A method for preparing fibers by adding recycled materials of waste non-woven fabrics

A non-woven fabric, recycled material technology, applied in fiber processing, textile and papermaking, complete sets of equipment for the production of artificial threads, etc. Polymer molecular weight distribution and other problems, to achieve the effect of energy saving and environmental protection production process, reducing labor and material consumption, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In this embodiment, recycled waste PP / PE nonwoven fabrics or scraps generated during the production process of PP / PE nonwoven fabrics are used as raw materials, and the recycled melt of waste materials is obtained through the steps of regeneration treatment.

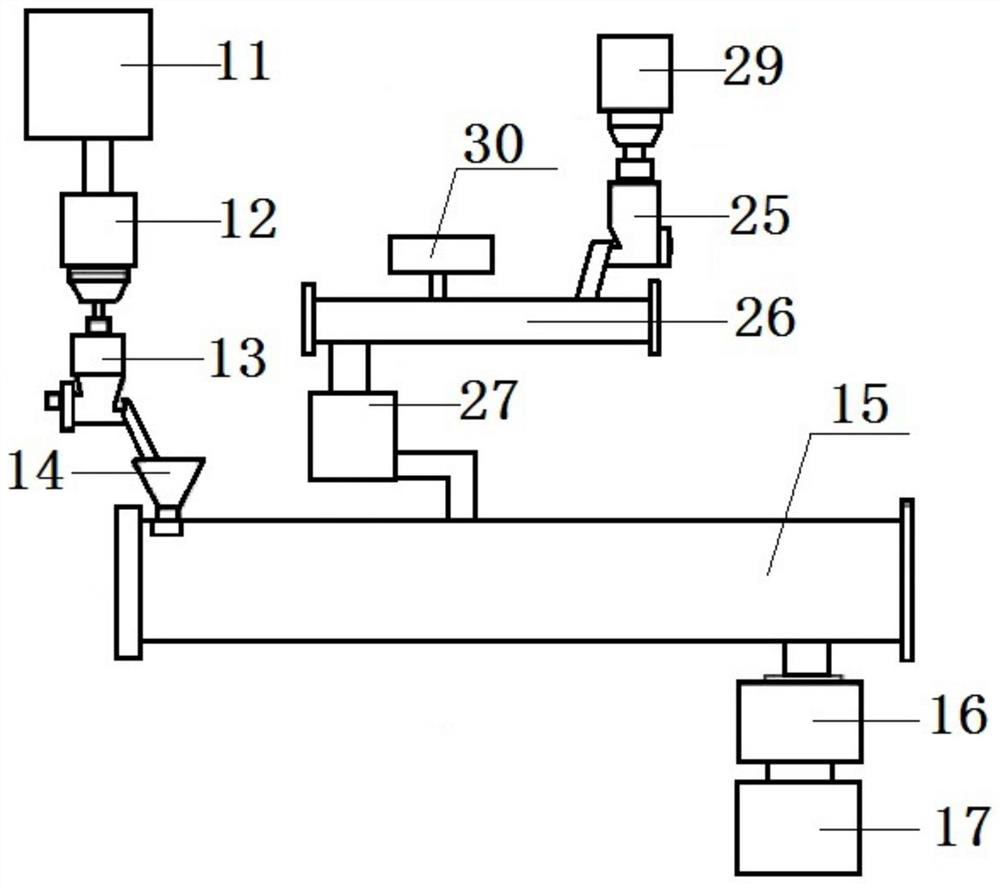

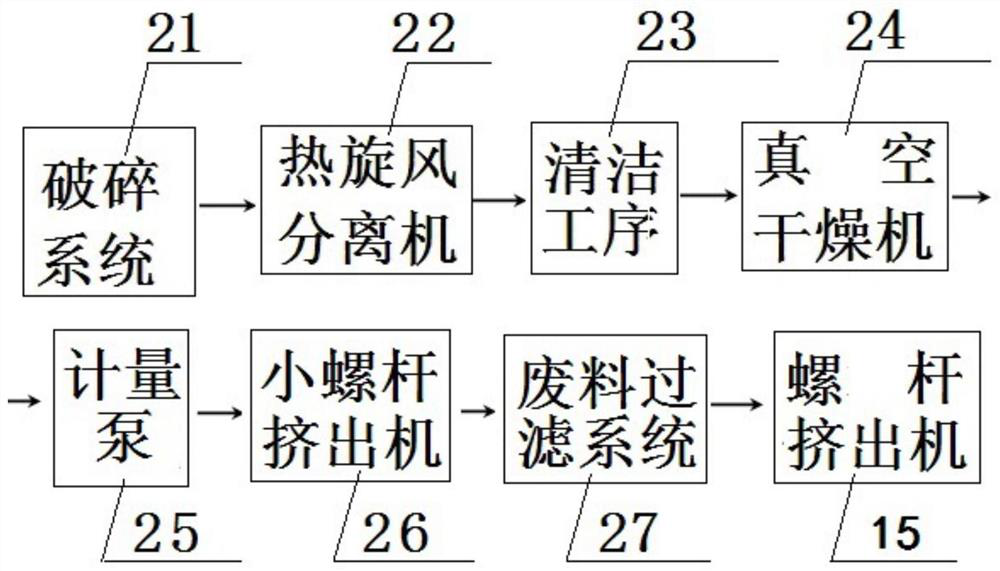

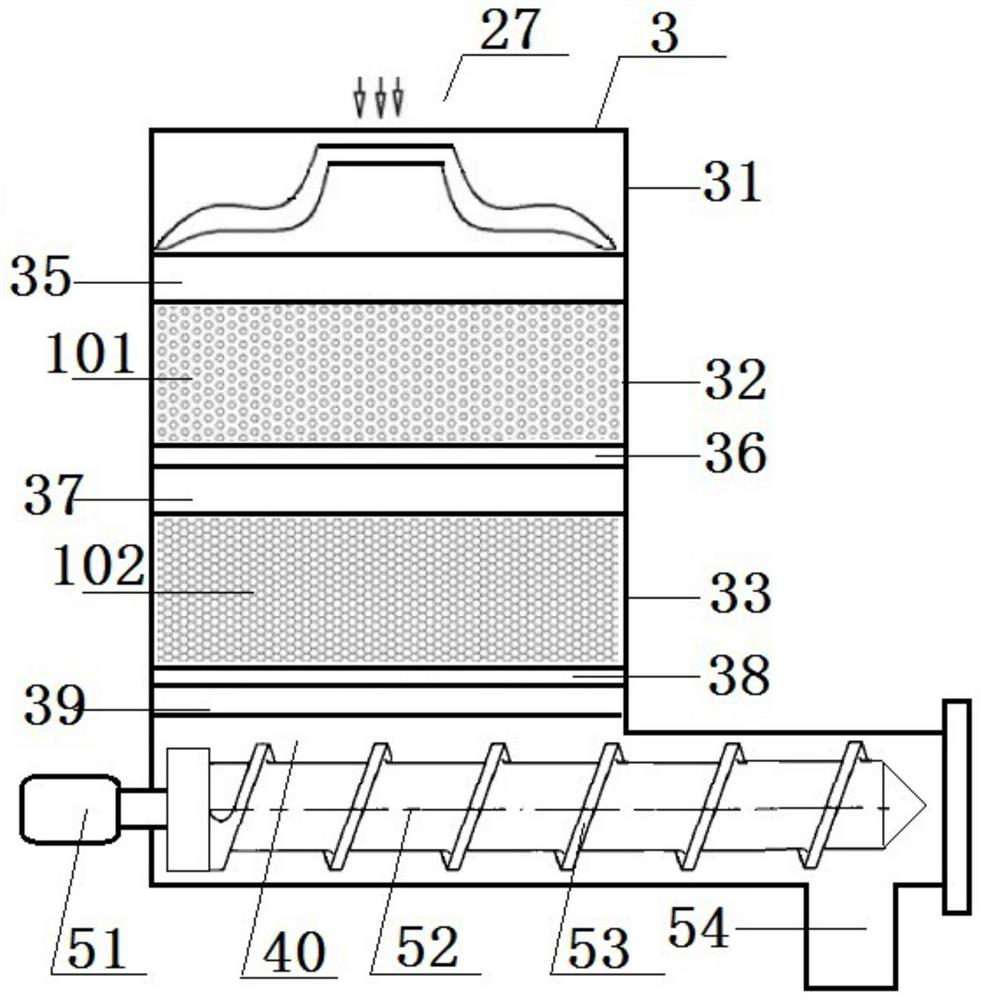

[0072] as attached Figure 1 to Figure 4 , Figure 6 and Figure 7 As shown, the waste non-woven fabric is regenerated to obtain a waste regenerated melt, including the following steps:

[0073] 1) Crushing step: In this step, the waste nonwoven fabric crushing system 21 is a crusher, and the waste nonwoven fabric is broken into sheet-like fabrics with a size not larger than 30mm×30mm by using the crusher.

[0074] 2) The step of pretreatment: adopt the hot cyclone separator 22 to separate the dust, sundries and fine powder in the sheet cloth in step (1), then enter the cleaning process 23 of the sheet cloth, in the cleaning process 23 Washing with hot water at 60-80° C. to wash and remove impurities in the she...

Embodiment 2

[0084] Such as Figure 8 As shown, in this example, component A and component B are used as raw materials, and the regenerated waste nonwoven fabric obtained in Example 1 is added for spinning to obtain a bicomponent fiber, and then a bicomponent nonwoven fabric is obtained.

[0085] In this embodiment, a two-component spinning device is used for spinning, which consists of a first component device (ie component A) and a second component device (ie component B). in:

[0086] The first component device includes: drier 1119 (the first drier), feeding device 112, metering pump 113 (the first main metering system), screw extruder 115 (the first main screw melt extrusion system) . Filter 116 (first main filter system).

[0087] Likewise, the second component device includes: drier 121 ((second drier)), feeding device 122, metering pump 123 (second main metering system), screw extruder 125 (second main screw melt extrusion system), filter 126 (the second main filter system), the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com