Ferromagnetic catalyst for treating nitric oxides in exhaust gas through selective catalytic reduction reaction and method thereof

A technology of ferrite magnets and nitrogen oxides, which is applied in the field of ferrite magnet catalyst and its field for selective catalytic reduction reaction to treat nitrogen oxides in exhaust gas, can solve the problems of high reaction temperature of SCR catalyst and narrow effective treatment temperature range, etc. To achieve the effect of reducing the starting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to fully understand the present invention, preferred embodiments are exemplified below and described in detail with the accompanying drawings, which are not intended to limit the present invention.

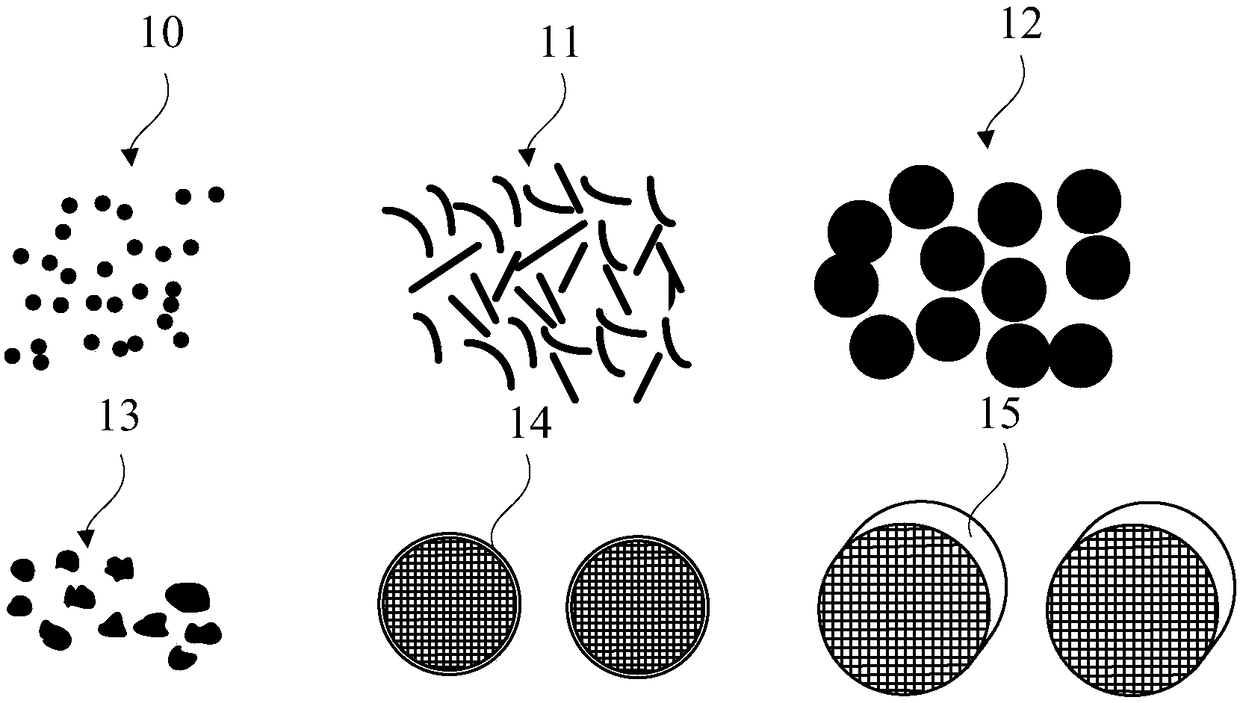

[0041] The ferrite magnet catalyst material, its treatment system and its treatment method for treating exhaust gas nitrogen oxides with selective catalytic reduction reaction in a preferred embodiment of the present invention are suitable for use in various exhaust emission treatment equipment, for example: especially suitable for use in automobiles Engine combustion (for example: diesel engine), industrial combustion (for example: boiler system), waste gas treatment in waste incineration treatment industry, petrochemical industry, metal smelting industry, but it is not intended to limit the present invention.

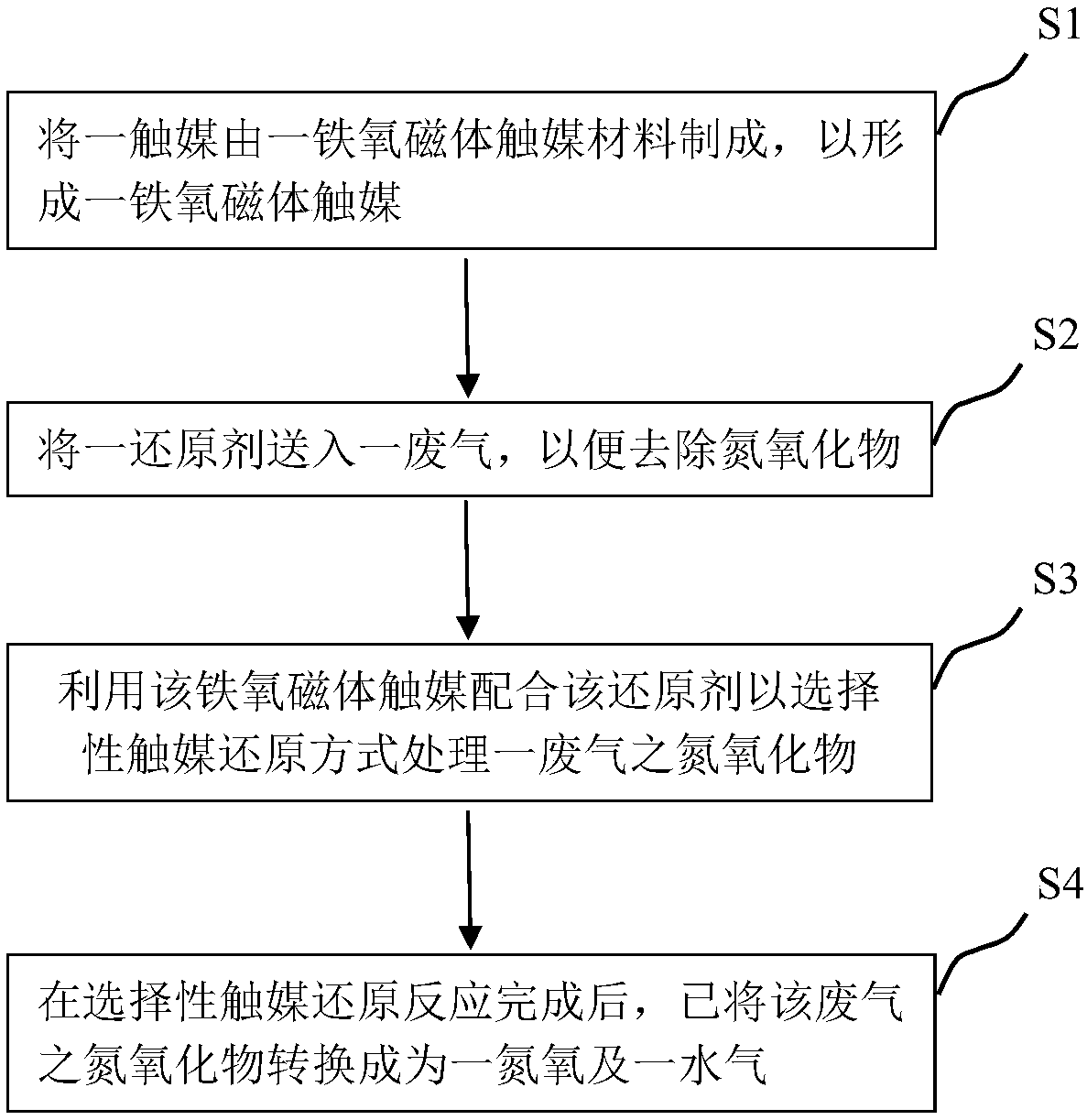

[0042] figure 1 A schematic flow chart of a method for treating nitrogen oxides in exhaust gas by selective catalytic reduction reaction according to a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com