethacrylate monomer to the organic active layer 4 is 10wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com