Ultrahigh molecular weight polyethylene tube single screw extruder barrel forming method and the forming device thereof

An ultra-high molecular weight, single-screw extrusion technology, used in tubular articles, applications, household appliances, etc., can solve the problems of long plasticization time, low production efficiency, large finished products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the accompanying drawings.

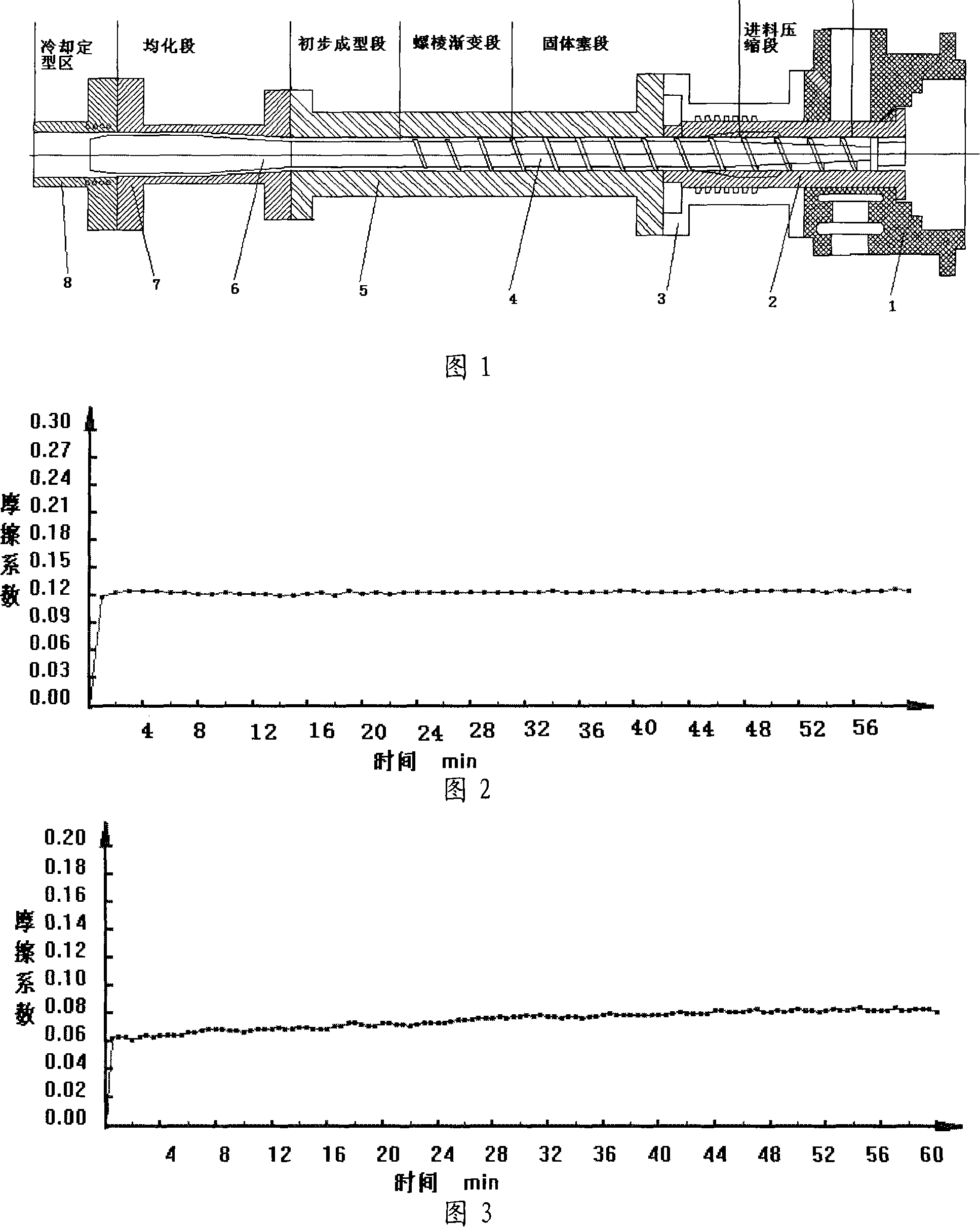

[0027] The forming equipment of the present invention comprises a hopper seat 1, a machine barrel, a screw 4, a shaping mandrel 6, a shaping sleeve 7 and a cooling jacket 8. The machine barrel is connected with the hopper seat 1 through a flange, and the machine barrel is composed of a front end barrel 5 and a rear end. The end barrel 3 is composed of a pressurized liner 2 in the rear end barrel, and a groove is opened on the liner 2 to ensure that the extruder generates sufficient extrusion pressure. The screw 4 is placed in the barrel and One end is fixed on the hopper seat, the other end of the screw 4 is connected with the shaped mandrel 6, and the front end barrel 5 is connected with the shaped sleeve 7 and the cooling jacket 8 in turn to form a whole. The shaping mandrel 6 and the screw rod 4 are separately manufactured and firmly connected.

[0028] The machine barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com