Yeast extract liquid, preparation method, and application of same

A technology of yeast dipping and yeast dipping powder, applied in the field of biological products, can solve the problems of unstable quality, difficult concentration of production, contamination of miscellaneous bacteria, etc., to improve product yield and product quality, shorten the heating time of materials, reduce heat damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

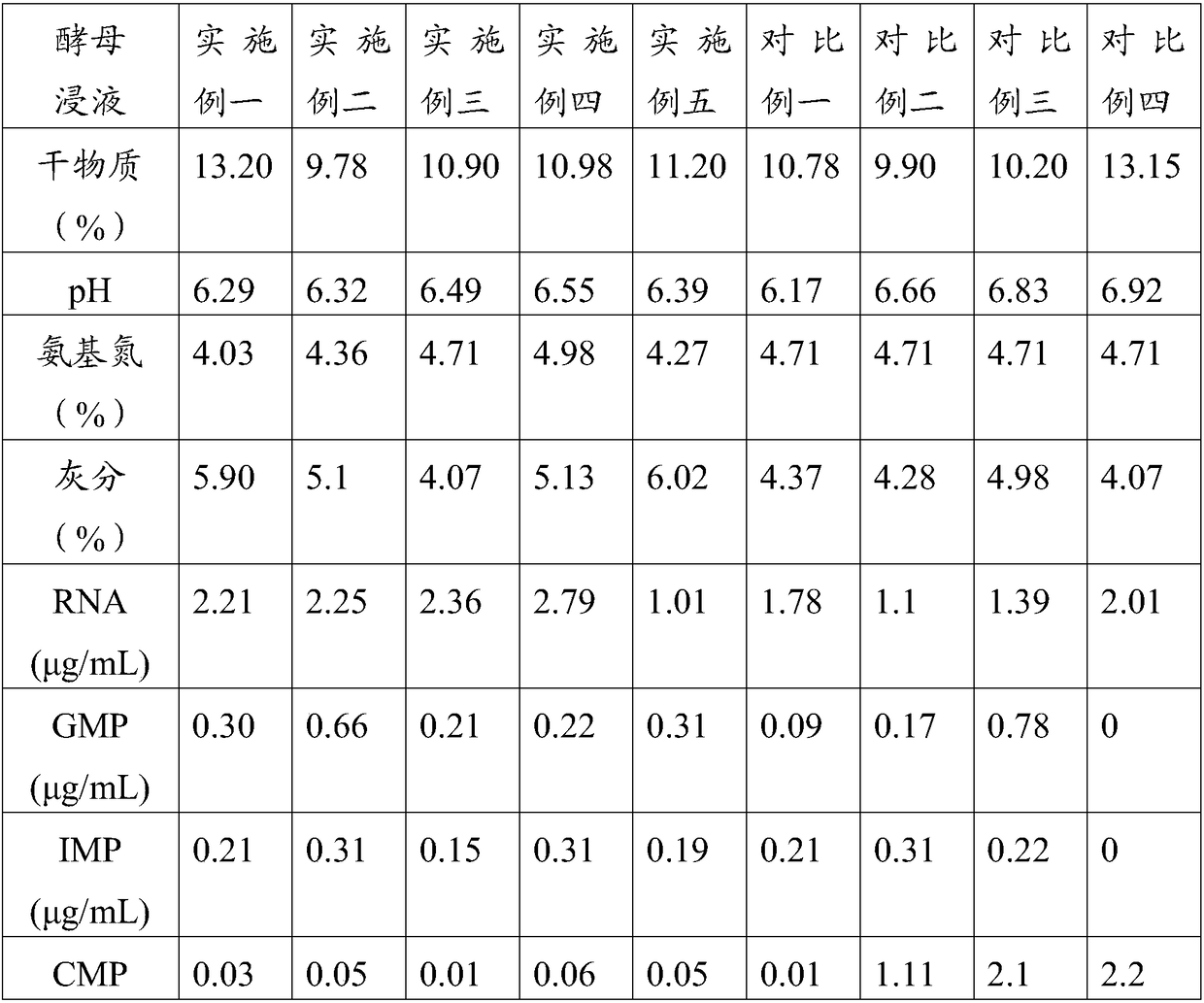

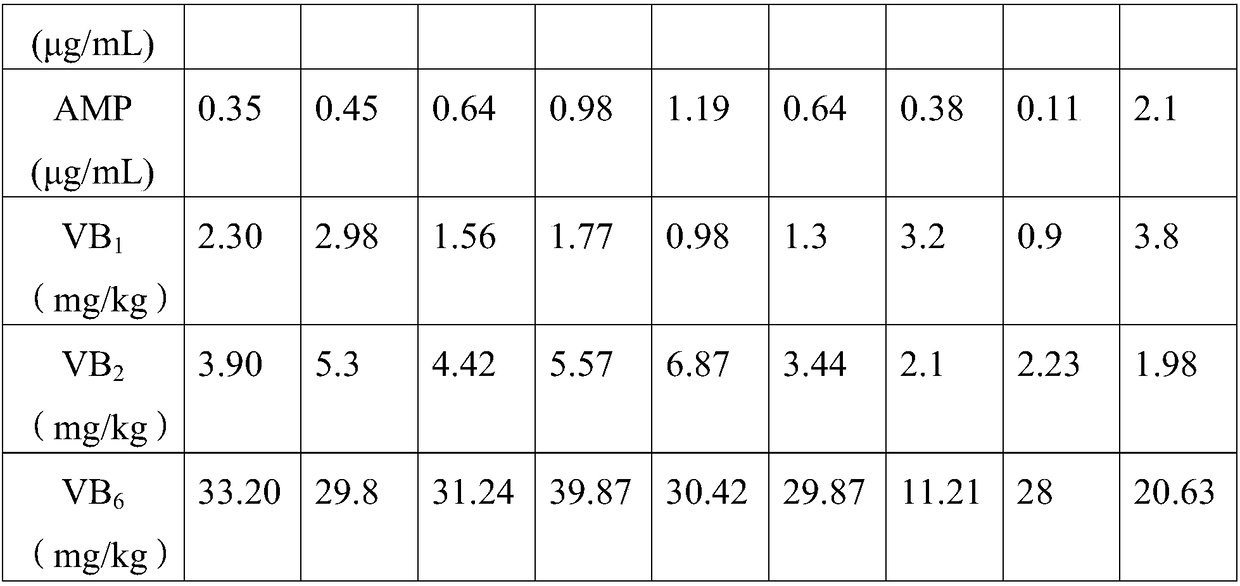

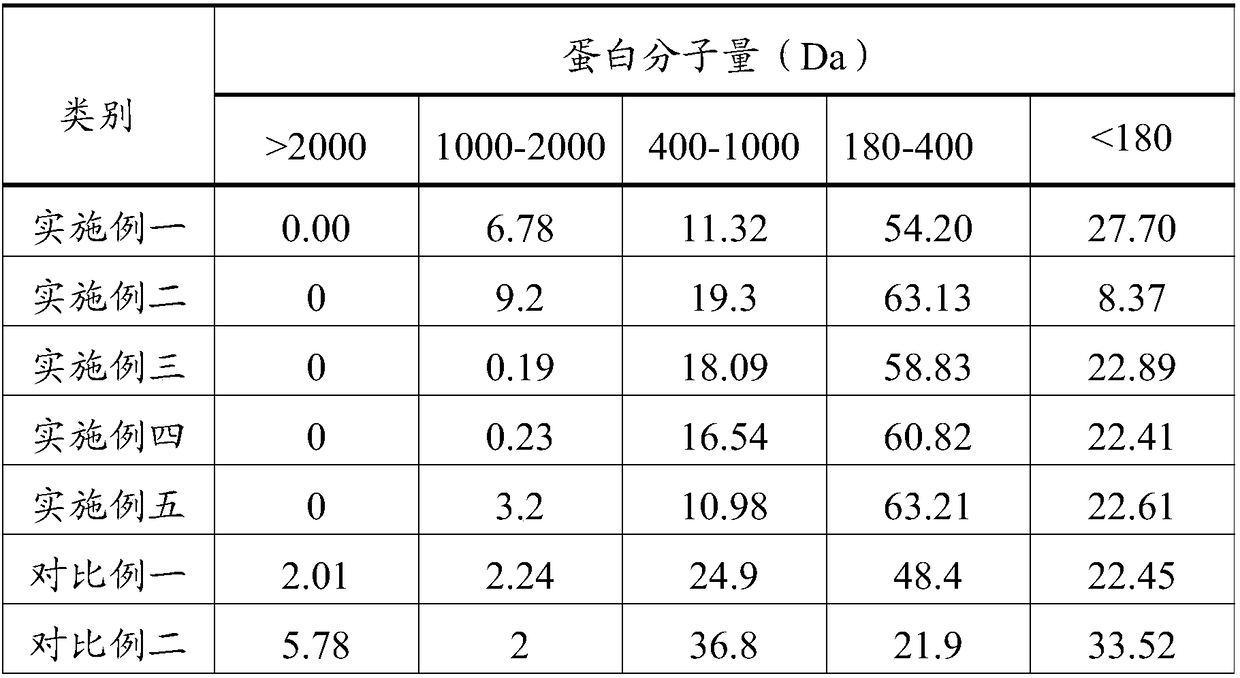

Examples

Embodiment 1

[0072] (1) Preparation method of yeast infusion

[0073] Embodiment 1 provides a method for preparing yeast infusion using vacuum and low temperature. Wherein, the yeast infusion is cultured at a high density using Saccharomyces cerevisiae until the wet weight of yeast cells is 220 g / L.

[0074] Among them, the method of cultivating yeast cells at high density is as follows:

[0075] a. Treatment of fermented raw materials: remove slag and precipitate molasses, add concentrated sulfuric acid to acidify to pH 2.0, and hydrolyze molasses to obtain fermented molasses with reducing sugar weight accounting for 20%; yeast extract powder is added with water to make a solution with a concentration of 20%; The molasses and yeast infusion solution was sterilized at 110°C for 10 minutes.

[0076] b. Seed culture: first-level seed culture, insert a ring of bacteria (Saccharomyces cerevisiae FX-2) into 200mL first-level medium from the slant of S. For seed culture, insert the seeds of t...

Embodiment 2

[0120] Embodiment 2 provides a method for preparing yeast infusion using vacuum and low temperature. Wherein, the yeast infusion is cultured at a high density using Saccharomyces cerevisiae until the wet weight of yeast cells is 280 g / L.

[0121] Among them, the method of cultivating yeast cells at high density is as follows:

[0122] a. Fermentation raw material treatment: molasses removes slag and precipitates, adds concentrated hydrochloric acid to acidify to pH2.5, hydrolyzes molasses to obtain fermented molasses with reducing sugar weight accounting for 25%, yeast extract powder is added with water to form a solution with a concentration of 25%; The molasses and yeast infusion solution was sterilized at 110°C for 10 minutes.

[0123] b. Seed culture: first-level seed culture, insert a ring of bacteria (Saccharomyces cerevisiae FX-2) into 200mL first-level medium from the slant of S. For seed culture, insert 1L of the secondary medium according to the inoculation amount ...

Embodiment 3

[0136] Embodiment 3 provides a method for preparing yeast infusion using vacuum and low temperature. Wherein, the yeast extract is cultured at a high density using Saccharomyces cerevisiae until the wet weight of yeast cells is 240 g / L.

[0137] Among them, the method of cultivating yeast cells at high density is as follows:

[0138] a. Fermentation raw material treatment: molasses deslagging and precipitation, adding concentrated nitric acid to acidify to pH 3.5, so that molasses is hydrolyzed to obtain fermented molasses with reducing sugar weight accounting for 22%, yeast extract powder is added with water to form a solution with a concentration of 22%; The molasses and yeast infusion solution was sterilized at 110°C for 10 minutes.

[0139] b. Seed culture: first-level seed culture, insert a ring of bacteria (Saccharomyces cerevisiae FX-2) from the strain storage slope into 250mL first-level medium, and cultivate at 32°C and 300rpm for 26h; second-level seed culture , ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com