A kind of antibacterial and anti-protein adhesion coating and preparation method thereof

An anti-protein and coating technology, applied in the direction of coating, etc., can solve the problems of limiting antibacterial coatings, and achieve the effects of inhibiting reproduction, good biocompatibility, and inhibiting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

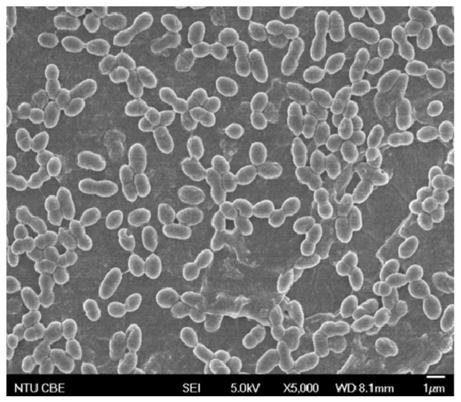

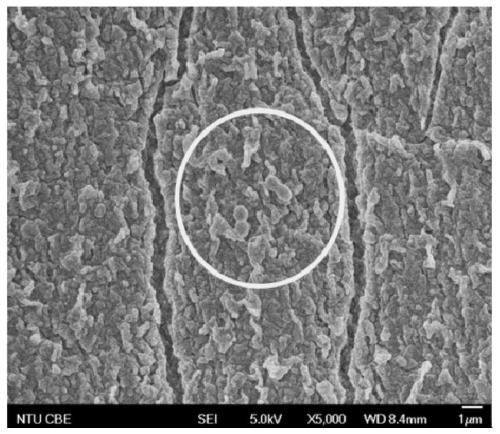

Image

Examples

Embodiment 1

[0030] In the present embodiment, the preparation method of antibacterial and anti-protein adhesion coating comprises the steps:

[0031] S1. Add 4g of allyl imidazole and 0.004g of ammonium persulfate into 20mL of ethanol, heat to 80°C, react for 2h, precipitate the reactant with acetone, separate and vacuum dry to obtain polyimidazole;

[0032] S2. Take 2g of the polyimidazole prepared in S1 and 0.2g of allyl iodide and add it to 10mL of methanol, then add 0.002g of 2,6-di-tert-butylphenol, react at 40°C for 48h, and precipitate the reactant with ether , separated and vacuum-dried to obtain polyimidazolium salt;

[0033] S3. Put the 0.1mm thick polypropylene film into the plasma implanter, bombard the surface of the material with argon plasma for 0.5h, and carry out activation treatment; then the polypropylene film is immersed in the structure unit containing 1g polyimidazolium salt and 0.1g anti-protein adhesion The solution is subjected to microwave treatment for 0.1 h, ...

Embodiment 2

[0037] In the present embodiment, the preparation method of antibacterial and anti-protein adhesion coating comprises the steps:

[0038] S1. Add 4g allyl imidazole, 4g vinyl imidazole and 0.8g benzoyl peroxide to 40mL ethanol, use a 30w ultraviolet lamp to irradiate, react for 2h, precipitate the reactant with acetone, separate and vacuum dry to obtain poly imidazole;

[0039] S2. Take 2g of the polyimidazole prepared in S1 and 4g of allyl iodide and add it to 20mL of methanol, then add 0.4g of 2,6-di-tert-butylphenol, react at 70°C for 2h, and precipitate the reactant with ether. Separation and vacuum drying to obtain polyimidazolium salt;

[0040] S3, put the 0.1mm thick polyethylene film into the plasma implanter, bombard the surface of the material with oxygen plasma for 0.5h, and carry out activation treatment; then the polyethylene film is immersed in the structure unit containing 1g polyimidazolium salt and 2g anti-protein adhesion solution, heated to 60°C for 12 ho...

Embodiment 3

[0044] In the present embodiment, the preparation method of antibacterial and anti-protein adhesion coating comprises the steps:

[0045] S1. Add 8g of allyl imidazole and 0.2g of potassium persulfate to 40mL of ethanol, heat to 70°C in microwave, react for 2h, precipitate the reactant with acetone, separate and vacuum dry to obtain polyimidazole;

[0046] S2. Take 4g of the polyimidazole prepared in S1 and 8g of allyl iodide and add it to 40mL of methanol, then add 0.08g of 2,6-di-tert-butylphenol, react at 70°C for 48h, and precipitate the reactant with ether. Separation and vacuum drying to obtain polyimidazolium salt;

[0047] S3. Put a 1mm thick silicon rubber sheet into a plasma implanter, bombard the surface of the material with helium plasma for 1 hour, and perform activation treatment; then immerse the silicon rubber sheet into a structure unit containing 2g of polyimidazolium salt and 2g of anti-protein adhesion The solution was heated to 60°C for 12 hours, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com