High-strength heat-treated steel bar and manufacturing method thereof

A steel, high-strength technology, applied in the field of high-strength heat-treated steel bars and its manufacturing, can solve the problems of reduced delayed fracture resistance, low yield ratio, low tensile strength and yield strength, etc., to improve delayed fracture resistance and improve safety. Reserve capacity, effect of low yield-to-strength ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

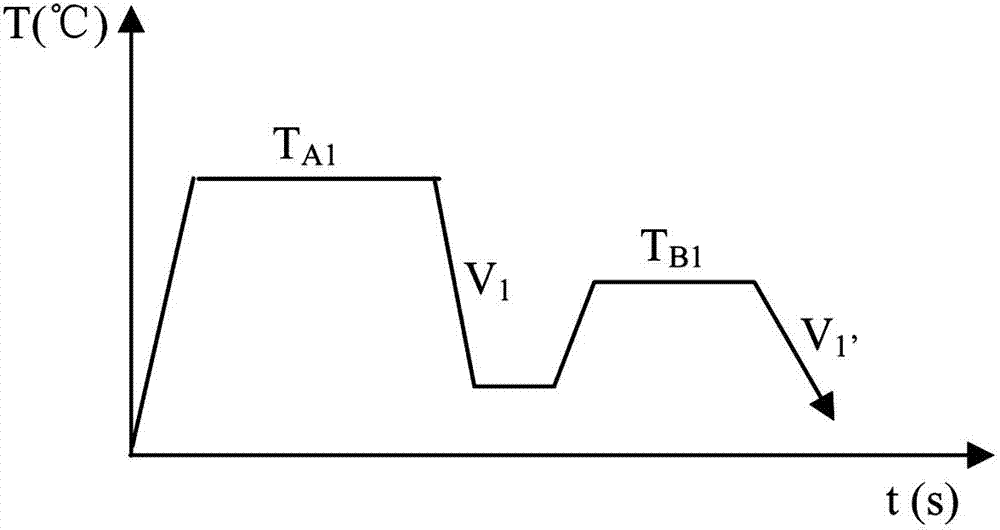

Embodiment 1

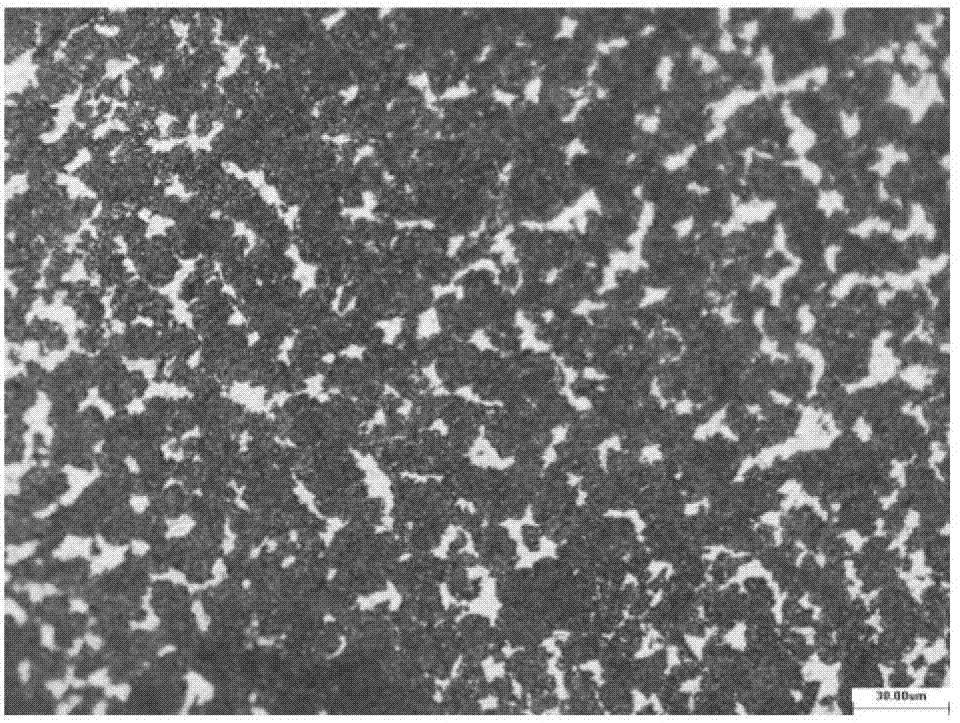

[0054] The chemical composition is: C 0.24%, Si 0.57%, Mn 1.40%, the rest is iron and unavoidable impurities industrial hot-rolled wire rod as raw material. The wire rod is drawn and deformed to form a spiral groove shape. Then, the steel bar is heated from room temperature to 900 ° C within 5 seconds using a high-frequency induction heating furnace, and then cooled. First, the steel bar is cooled to the two-phase region by fog cooling. Then the steel bar is cooled to a residual temperature of about 450°C. Then, the steel bar is subjected to isothermal treatment. During the isothermal treatment, the steel bar is pressurized to produce a bending strain of 0.8%. Water cooling is performed after the isothermal treatment for 10 seconds to cool the steel bar to 200°C. below ℃.

[0055] The obtained product of comparative example 1 has good strength and toughness. The yield strength of the steel bar is 1090MPa, and the tensile strength is 1195MPa. The elongation A after fracture is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com