Treatment system and treatment method of fluorine-containing and nitrate nitrogen-containing industrial waste water

A treatment method, nitrate nitrogen technology, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high operating cost and treatment cost, large amount of acid and alkali, etc., to reduce fixed investment cost, reduce floor area, and avoid the effect of adding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

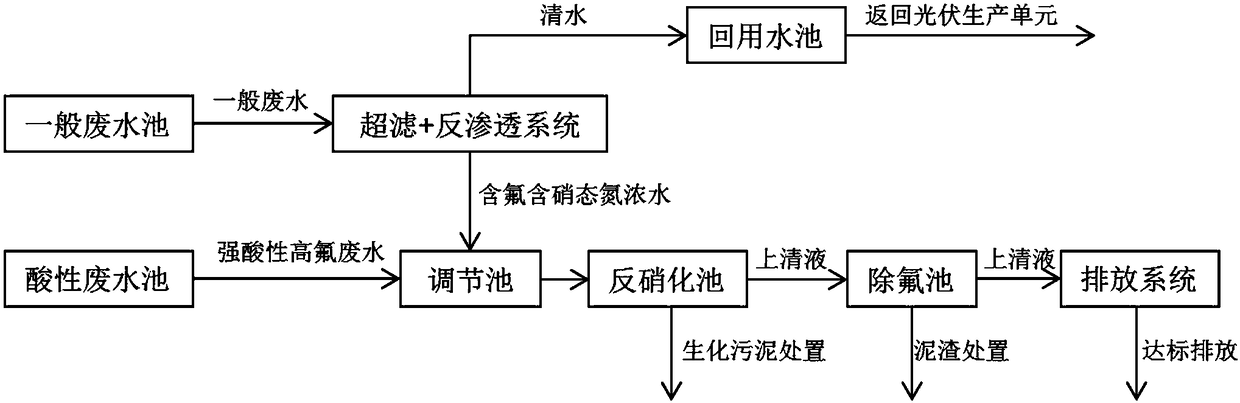

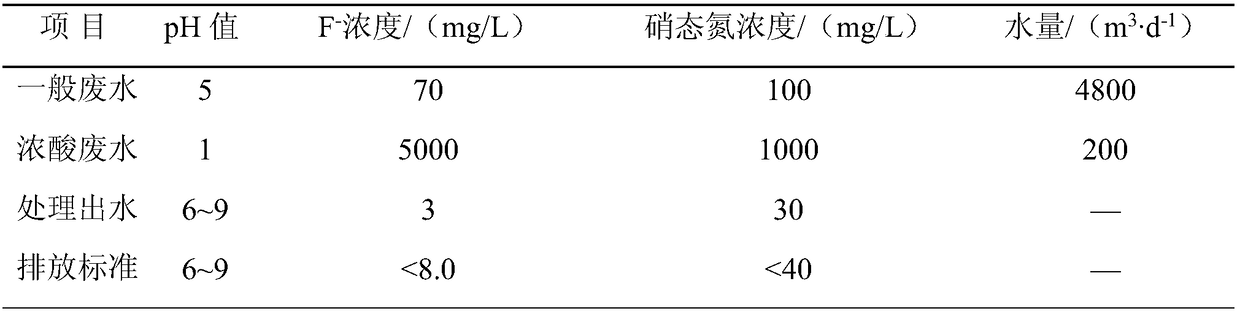

[0035] An example of a solar cell company's fluorine-containing wastewater treatment project. A company invested in a solar cell manufacturing project, and its discharged wastewater is mainly general wastewater and concentrated acid wastewater. The design scale of wastewater treatment project is 5000m 3 / d, divided into physical and chemical treatment and biochemical treatment.

[0036] General waste water mainly comes from the pure water cleaning waste water in each section, the regular drainage of the acid mist alkali spray tower, the waste gas incineration tail gas and the ammonia water cleaning gas water spray tower treatment and regular drainage. The ion concentration and nitrate nitrogen content are not high, and there is almost no organic matter. Therefore, pollutants with a particle size larger than 5 μm can be filtered out through activated carbon filters and security filters, and then directly introduced into ultrafiltration and reverse osmosis systems.

[0037] Con...

Embodiment 2

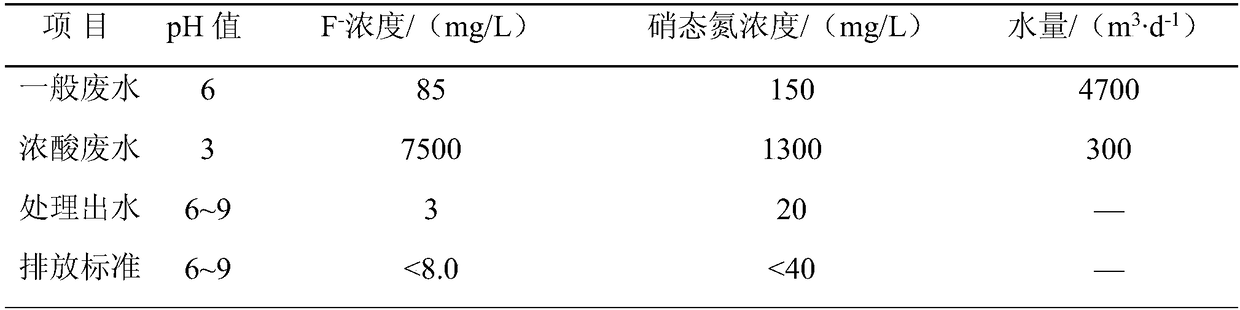

[0050] The waste water in this embodiment comes from another batch of waste water discharged by the solar cell enterprise, and the general waste water of this batch contains F - The concentration is 85mg / L, the concentration of nitrate nitrogen is 150mg / L, the pH is 6, the F of strongly acidic high-fluorine wastewater - The concentration is 7500mg / L, the nitrate nitrogen concentration is 1300mg / L, and the pH is 3. The treatment steps include:

[0051] (1) Collect the general wastewater after simple filtration in the general wastewater pool, and separate the general wastewater into fluorine-containing nitrate-nitrogen concentrated water and clear water through ultrafiltration and reverse osmosis systems. The concentrated nitrogen water is introduced into the adjustment tank, and the clear water is imported into the reuse pool; the ultrafiltration membrane used is DOW SFP-2880 purchased from Dow Chemical in the United States, and the reverse osmosis membrane used is BW30- 400FR...

Embodiment 3

[0060] The waste water in this embodiment comes from another batch of waste water discharged by the solar cell enterprise, and the general waste water of this batch contains F - The concentration is 100mg / L, the concentration of nitrate nitrogen is 200mg / L, the pH is 7, the F of strongly acidic high-fluorine wastewater - The concentration is 10000mg / L, the nitrate nitrogen concentration is 1600mg / L, and the pH is 5. The treatment steps include:

[0061] (1) Collect the general wastewater after simple filtration in the general wastewater pool, and separate the general wastewater into fluorine-containing nitrate-nitrogen concentrated water and clear water through ultrafiltration and reverse osmosis systems. The concentrated nitrogen water is introduced into the adjustment tank, and the clear water is imported into the reuse pool; the ultrafiltration membrane used is DOW SFP-2880 purchased from Dow Chemical in the United States, and the reverse osmosis membrane used is BW30- 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com