Manufacturing method of all solid state power lithium ion battery

A lithium-ion battery and a manufacturing method technology are applied in the manufacturing field of all-solid-state power lithium-ion batteries, which can solve the problems of large interface impedance, loss of specific capacity of pole pieces, and reduction of active material content of pole pieces, so as to reduce interface resistance, increase high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

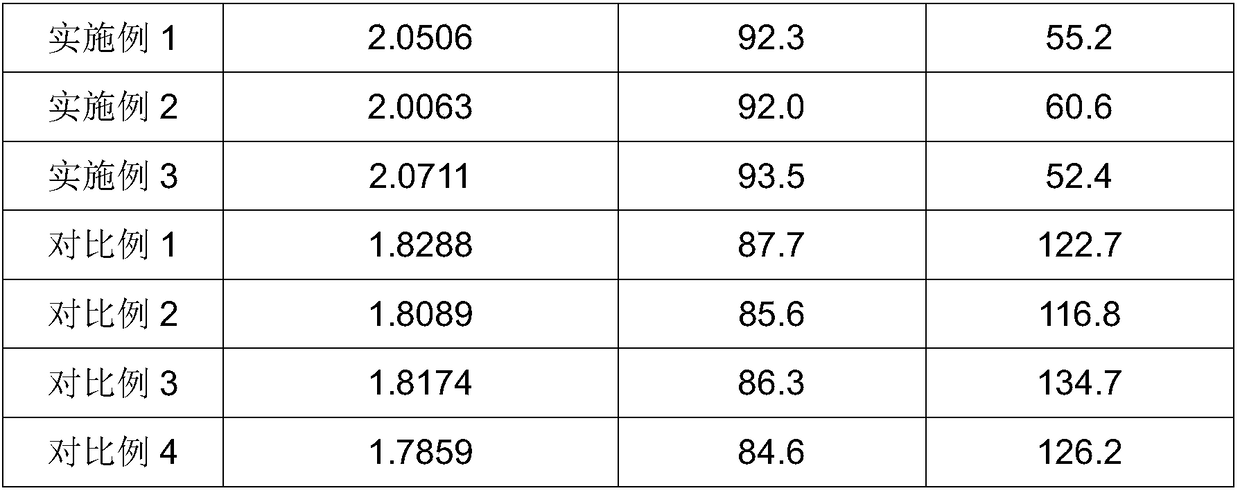

Embodiment 1

[0035] (1) The positive electrode slurry is prepared according to the following mass ratio: NCM523 positive electrode material 95%, Super PLi conductive agent 2%, HSV-900PVDF binder 1.5%; PEO solid electrolyte 1.5%, prepared by a double planetary mixer with NMP as a solvent A positive electrode slurry with a solid content of 65%.

[0036] (2) Negative electrode pulping is according to the following mass ratio: 96% of artificial graphite G9, 1% of conductive graphite conductive agent, 1.5% of HSV-900PVDF binder, 1.5% of PEO solid state electrolysis, prepared by double planetary mixer with NMP as solvent A negative electrode slurry with a solid content of 45%.

[0037] (3) The electrolyte solution is in accordance with the following mass ratio: PEO polymer electrolyte 95%, Al 2 o 3 The filler ratio is 2%; LiPF 6 The proportion of lithium salt is 3%; an electrolyte solution with a solid content of 15% is prepared by using a double planetary mixer and using NMP as a solvent.

...

Embodiment 2

[0041] (1) Positive electrode pulping is according to the following mass ratio: 97% of NCA positive electrode material, 1% of acetylene black conductive agent, 1% of PTFE binder; 1% of PMMA solid electrolyte, prepared into a solid slurry with acetonitrile as solvent by double planetary mixer A positive electrode slurry with a content of 80%.

[0042] (2) Negative electrode pulping is according to the following mass ratio: silicon carbon negative electrode material accounts for 98%, vapor phase growth carbon fiber 0.5%, HSV-900PVDF binder 1%, PMMA series solid state electrolysis 0.5%, through double planetary mixer, with NMP as solvent A negative electrode slurry with a solid content of 30% was prepared.

[0043] (3) The electrolyte solution is in accordance with the following mass ratio: PMMA polymer electrolyte 80%, MOF filler ratio 10%; LiCF 3 SO 3 The proportion of lithium salt is 10%; an electrolyte solution with a solid content of 80% is prepared by using acetonitrile a...

Embodiment 3

[0047] (1) Positive electrode pulping is according to the following mass ratio: 87% of lithium iron phosphate positive electrode material, 5% of graphene conductive agent, 3% of PVA binder; 5% of PAN solid electrolyte, prepared by using NMP as a solvent through a double planetary mixer A positive electrode slurry with a solid content of 30%.

[0048] (2) Negative electrode pulping is according to the following mass ratio: hard carbon accounts for 89%, vapor-phase grown carbon fiber conductive agent 3%, CMC binder 3%, PAN series solid-state electrolysis 5%, through double planetary mixer, NMP is prepared as solvent. Negative electrode slurry with a solid content of 60%.

[0049] (3) The electrolyte solution is in accordance with the following mass ratio: PAN-based polymer electrolyte 98.5%, nano-SiO 2 The proportion of similar fillers is 0.5%; LiClO 4 The proportion of lithium salt is 1%; an electrolyte solution with a solid content of 10% is prepared by using a double planet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com