High-corrosion-resistance marine aluminum alloy surface metal-organic skeleton film treatment liquid and using method thereof

A technology of aluminum alloy surface and organic framework, which is applied in the coating process of metal materials, etc., can solve the problems of paint or powder adhesion performance decline and film layer difference, so as to avoid the limitation of batch production, improve corrosion resistance and Adhesion, the effect of optimizing the film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

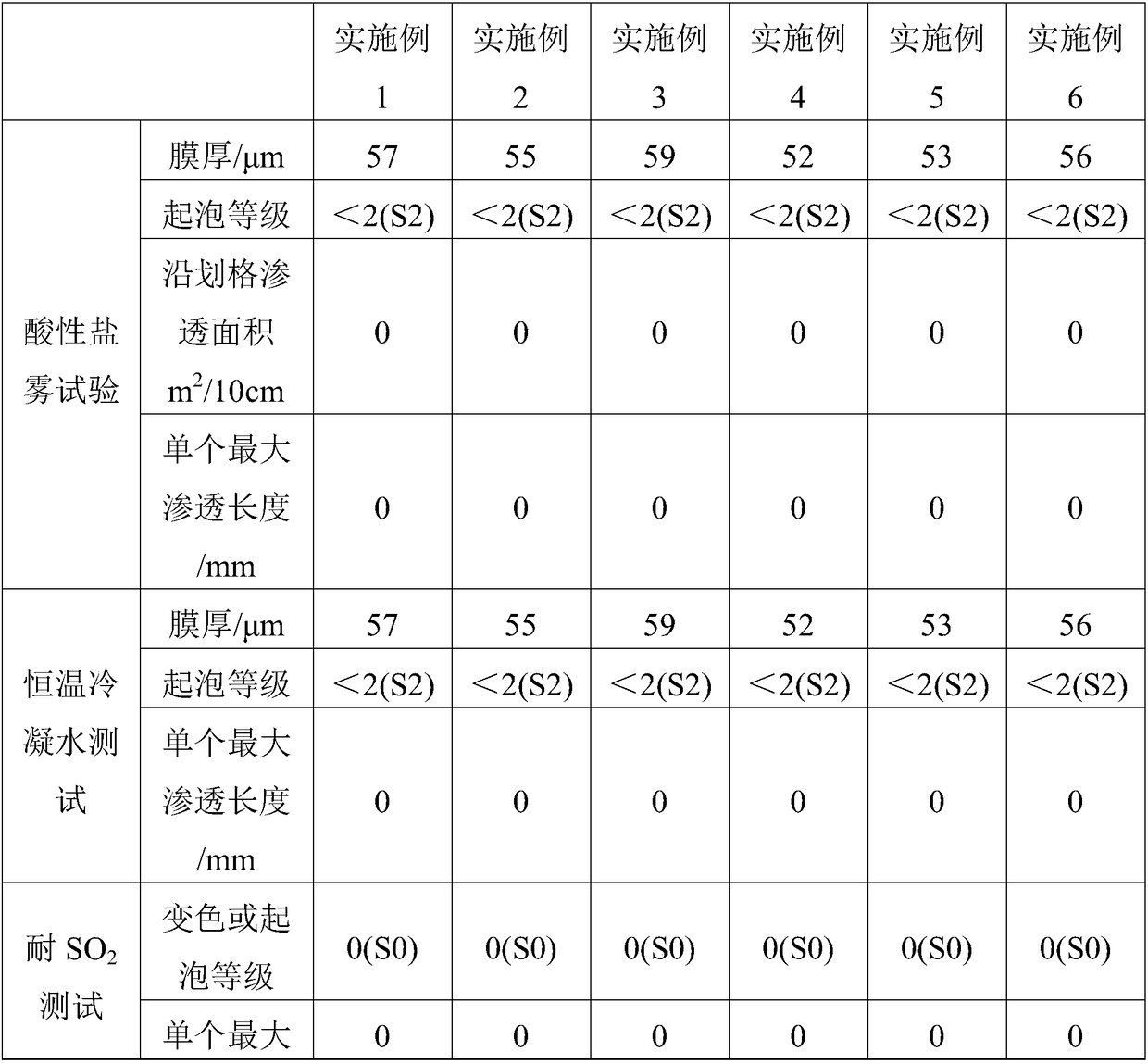

Examples

Embodiment 1

[0025] A metal-organic framework film treatment solution on the surface of a high corrosion-resistant marine aluminum alloy, the treatment solution is prepared from the following components: 1000ppm fluozirconic acid with a concentration of 45%, 600ppm fluotitanic acid with a concentration of 50%, difluorotitanic acid Manganese chloride 30ppm, glucose 400ppm, concentration of 50% sodium sulfate 10ppm, the balance is water. Adjust the pH value of the treatment solution to 4.

[0026] In this embodiment, the method of using the metal-organic framework film treatment liquid on the surface of the high corrosion-resistant marine aluminum alloy is used to form a framework film on the surface of the marine aluminum alloy. The specific preparation process is as follows:

[0027] (1) Polish the surface of the aluminum alloy with silicon carbide water sandpaper until the surface roughness is below 10 μm, soak it in an acidic degreasing and degreasing aqueous solution for 6 minutes, then...

Embodiment 2

[0031] A metal-organic framework film treatment solution on the surface of a high-corrosion-resistant marine aluminum alloy. The treatment solution is prepared from the following components: 100 ppm of fluorozirconic acid with a concentration of 45%, 800 ppm of fluorotitanic acid with a concentration of 50%, difluoro Manganese chloride 90ppm, glucose 100ppm, concentration of 50% sodium sulfate 10ppm, the balance is water. Adjust the pH value of the treatment solution to 3.

[0032] In this embodiment, the method of using the metal-organic framework film treatment liquid on the surface of the high corrosion-resistant marine aluminum alloy is used to form a framework film on the surface of the marine aluminum alloy. The specific preparation process is as follows:

[0033] (1) Polish the surface of the aluminum alloy with silicon carbide water sandpaper until the surface roughness is below 10 μm, soak it in an acid degreasing and degreasing aqueous solution for 3 minutes, rinse i...

Embodiment 3

[0037] A metal-organic framework film treatment solution on the surface of a high corrosion-resistant marine aluminum alloy, the treatment solution is prepared from the following components: 1200ppm of fluorozirconic acid with a concentration of 45%, 200ppm of fluorotitanic acid with a concentration of 50%, difluoro Manganese chloride 100ppm, glucose 500ppm, concentration of 50% sodium sulfate 20ppm, the balance is water. Adjust the pH value of the treatment solution to 6.

[0038] In this embodiment, the method of using the metal-organic framework film treatment liquid on the surface of the high corrosion-resistant marine aluminum alloy is used to form a framework film on the surface of the marine aluminum alloy. The specific preparation process is as follows:

[0039] (1) Polish the surface of the aluminum alloy with silicon carbide water sandpaper until the surface roughness is below 10 μm, soak it in an acid degreasing and degreasing aqueous solution for 2 minutes, rinse i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com