High-voltage electrolyte containing novel additive

An additive and high-voltage technology, which is applied in the field of lithium-ion batteries, can solve problems affecting battery safety performance and cycle stability, poor thermal stability, and material gram capacity decline, and achieve improved room temperature cycle performance, good negative electrode film-forming performance, Effect of Improving High Pressure Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

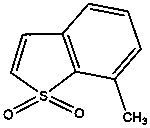

[0021] A high-voltage electrolyte solution for a lithium ion battery and a lithium ion battery, the electrolyte solution includes an additive containing methyl dibenzothiophene sulfone, and its structural formula is:

[0022]

[0023] When the high-voltage additive is used in the lithium-ion battery electrolyte, the mass percentage in the electrolyte is 5%, the massfraction of ethylene sulfate is 6%, and the organic solvent in the electrolyte is ethylene carbonate (EC ), dimethyl carbonate (DMC) and ethyl methyl carbonate (EMC), wherein the mass ratio of ethylene carbonate, dimethyl carbonate and ethyl methyl carbonate is 1:1:1, and the electrolyte of lithium-ion batteries is 1M LiPF 6 , denoted as electrolyte 1.

Embodiment 2

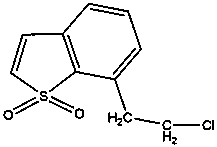

[0027] A high-voltage electrolyte solution for a lithium ion battery and a lithium ion battery, the electrolyte solution includes an additive of chloroethyl dibenzothiophene sulfone, and its structural formula is:

[0028]

[0029] When the high-voltage additive is used in the lithium-ion battery electrolyte, the mass percentage in the electrolyte is 7%, and the mass fraction of ethylene sulfate is 5%. The organic solvent in the electrolyte is a mixture of ethylene carbonate (EC), dimethyl carbonate (DMC) and ethyl methyl carbonate (EMC), wherein the mass ratio of ethylene carbonate, dimethyl carbonate and ethyl methyl carbonate is 1: 1: 1, the electrolyte of the lithium-ion battery is 1.1M LiBOB, which is recorded as electrolyte 3.

Embodiment 3

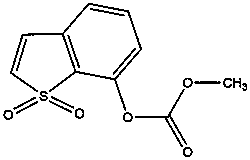

[0033] A high-voltage electrolyte solution for a lithium ion battery and a lithium ion battery, the electrolyte solution includes an additive of methyl carbonate benzothiophene sulfone, and its structural formula is:

[0034]

[0035] When the high-voltage additive is used in the lithium-ion battery electrolyte, the mass percentage in the electrolyte is 5%, and the mass fraction of ethylene sulfate is 8%. The organic solvent in the electrolyte is a mixture of ethylene carbonate (EC), dimethyl carbonate (DMC) and diethyl carbonate (DEC), wherein the mass ratio of ethylene carbonate, dimethyl carbonate and diethyl carbonate is 1:1:1, the electrolyte of the lithium-ion battery is 1.2M LiPF respectively 6 , denoted as electrolyte 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com