A kind of air lifting mud suction device and its application

A technology of air lift and mud suction pipe, which is applied to the feeding/discharging device of the sedimentation tank, etc., can solve the problem that the normal sludge discharge of the coagulation sedimentation tank cannot be realized, the sludge at the bottom of the pool is not easy to be pumped up, and the air lift effect is poor, etc. problem, to achieve good operation effect, improve mud-water separation effect, and improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention can be further clearly understood through the specific examples of the present invention given below, but they are not intended to limit the present invention. Parts that are not described in detail in the detailed description are obtained by using existing technologies, known technical means and industry standards.

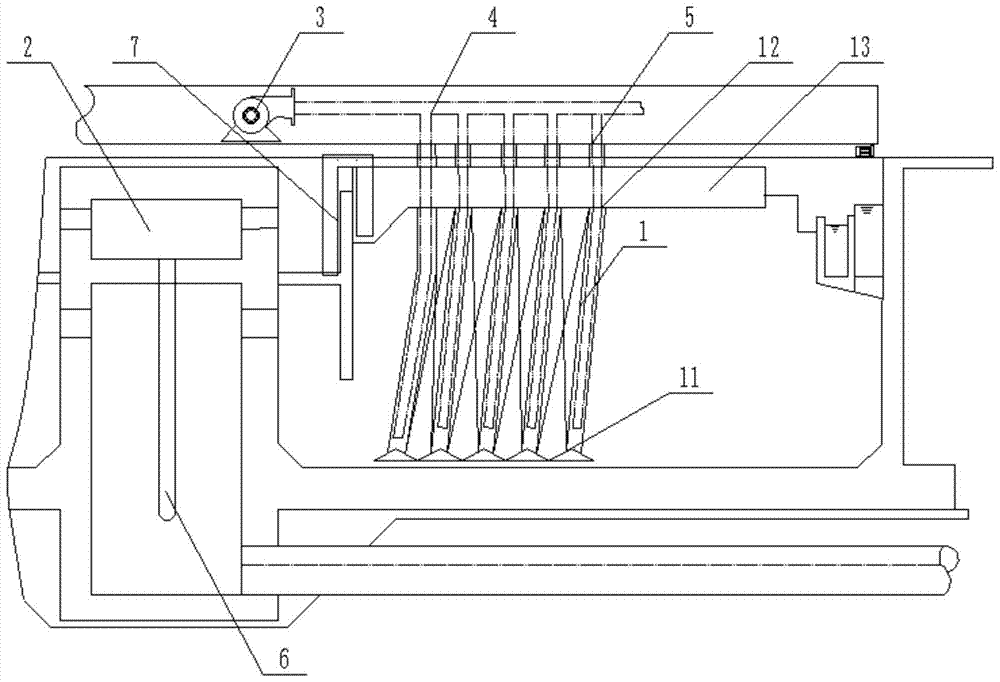

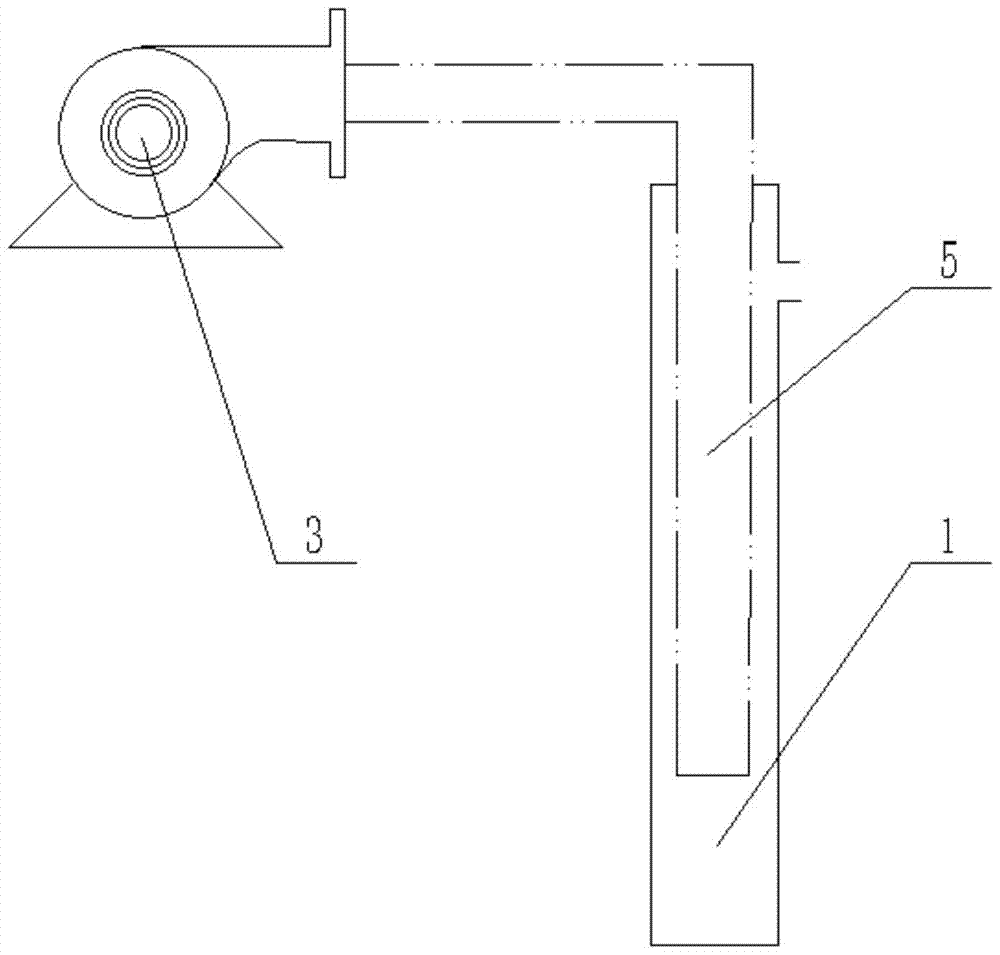

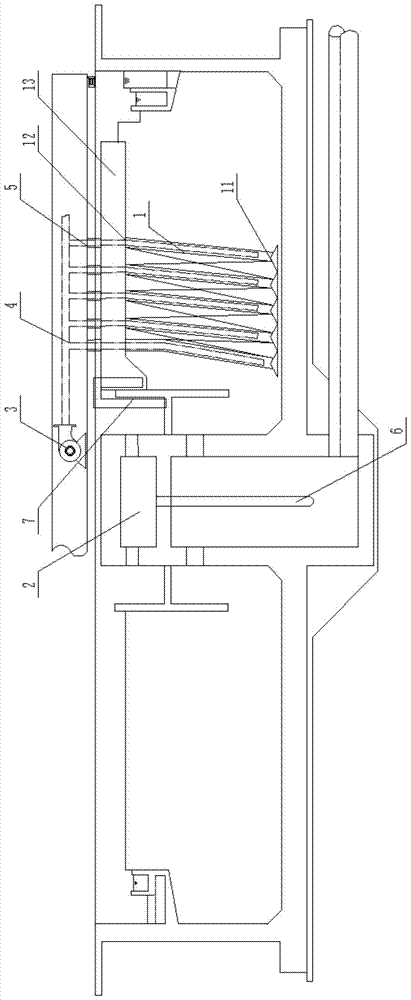

[0034] Please refer to the attached Figures 1 to 2 , the airlift mud suction device of the present invention can be applied to the coagulation sedimentation tank scraper suction mud machine, including

[0035] Five suction pipes 1,

[0036] The mud collecting tank 13 is connected with five mud suction pipes 1, and is used to concentrate the sludge transported by the mud suction pipe 1;

[0037] Mud barrel 2, used to concentrate sludge;

[0038] Blower 3;

[0039] Air pipe 4; connected with blower 3, used to deliver compressed air;

[0040] Five air pipes 5 are connected to the air pipe 4; each air pipe 5 is inserted into the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com