LDS (Laser Direct Structuring) coating capable of being activated by laser as well as preparation method and application of LDS coating

A laser activation and coating technology, applied in the field of coatings, can solve the problems of long curing time of LDS antenna coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

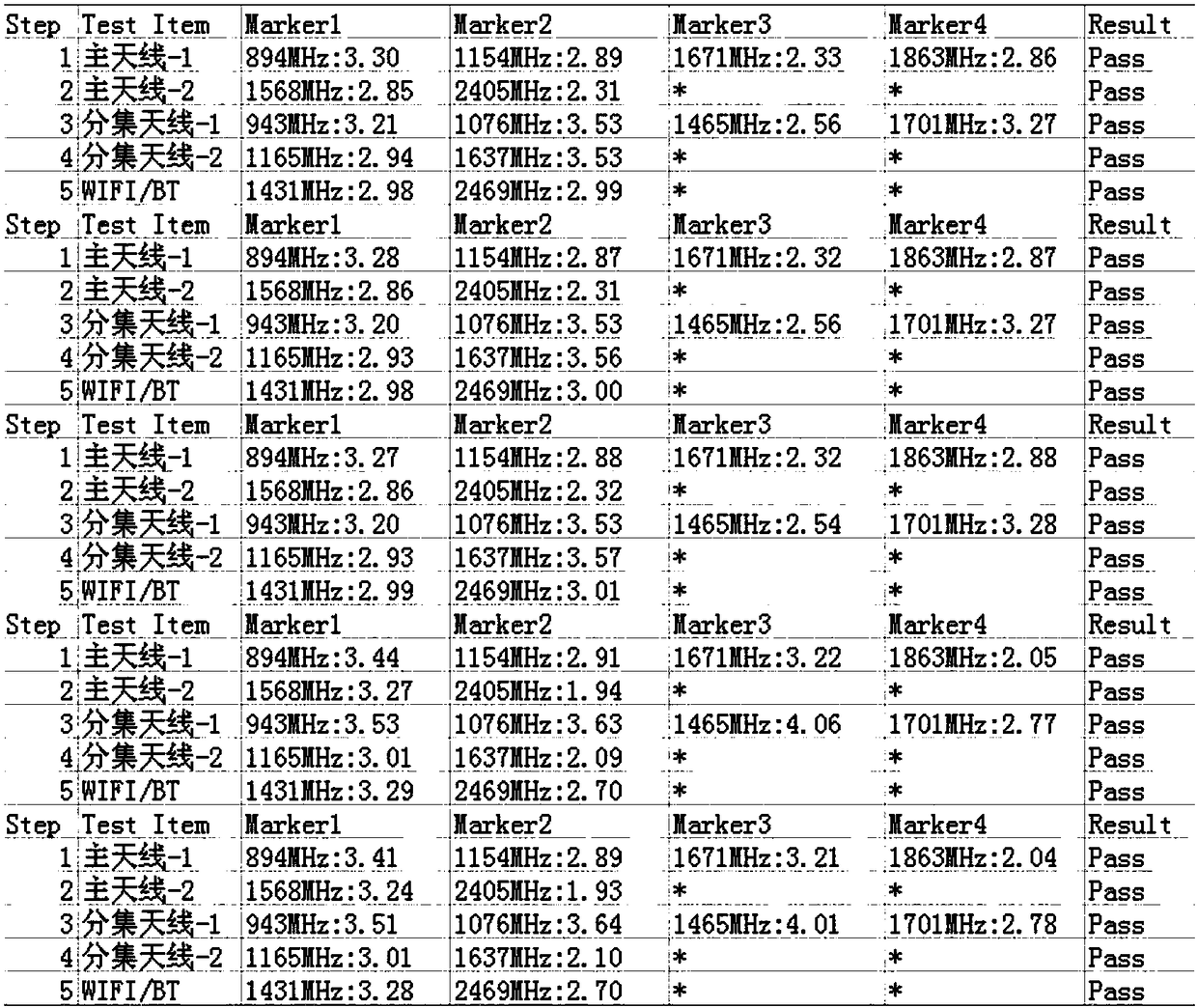

Image

Examples

preparation example Construction

[0055] The present invention provides the preparation method of LDS coating described in above-mentioned technical scheme, comprises the following steps:

[0056] mixing resin, LDS laser powder, solvent, dispersant and filler to obtain the first mixed material;

[0057] Mixing the first mixed material with a defoamer and a leveling agent to obtain a second mixed material;

[0058] The second mixed material is mixed with a curing agent and a curing accelerator to obtain an LDS coating.

[0059] The invention mixes resin, LDS laser powder, solvent, dispersant and filler to obtain the first mixed material. The present invention has no special restrictions on the mixing of the resin, LDS laser powder, solvent, dispersant and filler, and the technical solution of material mixing well known to those skilled in the art can be adopted; in the embodiments of the present invention, specifically, the Add the resin, LDS laser powder, solvent, dispersant and filler into the grinder and g...

Embodiment 1

[0065] In parts by weight, the laser-activatable LDS coating prepared in this embodiment includes the following components:

[0066] 60 parts of bisphenol A type epoxy resins, 8 parts of Sanlaser 8800LDS laser powders, 9 parts of solvent butyl acetates, 20 parts of V140 type polyamide curing agents, 6 parts of curing accelerators (dimethylimidazole and The mass ratio of cobalt naphthenate is 1:1), BYK-110 dispersant 0.8 parts, BYK-141 defoamer 0.6 parts, BYK-358 leveling agent 0.5 parts;

[0067] The preparation method of the laser-activatable LDS coating comprises the following steps:

[0068] Add bisphenol A type epoxy resin, LDS laser powder, butyl acetate and dispersant to the grinder and grind for 20min to obtain the first mixed material;

[0069] Add the first mixed material, defoamer, and leveling agent into a high-speed disperser, and disperse at 1000r / min for 10 minutes to obtain the second mixed material;

[0070] Add the second mixed material, curing agent, dimeth...

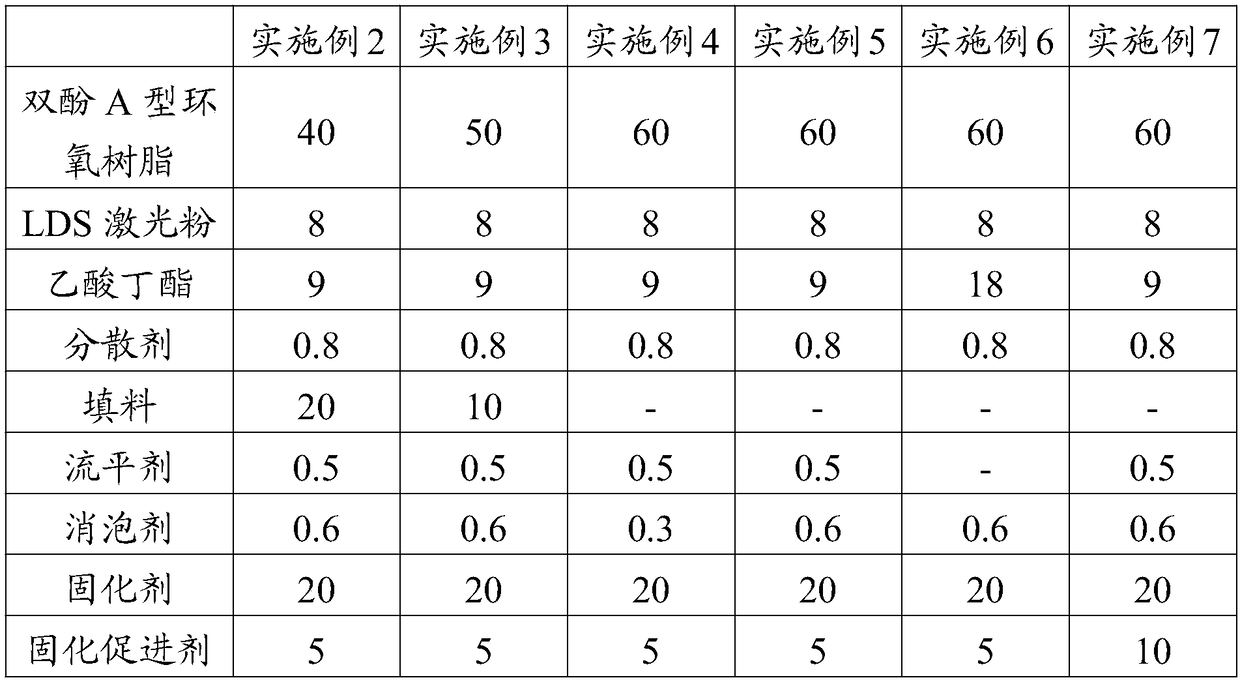

Embodiment 2~7

[0072] A laser-activatable LDS paint was prepared according to the method of Example 1, the difference being the distribution ratio of each component; see Table 1 for the distribution ratio of the components in Examples 2-7.

[0073] The component distribution ratio (parts by weight) of Table 1 Embodiment 2~7

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com