A kind of delayed fracture resistant alloy cold heading steel wire rod and its production method

A technology of resistance to delayed fracture and cold heading steel, applied in the field of alloy cold heading steel wire rod and its production, can solve the problems of total decarburization of surface structure, high requirements for delayed fracture ability and low quality, and achieve good delayed fracture resistance. , the effect of improving the service life and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

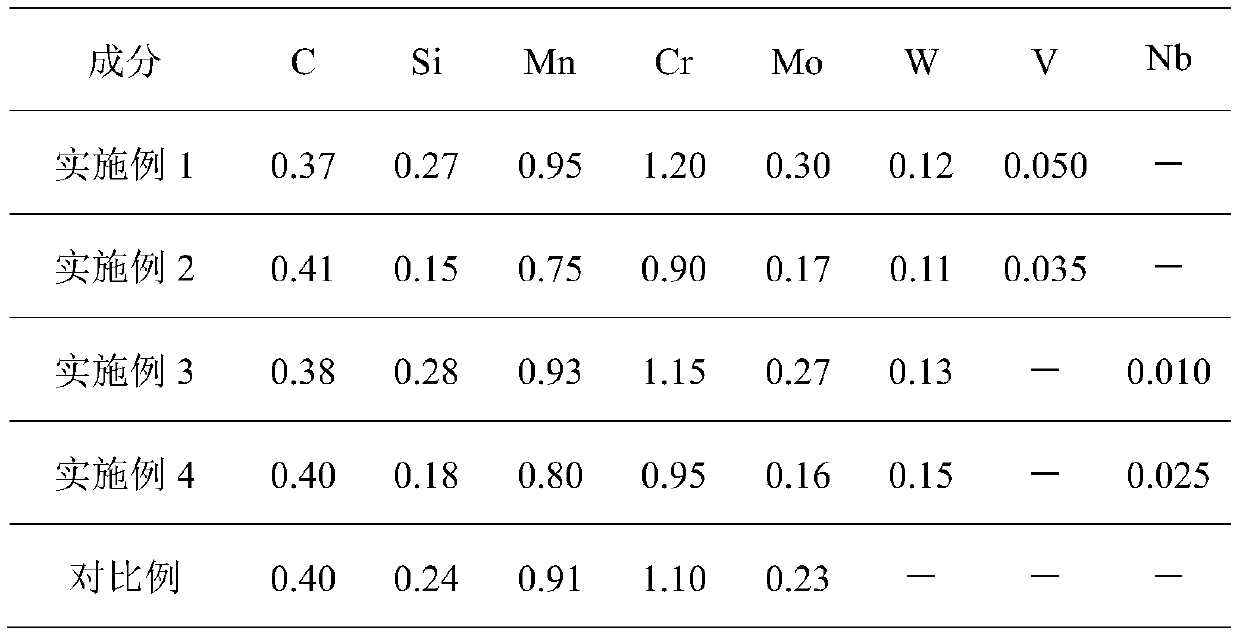

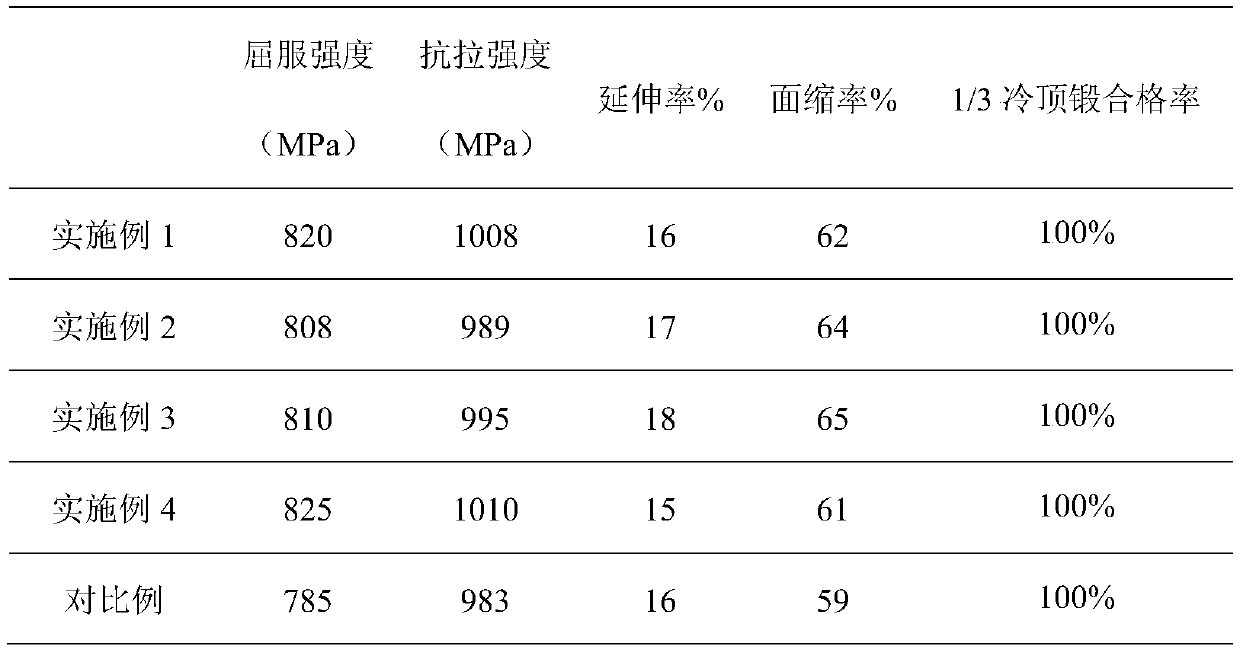

Embodiment 1

[0039]In this example, the chemical composition of carbon-chromium-molybdenum cold-heading steel is designed according to the technical solution of the present invention. After smelting, it is cast into a bloom with a cross-sectional size of 280×380mm, and the degree of superheat is 26°C; the current intensity of electromagnetic stirring in the mold is 400A. A 280×380mm bloom is heated and rolled into a billet with a cross-sectional size of 155×155mm, and the surface defects of the billet are ground.

[0040] Billets are rolled on a high speed wire rod mill Wire rod, the rolling process is as follows:

[0041] 1) The furnace temperature of the first stage of the heating furnace is 900°C; the temperature of the second stage is 1100°C; the upper soaking section is 1050°C; the lower soaking section is 1020°C, and the air-fuel ratio is 2.3;

[0042] 2) Control the starting rolling temperature to 960°C, the finish rolling inlet temperature to 910°C, the sizing inlet temperature t...

Embodiment 2

[0045] In this example, the chemical composition of medium-carbon chromium-molybdenum cold heading steel is designed according to the technical solution of the present invention. After smelting, it is poured into a bloom with a cross-sectional size of 280×380mm. The degree of superheat is 25°C. 400A, heating and rolling a 280×380mm bloom into a billet with a cross-section of 155×155mm, and grinding the surface defects of the billet.

[0046] Billets are rolled on a high speed wire rod mill Wire rod, the rolling process is as follows:

[0047] 1) The first-stage furnace temperature of the heating furnace is 910°C; the second-stage furnace temperature is 1120°C; the upper soaking section is 1040°C; the lower soaking section is 1020°C, and the air-fuel ratio is 2.4;

[0048] 2) Control the starting rolling temperature to 970°C, the finish rolling inlet temperature to 920°C, the sizing inlet temperature to 900°C, and the spinning temperature to 850°C;

[0049] 3) Stelmore air-c...

Embodiment 3

[0051] In this example, the chemical composition of the medium-carbon chromium-molybdenum cold heading steel is designed according to the technical solution of the present invention. After smelting, it is poured into a bloom with a section size of 280×380mm. The degree of superheat is 24°C. 400A, heating and rolling a 280×380mm bloom into a billet with a cross-section of 155×155mm, and grinding the surface defects of the billet.

[0052] Billets are rolled on a high speed wire rod mill Wire rod, the rolling process is as follows:

[0053] 1) The first-stage furnace temperature of the heating furnace is 890°C; the second-stage furnace temperature is 1090°C; the upper soaking section is 1045°C; the lower soaking section is 1025°C, and the air-fuel ratio is 2.5;

[0054] 2) Control the starting rolling temperature to 955°C, the finish rolling inlet temperature to 915°C, the sizing inlet temperature to 895°C, and the spinning temperature to 855°C;

[0055] 3) Stelmore air-coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com