Treatment method of cyanide-containing electroplating waste water

A treatment method and technology for cyanide wastewater, which is applied in metallurgical wastewater treatment, multi-stage water treatment, degassed water/sewage treatment, etc., to achieve the effect of improving the stripping effect, increasing the removal rate, and reducing the effect of insoluble highly toxic cuprous cyanide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

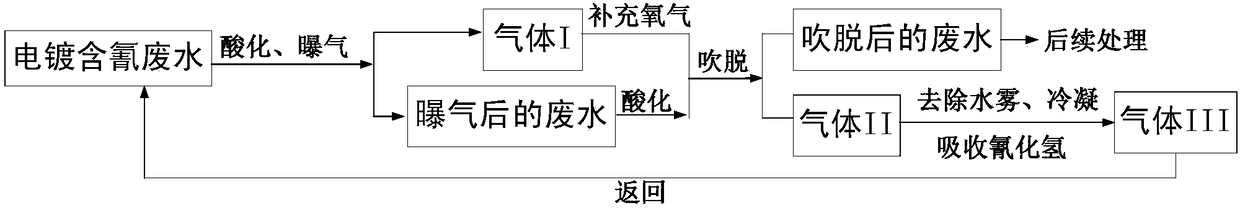

[0051] A treatment method for electroplating cyanide-containing wastewater, comprising the steps of:

[0052] (1) Isolate the electroplating cyanide-containing wastewater from the outside air, add dilute sulfuric acid for acidification treatment until the pH value is 4, convert the carbonate and bicarbonate in the electroplating cyanide-containing wastewater into carbonic acid, and then expose it by pressurization Gas, supplemented by stirring in the process of aeration, the diameter of the bubble is 0.1mm, the gas-liquid ratio is 1:100, and the volume percentage of carbon dioxide obtained is 80% gas I;

[0053] (2) Under the condition of isolating the air, add dilute sulfuric acid to the electroplating cyanide-containing wastewater to continue the acidification treatment until the pH is 1, then make the volume percentage of oxygen in the mixed gas be 0.1% after supplementing oxygen in the gas I, and use It performs gas-liquid countercurrent contact stripping in a stripping to...

Embodiment 2

[0056] A treatment method for electroplating cyanide-containing wastewater, such as figure 1 shown, including the following steps:

[0057] (1) Isolate the electroplating cyanide-containing wastewater from the outside air, add dilute sulfuric acid for acidification treatment until the pH value is 5, convert the carbonate and bicarbonate in the electroplating cyanide-containing wastewater into carbonic acid, and then expose it by pressurization Gas, supplemented by stirring in the process of aeration, the diameter of the bubbles is 6mm, the gas-liquid ratio is 1:300, and the volume percentage of carbon dioxide obtained is 65% gas I;

[0058] (2) Under the condition of isolating the air, adding dilute sulfuric acid to the electroplating cyanide-containing wastewater to continue the acidification treatment until the pH is 1, after supplementing oxygen in the gas I, the volume percentage of oxygen in the mixed gas is 15%. Gas-liquid countercurrent contact stripping is carried out...

Embodiment 3

[0062] A treatment method for electroplating cyanide-containing wastewater, comprising the steps of:

[0063] (1) Isolate the cyanide-containing wastewater in the open plating tank from the outside air in the cyanide-containing electroplating process, add dilute sulfuric acid for acidification treatment to a pH value of 3, and convert the carbonate and bicarbonate in the electroplating cyanide-containing wastewater It is carbonic acid, then aerated by pressurization, supplemented by stirring in the process of aeration, the diameter of the bubble is 1mm, the gas-liquid ratio is 1:150, and the volume percentage of carbon dioxide obtained is 70% gas I;

[0064] (2) Under the condition of isolating the air, adding dilute sulfuric acid to the electroplating cyanide-containing waste water and carrying out acidification treatment to pH is 3, and after supplementing oxygen in the gas I, the volume percentage of oxygen in the mixed gas is 6%. Gas-liquid countercurrent contact stripping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com