Ectopic remediation process for VOCs/SVOCs contaminated soil

A technology for polluted soil and ex-situ remediation, applied in the field of environmental engineering, can solve the problems of lack of relatively perfect remediation process, immature development of treatment technology, etc., and achieve the effect of efficient remediation, improved air lift effect, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

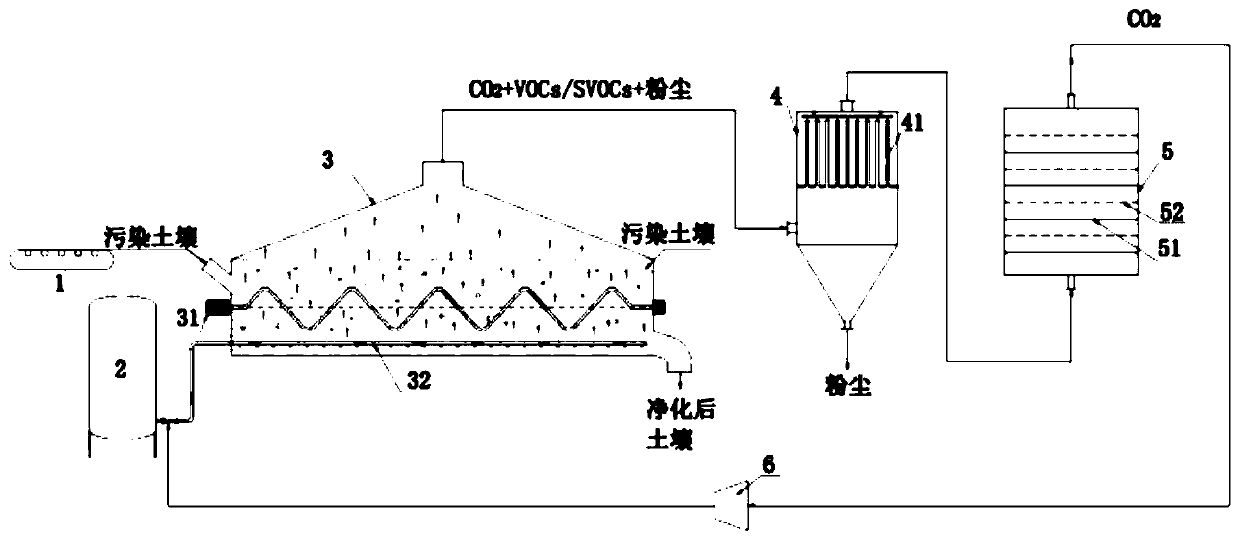

[0021] refer to figure 1 , an ex-situ remediation process for VOCs / SVOCs contaminated soil, comprising the following steps:

[0022] In the first step, the polluted soil (concentration of VOCs / SVOCs is 2100-2600mg / kg) that has been mechanically pulverized with a particle size of no more than 2 mesh VOCs / SVOCs is passed through the conveyor belt 1 at a distance of 5m. 3 The speed of / h is sent in the rotary gas stripping furnace 3, then evenly distributed in the furnace cavity of the rotary gas stripping furnace 3 under the agitation of the screw propeller 31 in the rotary gas stripping furnace 3;

[0023] The screw propeller 31 in the rotary gas stripping furnace 3 is driven by a motor to continuously rotate, and the inclination angle of the rotary gas stripping furnace 3 is set to 15°, so that the purified soil can flow out from the rotary gas stripping furnace 3;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com