Air lift separator

A separator and air stripping technology, applied in the field of final product separation and air stripping process, can solve the problems of complex and unsafe operation process, easy occurrence of bias flow, channel flow, easy occurrence of gas phase entrainment, etc., to achieve simple and safe operation, easy liquid Bit detection, the effect of enhanced sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

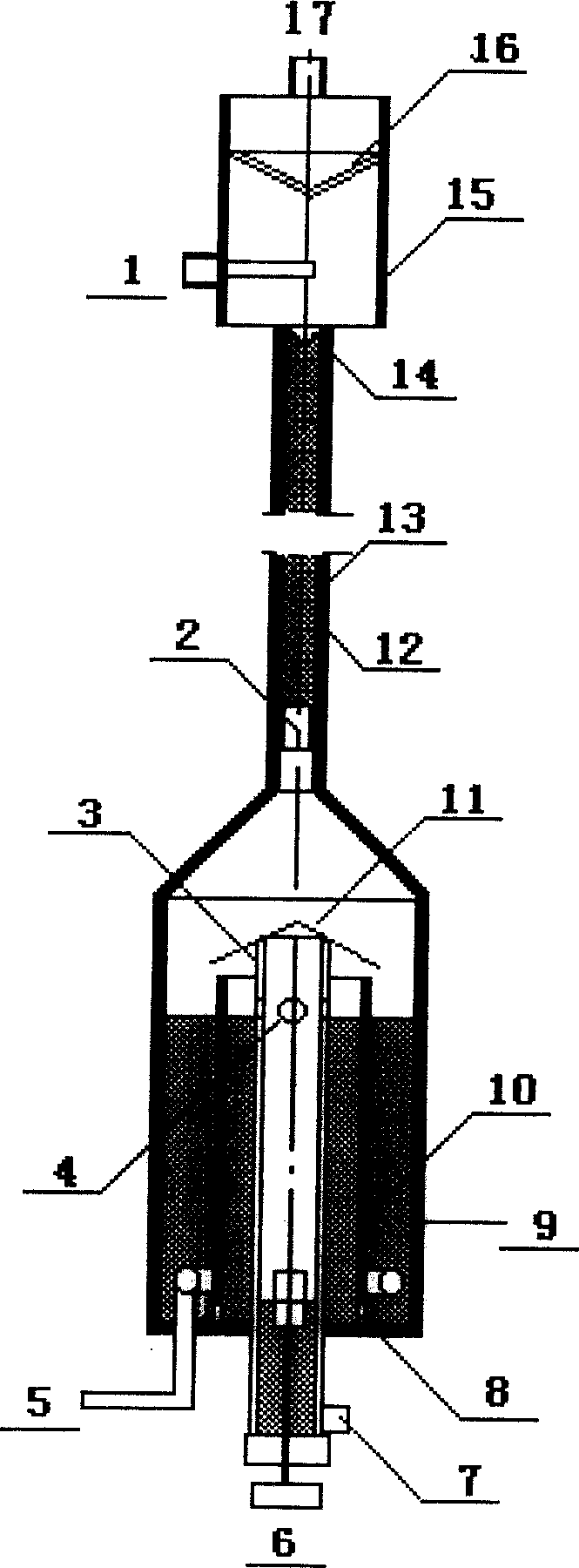

[0011] The structure and operation method of the air stripping separator of the present invention will be further described below in conjunction with the accompanying drawings.

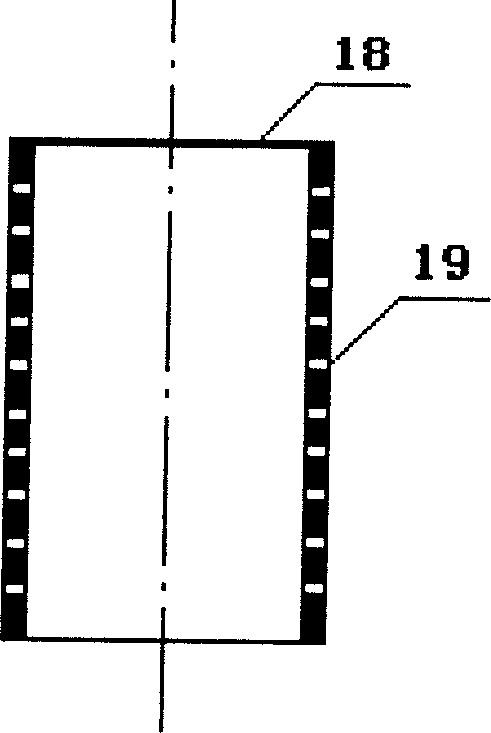

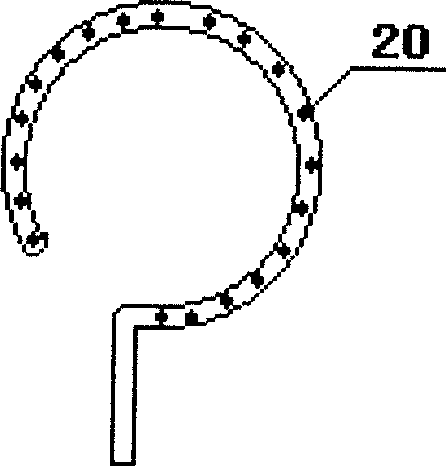

[0012] Such as figure 1 As shown, the structural composition and working process of the oil discharge mechanism at the bottom of the air lift separator of the present invention are as follows: the oil discharge pipe 3 and the diversion sleeve 10 are respectively placed in the liquid collector 9 from the inside to the outside, and the upper part of the oil discharge pipe 3 is installed with a flow guide Cover 11, the lower part of the diversion sleeve 10 is provided with a number of bottom holes 8, the upper part of the oil discharge pipe 3 is provided with a plurality of diversion holes 4, the lower part is provided with an oil outlet 7 and a liquid level detector 6 is installed. 9 and the lower part between the guide sleeve 10 is arranged an annular blowing pipe 5 .

[0013] When the liquid flowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com