Vacuum packaging type powder fuel conveying device

A technology for vacuum packaging and fuel delivery, which is applied in the direction of conveying bulk materials, packaging, conveyors, etc. It can solve the problems of unstable powder flow, uneven force on the piston, easy jamming, etc., and achieve high filling rate, convenient storage and The effect of convenient transportation and filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

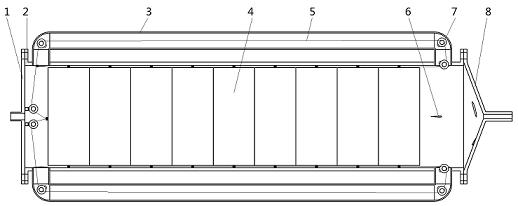

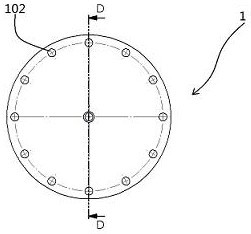

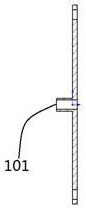

[0022] A vacuum-packed powder fuel conveying device is characterized in that it includes a powder fuel storage tank, a bag breaking blade 6, a vacuum-packed powder cake 4, a bag collection pipe 3, a roller 7 and a nylon rope 5, and the powder fuel storage tank includes a storage tank. Tank rear end cover 1, storage tank straight section 2, storage tank front end cover 8, the storage tank rear end cover 1, storage tank straight section 2, and storage tank front end cover 8 are connected by flanges to form a powder fuel storage tank , used to fill the vacuum-packed powder cake 4, the rear end cover 1 of the storage tank is provided with a central air inlet 101 of the rear end cover and a connecting flange 102, and the straight section 2 of the storage tank is respectively provided with two front and rear flange attachments. The through holes 201 are arranged symmetrically and are used to connect the bag collection pipe 3. The front end cover 8 of the storage tank is a converging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com