Magnesium-aluminum double-layer composite barrel-shaped part and staggered-distance spin forming process thereof

A double-layer composite and staggered-pitch spinning technology is applied in the field of forming and spinning of composite cylindrical parts, which can solve the problems of difficult plastic deformation and corrosion resistance of magnesium alloys, and achieve improved plasticity and corrosion resistance, easy forming, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

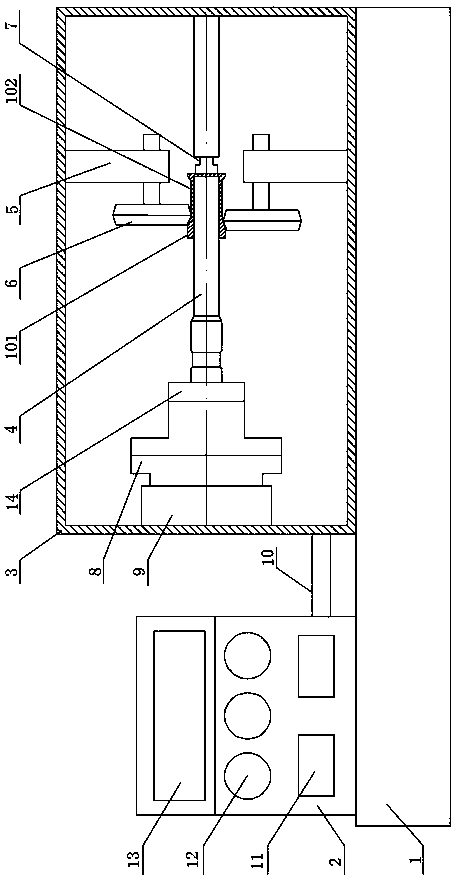

[0030] This embodiment provides a staggered-pitch spinning forming process for a magnesium-aluminum double-layer composite cylindrical part, which includes grinding and cleaning the aluminum alloy outer cylinder and magnesium alloy inner cylinder obtained by machining, and then performing staggered-pitch spinning, The specific implementation process of staggered spinning is as follows:

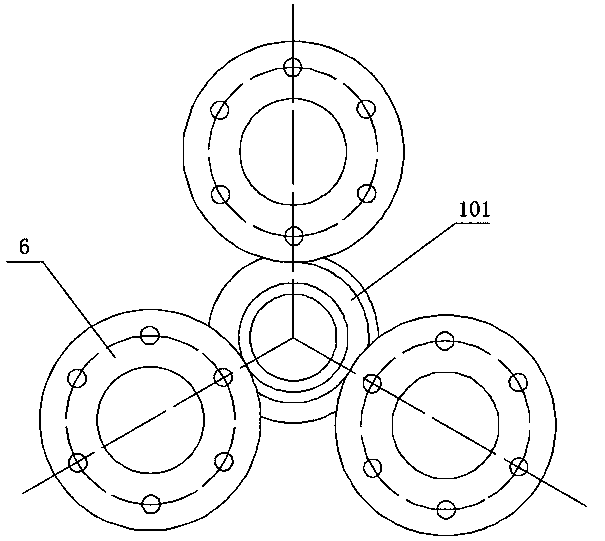

[0031] S1, heat the aluminum alloy outer cylinder and the magnesium alloy inner cylinder to 390°C and keep it warm for 10 minutes, heat the spinning spindle 4 and the rotary wheel 6 of the three-spinning wheel spinning machine to 200±10°C;

[0032] S2, the magnesium alloy inner cylinder is sleeved on the spinning spindle 4, the aluminum alloy outer cylinder is sleeved outside the magnesium alloy inner cylinder, and the spinning is carried out by using the three-wheel staggered forward rotation method, and the rotation speed of the spinning spindle 4 is 600r / min , the feed speed of the rotary w...

Embodiment 2

[0044] This embodiment provides a magnesium-aluminum double-layer composite cylindrical part, which is made according to the staggered spinning process of the magnesium-aluminum double-layer composite cylindrical part described in Embodiment 1, including an aluminum alloy outer cylinder and an aluminum alloy outer cylinder. Magnesium alloy inner barrel inside the barrel.

[0045] The composite cylindrical part uses aluminum alloy as the outer layer material to improve the corrosion resistance of the cylindrical part while maintaining its great advantage of light weight; the overall thinning rate is 65%; there are no spinning cracks and wrinkles on the inner and outer surfaces And macroscopic defects such as peeling appear; through the observation and analysis of the microstructure of the bonding interface with a metallographic microscope and a scanning electron microscope, it is found that the two interfaces are well bonded; according to the nano-indentation curve, it can be co...

Embodiment 3

[0047] This embodiment takes AZ31 magnesium alloy plate and 2024Al aluminum alloy plate as examples to further illustrate the staggered pitch spinning process of the magnesium-aluminum double-layer composite cylindrical part described in embodiment 1 and the magnesium-aluminum double-layer described in embodiment 2. Composite barrel. The size of the AZ31 magnesium alloy plate is 300mm×300mm×25mm, and the size of the 024Al aluminum alloy plate is 300mm×300mm×30mm.

[0048] The staggered spinning forming process of magnesium-aluminum double-layer composite cylindrical parts is as follows.

[0049] (1) Machining

[0050] The machining process of aluminum alloy outer cylinder and magnesium alloy inner cylinder is: blanking - rough turning - semi-finishing turning - calibration - finishing turning, the specific implementation process is:

[0051] S1, cutting cylindrical blanks with a wire cutting machine on the magnesium alloy plate and the aluminum alloy plate;

[0052] S2, use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Bore diameter | aaaaa | aaaaa |

| Outer circle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com