Ion stabilizer doped perovskite film as well as preparation method and application thereof

A technology of doping ions and stabilizers, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc. It can solve problems such as battery hysteresis, device service life reduction, and device performance deterioration, so as to improve stability and prolong Device life, the effect of promoting industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also discloses a method for preparing a perovskite film doped with an ion stabilizer as described above, comprising the following steps:

[0048] Step S11, preparing a perovskite solution;

[0049] Step S12, adding an ion stabilizer to the perovskite solution, heating and stirring at 70° C. for 2 hours to obtain a perovskite stabilizer mixed solution;

[0050] Step S13, coating the perovskite stabilizer mixture on the substrate deposited with the transport layer to form a layer containing perovskite A thin film layer of the stabilizer mixed solution, and the thin film layer is annealed to obtain a perovskite thin film layer doped with an ion stabilizer;

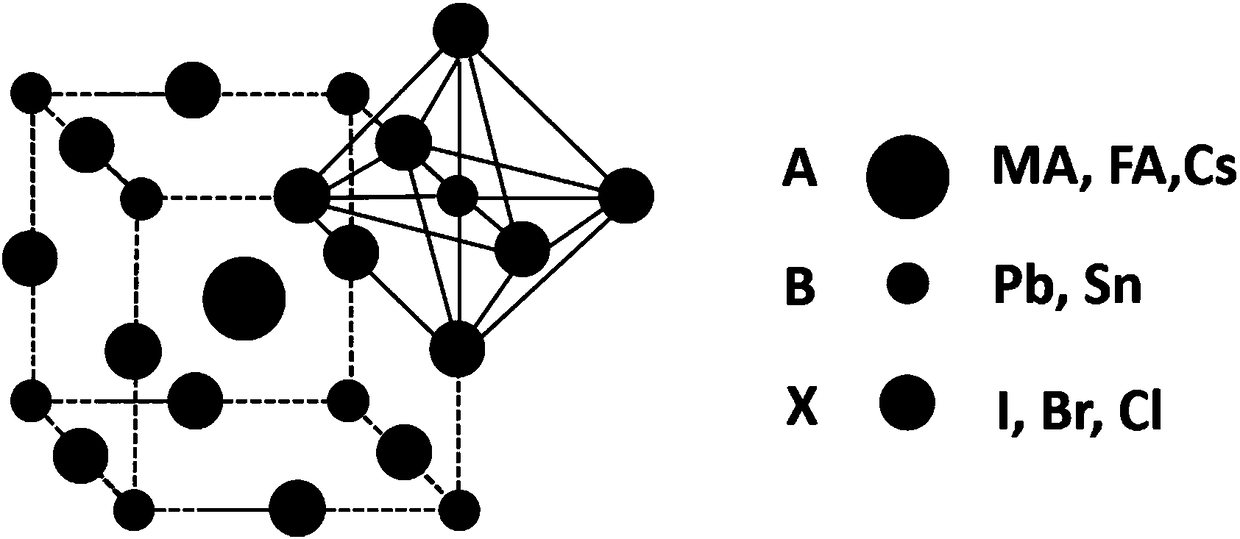

[0051] In step S11, the perovskite solution is mixed with at least one divalent metal halide precursor BX 2 A solution containing at least one reactant AX and an organic solvent, B is a divalent metal cation: lead, tin, tungsten, copper, zinc, gallium, germanium, arsenic, selenium, rhodium, pall...

example 1

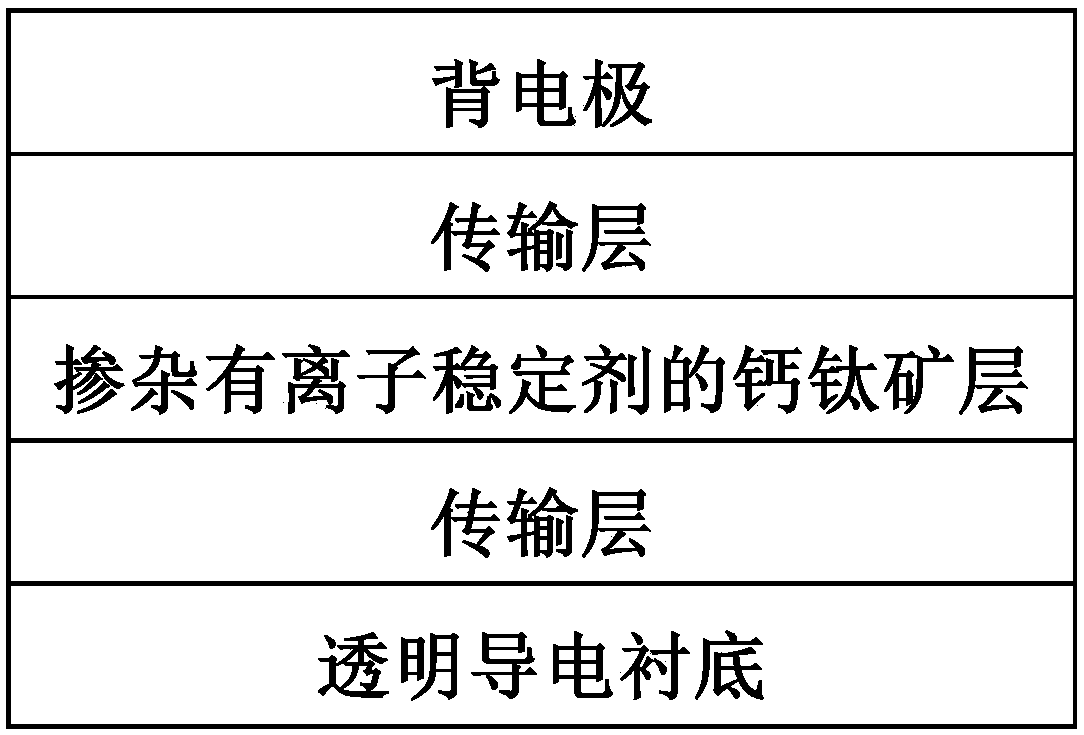

[0074] Example 1, a preparation method of a perovskite solar cell - solution mixing method, please refer to the attached figure 2 The schematic diagram of the internal structure of the perovskite solar cell shown includes the following steps:

[0075] (1) Clean a 10×10cm FTO glass plate with detergent, deionized water, acetone, and isopropanol for 30 minutes, and then use N 2 After drying, it was treated with UV O-zone for 10 minutes;

[0076] (2) Preparation of CuSCN film as a hole transport layer;

[0077] (3) Preparation of perovskite solution: 461 mg of PbI 2 (1mmol), 159mg of MAI (1mmol) were dissolved in 1mL of DMF solution, 70.9uL of anhydrous DMSO was added, and 36.9mg of tetrabutylammonium iodide (0.1mmol) was added as an ion stabilizer, heated and stirred at 70°C for 2h , ready to use after mixing completely;

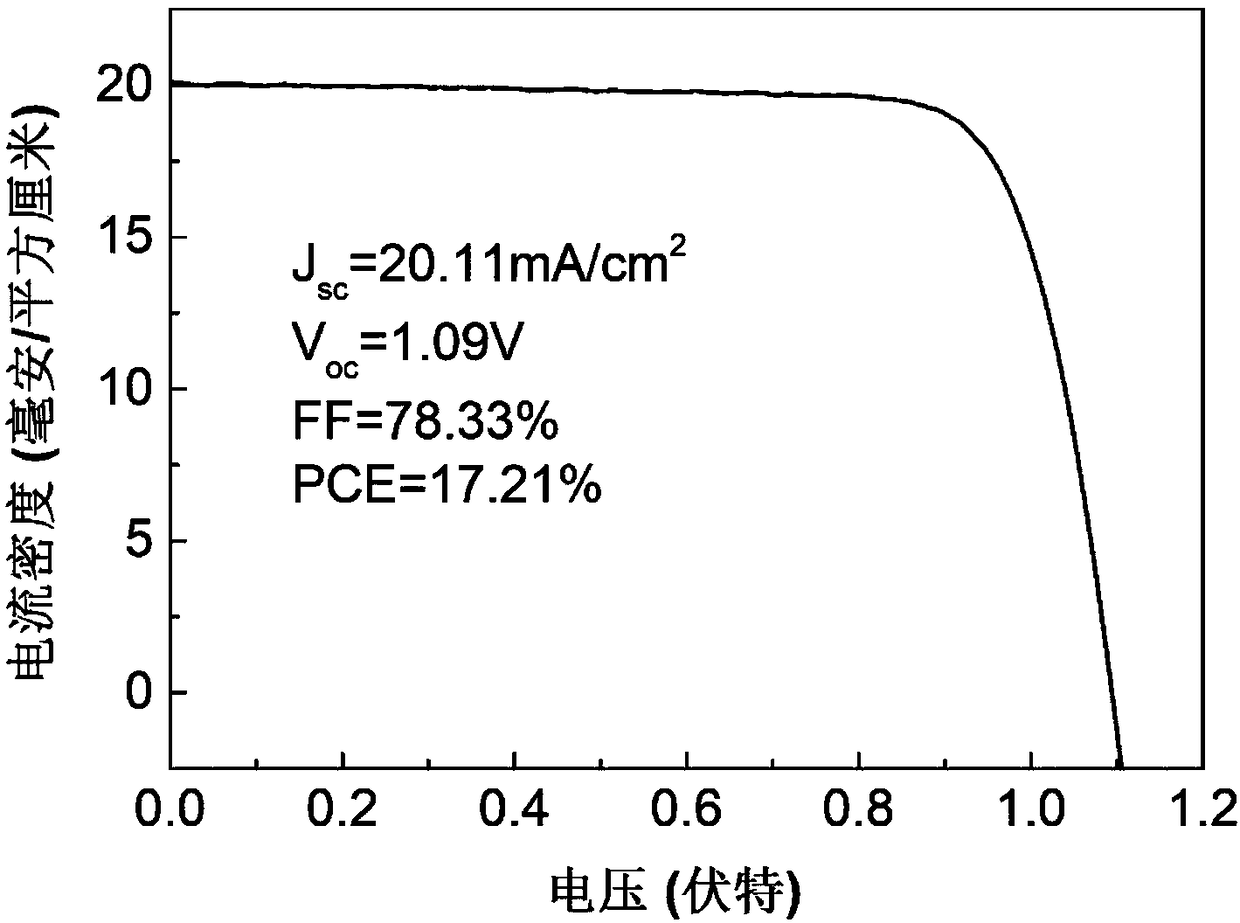

[0078] (4) Use the doped perovskite solution to prepare the perovskite film doped with stabilizer by slit coating, and anneal at 60~150°C for 10~120min, ...

example 2

[0081] Example 2, a preparation method of perovskite solar cells - vapor phase assisted deposition method, please refer to the attached figure 2 The schematic diagram of the internal structure of the perovskite solar cell shown includes the following steps:

[0082] (1) Clean a 5×5cm ITO glass plate with detergent, deionized water, acetone, and isopropanol for 30 minutes, and then use N 2 After drying, it was treated with UV O-zone for 10 minutes;

[0083] (2) Preparation of NiO x The thin film acts as a hole transport layer;

[0084] (3) Preparation of precursor stabilizer mixture: 461mg of PbI 2 (1mmol), dissolved in 1mL of DMF solution, add 70.9uL of anhydrous DMSO, and add 13.4μL of phenethanethiol (0.1mmol) as an ion stabilizer, heat and stir at 70°C for 2h, mix completely and set aside;

[0085] (4) Prepare stabilizer-doped PbI by slot coating using the prepared stabilizer mixture 2 film;

[0086] (5) The prepared PbI doped with stabilizer 2 The film substrate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com