Visible-short wave infrared detector and preparation method thereof

A short-wave infrared and detector technology, applied in the field of photon detection, can solve problems such as differences in thermal expansion coefficients, poor reliability, and limited stability of infrared detection systems, achieving low cost and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

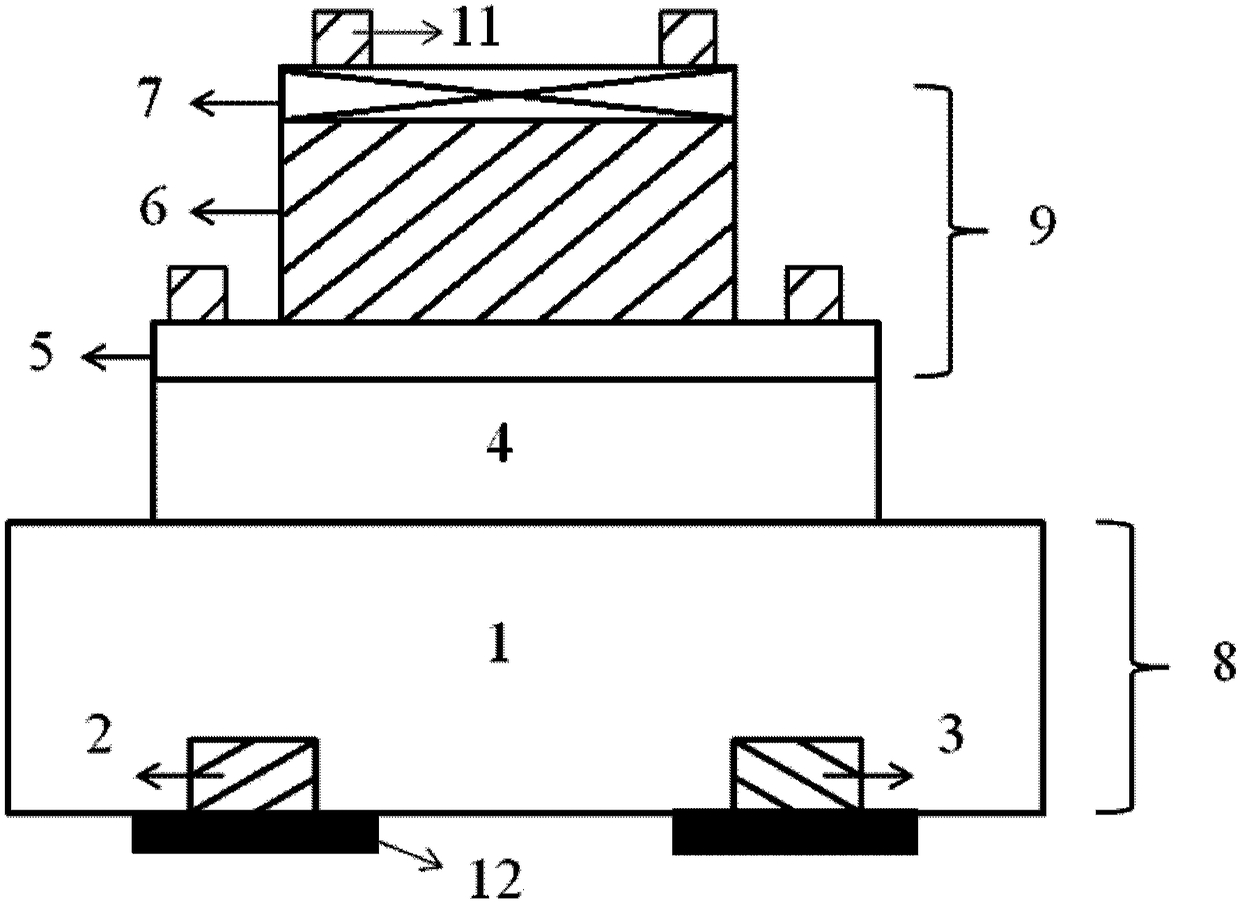

[0012] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

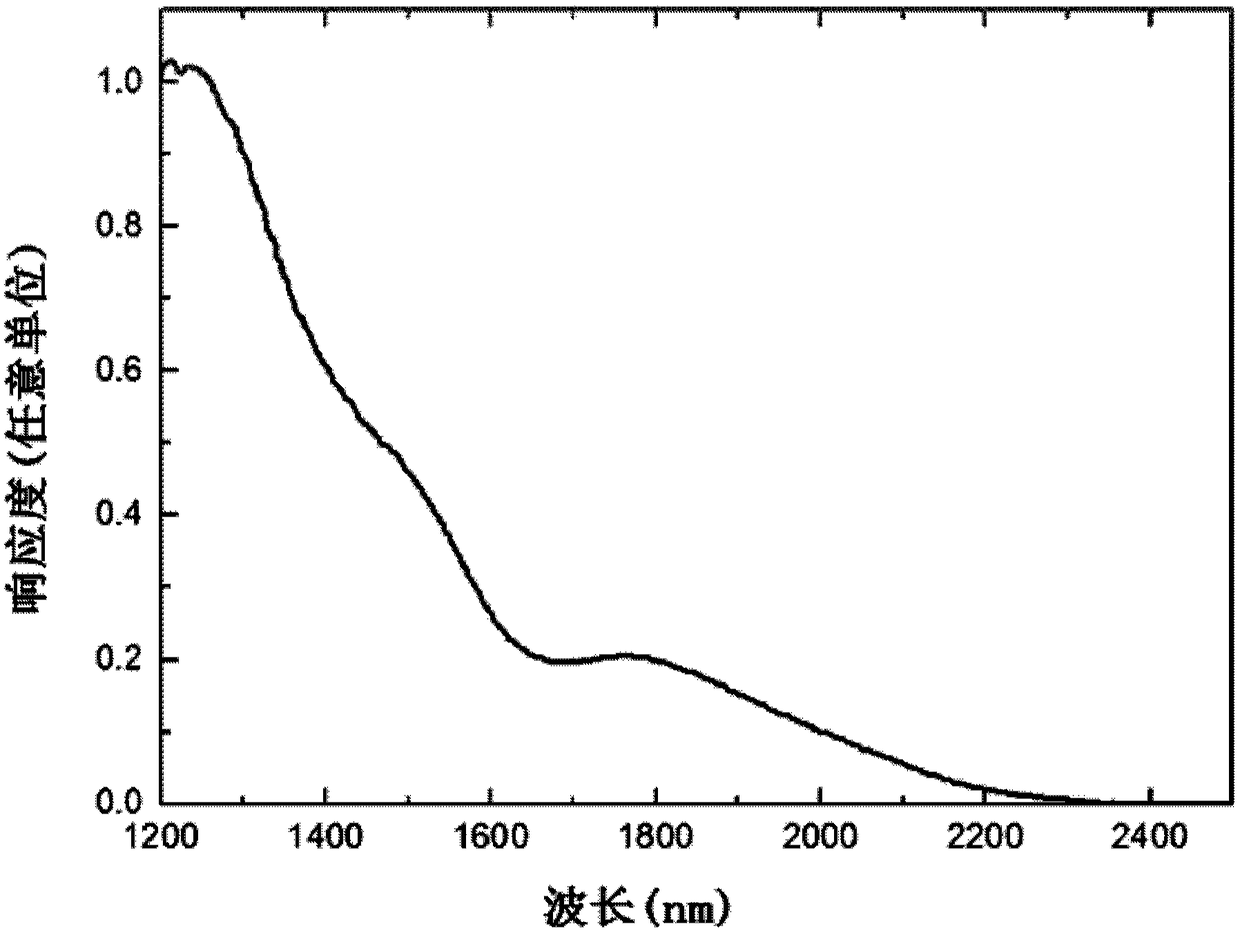

[0013] The CMOS process of Si is very mature and can easily realize CCD cameras with megapixels or even tens of millions of pixels. Silicon is also an ideal material for preparing visible light detectors. The introduction of Sn, Ge into the Ge material lattice 1-x Sn x The band gap will be narrowed. The band structure and Sn composition change law are as follows: Eg(Ge 1-x Sn x )=Eg Ge (1-x)+Eg Sn x-bx(1-x), where Eg Ge And Eg Sn Are the direct band gap energy of Ge and Sn, respectively, and b is the bending coefficient, which is about 2.42. For example, when the Sn content is 8.5%, Ge 1- x Sn x The direct band gap energy of the material is about 0.51eV, and the detection wavelength can reach 2.4μm. It is a good s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com