Establishment of recombinant adeno-associated virus carrier production process

A virus vector and production process technology, applied in the field of establishment of recombinant adeno-associated virus vector production process, can solve the problems of many influencing factors, complicated operation, low immunogenicity, etc., and achieve stable and lasting expression, low immunogenicity, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Preparation of rAAV vector particles

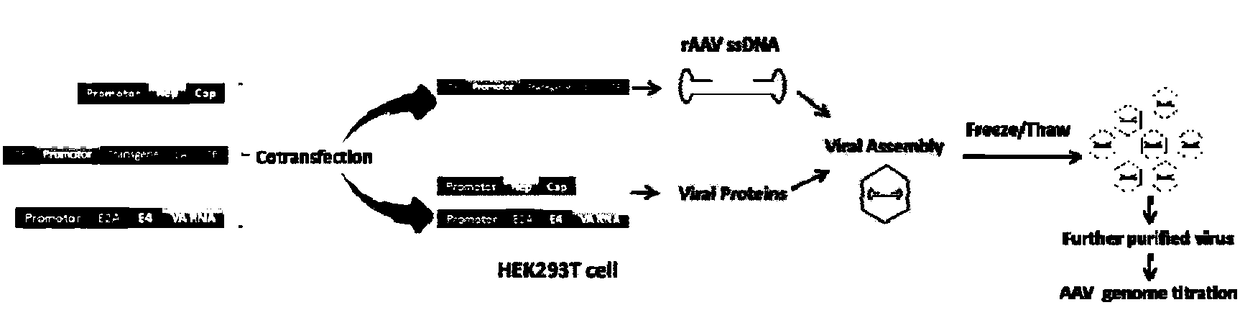

[0049] Such as image 3 Shown, the preparation method of a kind of rAAV vector particle in this implementation comprises the following steps:

[0050] (1) Culture of HEK293T cells:

[0051] Production of rAAV vector particles was performed in HEK293T. HEK293T cells were mixed at 1.4×10 per dish 6 The amount of cells was inoculated in a 10cm culture dish containing 15% (volume percent concentration) FBS DMEM medium, and placed at 37 ° C, 5% CO 2 cultured in an environment of saturated humidity. Transfection was performed 2 days after inoculation.

[0052] (2) Transfection of HEK293T cells:

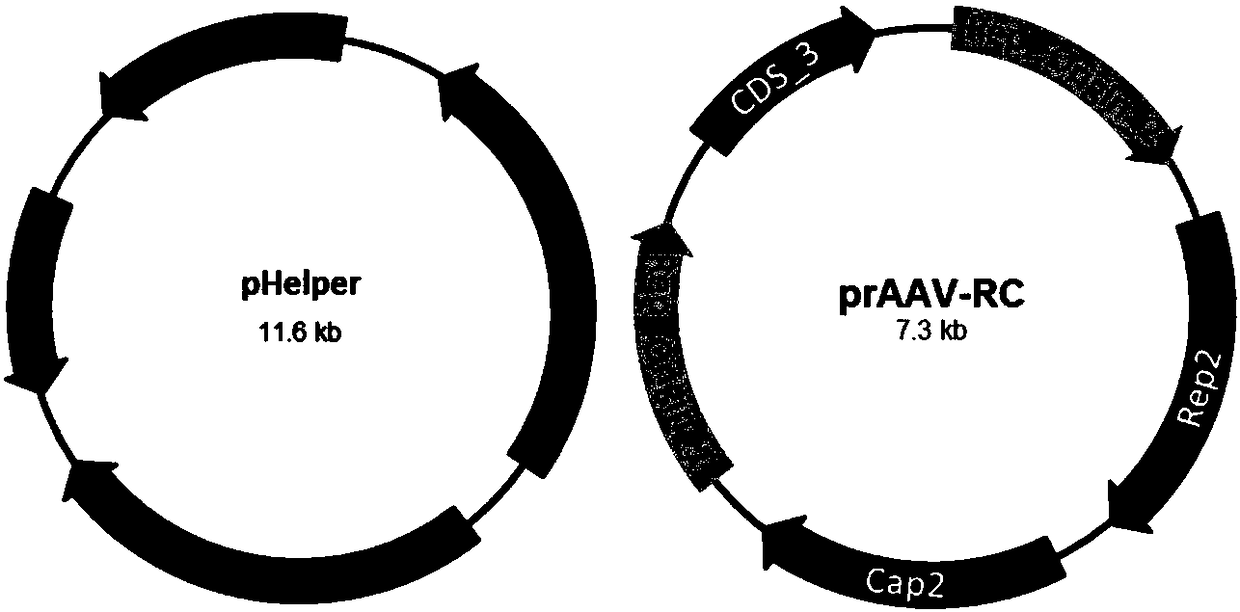

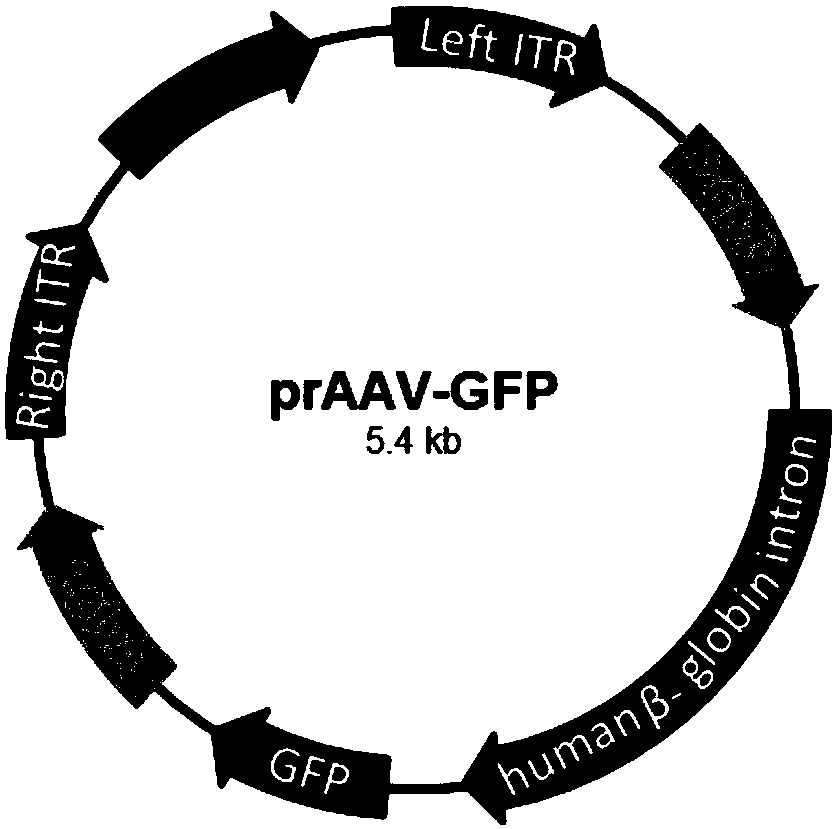

[0053] Before transfection, the cell culture medium was replaced with 5 ml of DMEM medium containing 5% (volume percent concentration) FBS. The two helper vector plasmids pHelper( Figure 1A ), prAAV-RC ( Figure 1A ) and a shuttle vector plasmid prAAV-GFP ( Figure 1B ) were co-transfected into HEK293T cells at a mass ratio of...

Embodiment 2

[0060] Example 2 Preparation of rAAV vector particles

[0061] Such as image 3 Shown, the preparation method of a kind of rAAV vector particle in this implementation comprises the following steps:

[0062] (5) Culture of HEK293T cells:

[0063] Production of rAAV vector particles was performed in HEK293T. HEK293T cells were mixed at 1.4×10 per dish 6 The amount of cells was inoculated in a 10 cm culture dish containing 8% (volume percent concentration) FBS DMEM medium, and placed at 37 ° C, 5% CO 2 cultured in an environment of saturated humidity. Transfection was performed 2 days after inoculation.

[0064] (6) Transfection of HEK293T cells:

[0065] Before transfection, the cell culture medium was replaced with 5 ml of DMEM medium containing 2% (volume percent concentration) FBS. The two helper vector plasmids pHelper( Figure 1A ), prAAV-RC ( Figure 1A ) and a shuttle vector plasmid prAAV-GFP ( Figure 1B ) were co-transfected into HEK293T cells at a mass ratio of...

Embodiment 3

[0072] Example 3 Preparation of rAAV vector particles

[0073] Such as image 3 Shown, the preparation method of a kind of rAAV vector particle in this implementation comprises the following steps:

[0074] (9) Culture of HEK293T cells:

[0075] Production of rAAV vector particles was performed in HEK293T. HEK293T cells were mixed at 1.4×10 per dish 6 The amount of cells was inoculated in a 10cm culture dish containing 20% (volume percent concentration) FBS DMEM medium, and placed at 37 ° C, 5% CO 2 cultured in an environment of saturated humidity. Transfection was performed 2 days after inoculation.

[0076] (10) Transfection of HEK293T cells:

[0077] Before transfection, the cell culture medium was replaced with 5 ml of DMEM medium containing 10% (volume percent concentration) FBS. The two helper vector plasmids pHelper( Figure 1A ), prAAV-RC ( Figure 1A ) and a shuttle vector plasmid prAAV-GFP ( Figure 1B ) were co-transfected into HEK293T cells at a mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com