Multifunctional testing device and method for asphalt stirring, preparation and microwave aging

An asphalt mixing and testing device technology, applied in the field of asphalt mixing and asphalt aging testing devices, can solve the problems of reducing the service performance and life of asphalt and asphalt concrete, low aging efficiency, and hardening of asphalt, etc., so as to improve the preparation efficiency and output. , reduce the effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

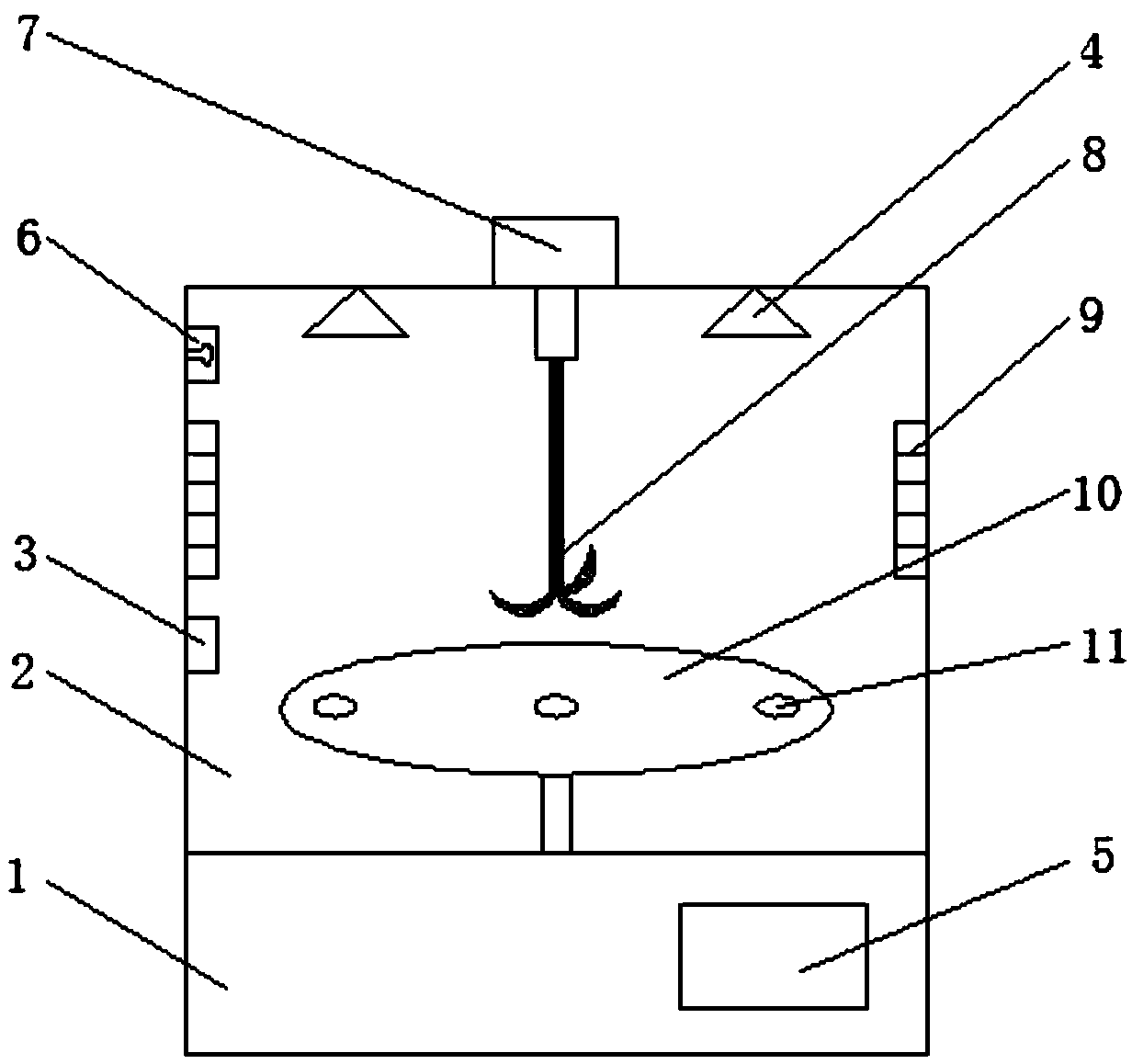

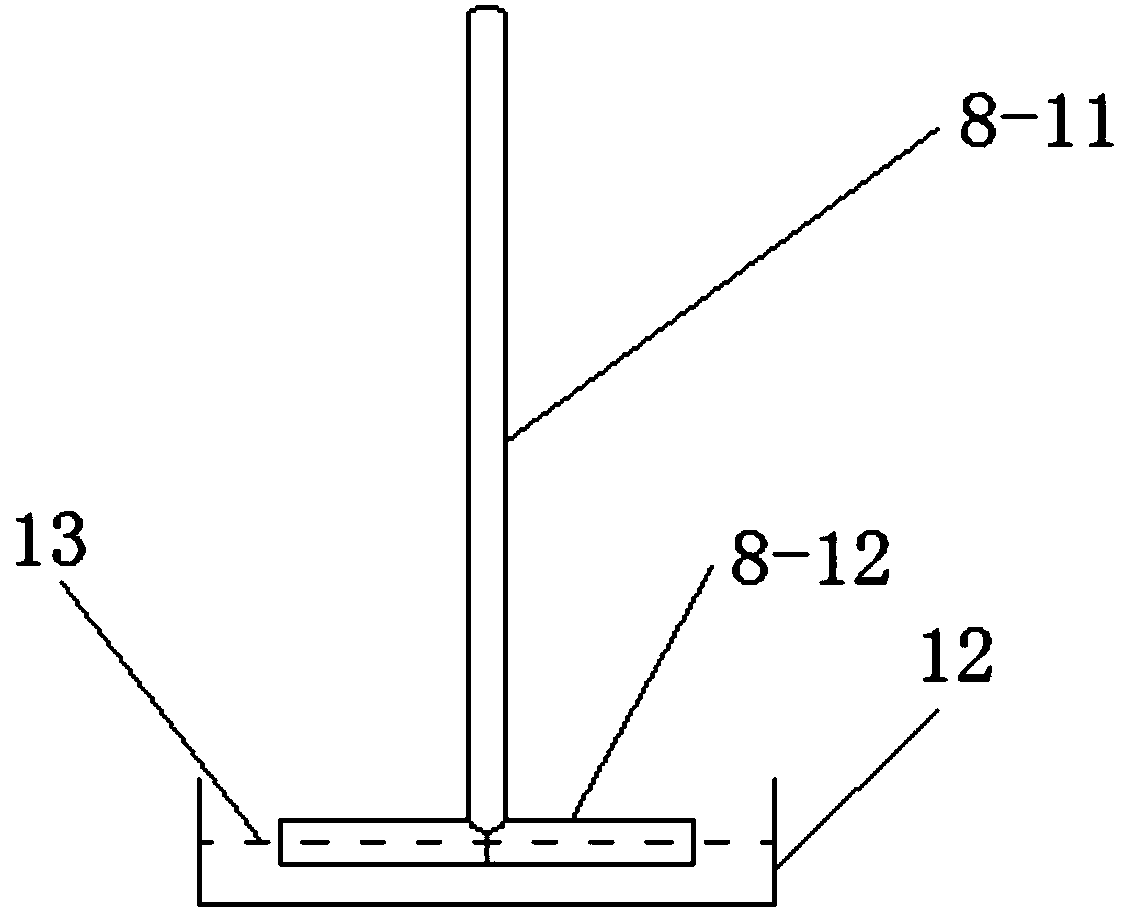

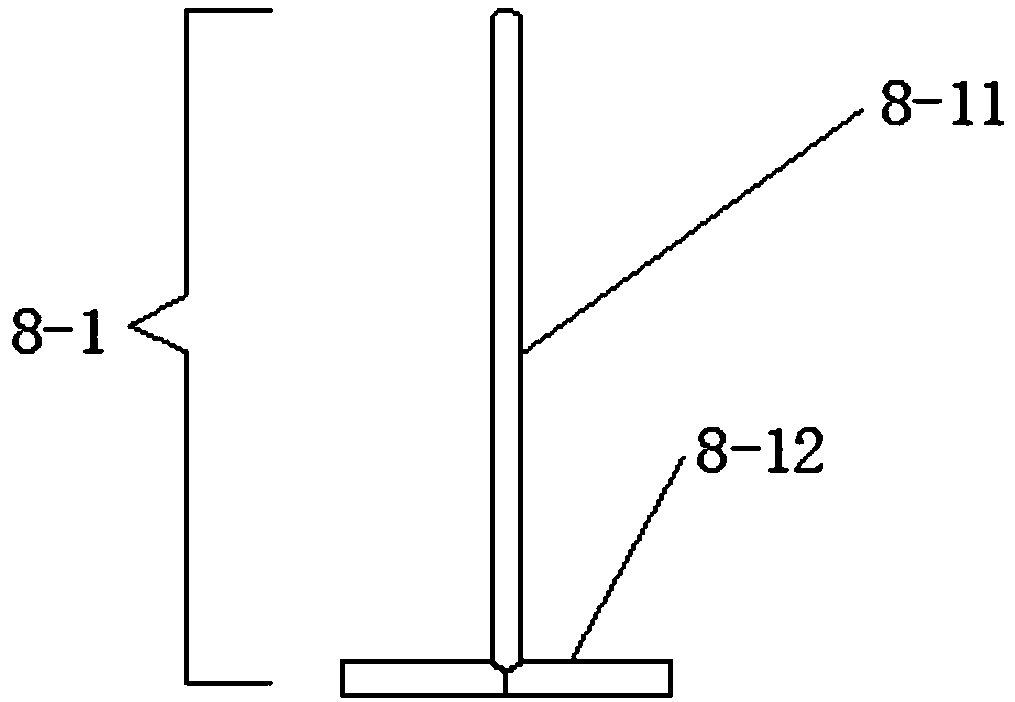

[0025] like Figure 1-4 As shown, the present invention provides a multifunctional test device for asphalt mixing, preparation and microwave aging, including: temperature control system, stirring system, loading platform 10 and blast system; temperature control system includes control box 1, environment box 2. Infrared temperature probe 3, microwave generator 4 and control panel 5, the mixing system includes lighting 6, motor 7 and rotor 8; rotor 8 includes No. 1 rotor 8-1 and No. 2 rotor 8-2, and the blast system includes Blower window 9, fan, filter, heater and cooler, fan, filter, heater and cooler are arranged in the inside of control box 1;

[0026] The upper part of the control box 1 is equipped with an environmental box 2, the front side of the control box 1 is equipped with a control panel 5, and the top of the environmental box 2 is equipped with a motor 7, the output shaft of the motor 7 runs through the environmental box 2 and is connected to the rotor through a cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com