High-strength bolt alloy material resistant to delayed fracture and manufacturing method of bolt

A technology of high-strength bolts and alloy materials, which is applied in the manufacture of bolts and the field of high-strength bolt alloy materials. It can solve the problems that the delayed fracture of bolts cannot be improved, and achieve improved corrosion resistance and surface finish, good resistance to delayed fracture, and enhanced The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

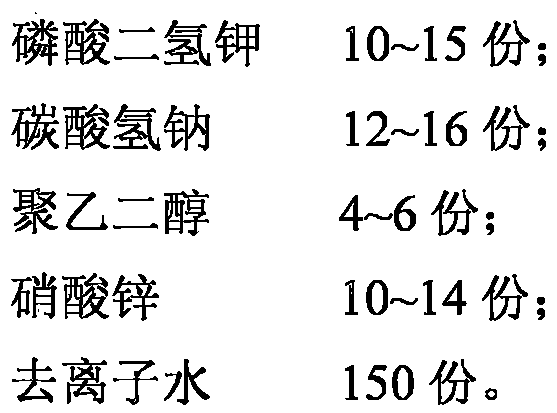

Method used

Image

Examples

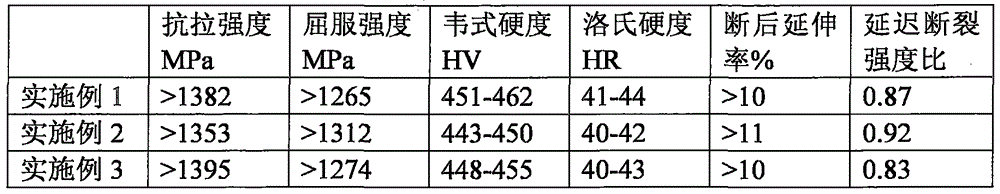

Embodiment 1

[0045] The bolt alloy material of the present embodiment includes the following chemical composition in weight percentage: C 0.4%, Si 0.2%, Mn 0.05%, P 0.01%, S 0.02%, Cu 0.1%, Co 0.25%, Ni 0.24%, Al 0.24% , Ti 0.18%, Mo 0.18%, V 0.1%, Sm 0.08%, Te 0.04%, NdFeB 0.08%, and the balance is iron and unavoidable impurity elements.

[0046] Adopt the manufacturing method of the bolt of the bolt alloy material of the present embodiment, comprise following 9 processing steps:

[0047] (1) Cast rod material; control the chemical composition of the rod material according to the above-mentioned ratio to make a rod material blank, and cast the rod material blank, wherein the temperature of the cast blank is reduced to 300 ° C, and then the temperature is reduced to 25 ° C / hour Heating at a heating rate of 600°C, holding for 2 hours, cooling to 300°C at a cooling rate of 30°C / hour, and completing a temperature control stage, then repeating the above temperature control stage twice, cooli...

Embodiment 2

[0060] The bolt alloy material of the present embodiment includes the following chemical composition in weight percentage: C 0.45%, Si0.15%, Mn 0.05%, P 0.015%, S 0.03%, Cu 0.13%, Co 0.27%, Ni 0.25, Al 0.21% , Ti0.2%, Mo 0.22%, V 0.14%, Sm 0.09%, Te 0.05%, NdFeB 0.12%, and the balance is iron and unavoidable impurity elements.

[0061] Adopt the manufacturing method of the bolt of the bolt alloy material of the present embodiment, comprise following 9 processing steps:

[0062] (1) Cast rod material; control the chemical composition of the rod material according to the above-mentioned ratio to make a rod material blank, and cast the rod material blank, wherein the temperature of the cast blank is reduced to 300 ° C, and then the temperature is reduced to 25 ° C / hour Heating rate to 700°C, holding temperature for 1.5 hours, cooling to 300°C at a cooling rate of 30°C / hour, and completing a temperature control stage, then repeating the above temperature control stage twice, coo...

Embodiment 3

[0075] The bolt alloy material of the present embodiment includes the following chemical composition in weight percentage: C 0.35%, Si0.12%, Mn 0.05%, P 0.02%, S 0.04%, Cu 0.3%, Co 0.30%, Ni 0.25, Al 0.1% , Ti0.18%, Mo 0.22%, V 0.12%, Sm 0.11%, Te 0.05%, NdFeB 0.13%, the balance is iron and unavoidable impurity elements.

[0076] Adopt the manufacturing method of the bolt of the bolt alloy material of the present embodiment, comprise following 9 processing steps:

[0077] (1) Cast rod material; control the chemical composition of the rod material according to the above-mentioned ratio to make a rod material blank, and cast the rod material blank, wherein the temperature of the cast blank is reduced to 300 ° C, and then the temperature is reduced to 25 ° C / hour Heat up to 680°C at a heating rate, hold for 2 hours, cool to 300°C at a cooling rate of 30°C / hour, and complete the temperature control stage once, then repeat the above temperature control stage twice, cool to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com