Method for producing graphite negative-electrode material by using needle coke, and negative-electrode material

A graphite negative electrode and needle coke technology, which is applied in chemical instruments and methods, battery electrodes, electrochemical generators, etc., can solve the problems of reduced high-rate discharge performance, low specific surface area, and high compaction density of negative graphite materials. High tap density, small specific surface area and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

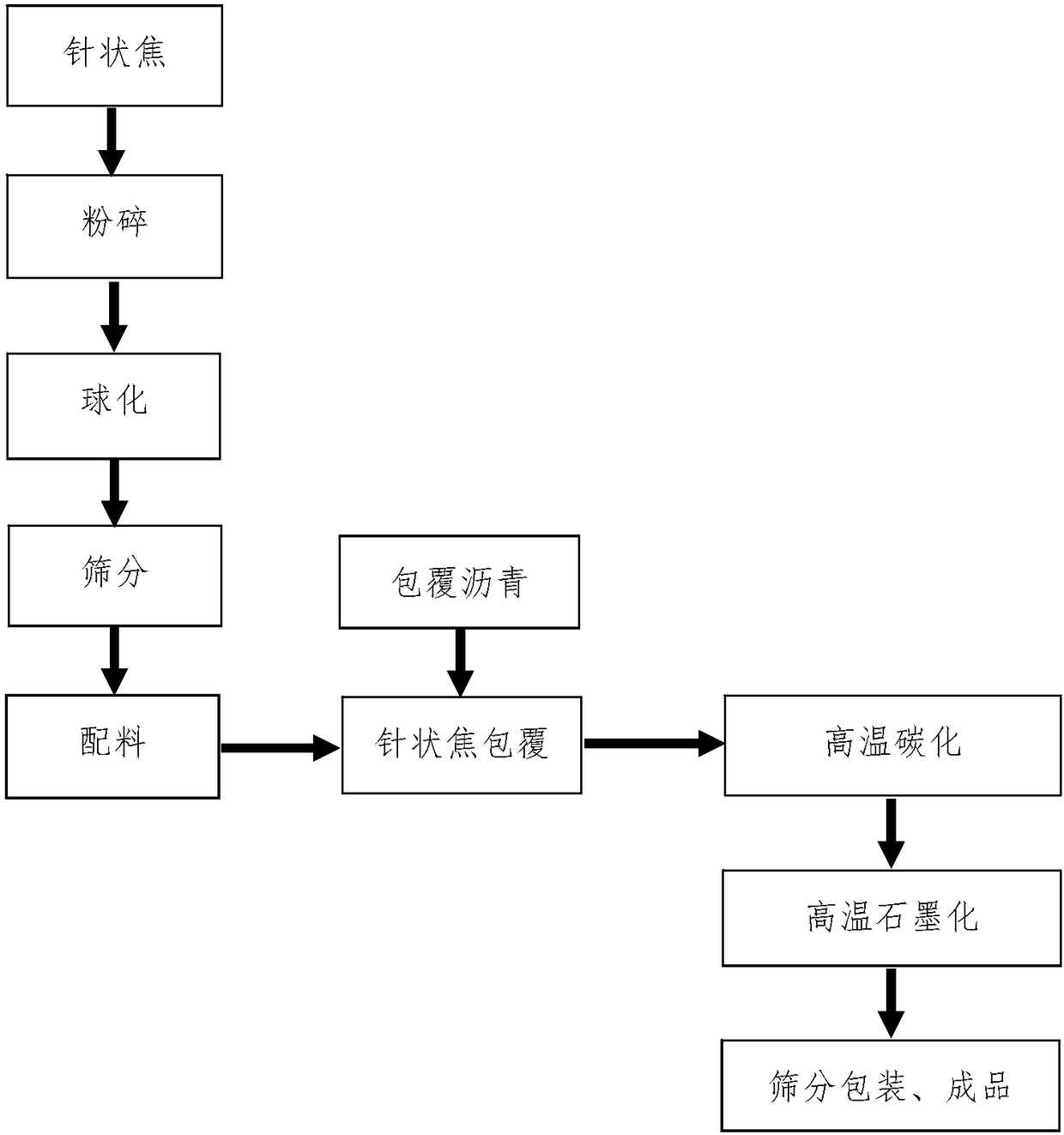

[0046] A method for utilizing needle coke to produce a graphite negative electrode material, comprising the following steps:

[0047] Pulverization: put the needle-shaped coke powder below 3mm into an airflow mill for pulverization, and pulverize it to a particle state of more than 10μm;

[0048] Spheroidization: The granular needle coke above 10μm is shaped by a crusher and ground into a spherical or ellipsoidal shape;

[0049] Screening: The spheroidized needle coke is screened by a crusher to obtain needle coke with a particle size of 10-15 μm, 15-25 μm and 25-30 μm, parts by weight: 13 parts for 10-15 μm, 15- 25μm is 52 parts, 25-30μm is 30 parts;

[0050] Ingredients: put the needle coke with a particle size of 10-15μm into the needle coke with a particle size of 15-25μm for mixing, mix evenly to get mixed powder A, then pour 1 / 3 parts by weight of the mixed powder A, after stirring evenly, finally pour the remaining mixed powder A into it for mixing;

[0051] Coating...

Embodiment 2

[0055] A method for utilizing needle coke to produce a graphite negative electrode material, comprising the following steps:

[0056] Pulverization: put the needle-shaped coke powder below 3mm into an airflow mill for pulverization, and pulverize it to a particle state of more than 10μm;

[0057] Spheroidization: The granular needle coke above 10μm is shaped by a crusher and ground into a spherical or ellipsoidal shape;

[0058] Screening: The spheroidized needle coke is screened by a crusher to obtain needle coke with a particle size of 10-15 μm, 15-25 μm and 25-30 μm, parts by weight: 10 parts for 10-15 μm, 15- 50 parts for 25μm, 20 parts for 25-30μm;

[0059] Ingredients: put the needle coke with a particle size of 10-15μm into the needle coke with a particle size of 15-25μm for mixing, mix evenly to get mixed powder A, then pour 1 / 3 parts by weight of the mixed powder A, after stirring evenly, finally pour the remaining mixed powder A into it for mixing;

[0060] Coati...

Embodiment 3

[0064] A method for utilizing needle coke to produce a graphite negative electrode material, comprising the following steps:

[0065] Pulverization: put the needle-shaped coke powder below 3mm into an airflow mill for pulverization, and pulverize it to a particle state of more than 10μm;

[0066] Spheroidization: The granular needle coke above 10μm is shaped by a crusher and ground into a spherical or ellipsoidal shape;

[0067] Screening: The spheroidized needle coke is screened by a crusher to obtain needle coke with a particle size of 10-15 μm, 15-25 μm and 25-30 μm, parts by weight: 15 parts for 10-15 μm, 15 parts for 15- 55 parts for 25μm, 35 parts for 25-30μm;

[0068] Ingredients: put the needle coke with a particle size of 10-15μm into the needle coke with a particle size of 15-25μm for mixing, mix evenly to get mixed powder A, then pour 1 / 2 parts by weight of the mixed powder A, after stirring evenly, finally pour the remaining mixed powder A into it for mixing;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com