Polymethylacrylic acid higher ester pour point depressant, and preparation method and application thereof

A technology of polymethacrylic acid and methacrylic acid, which is applied in the direction of fuel additives, liquid carbon-containing fuels, fuels, etc., can solve the problems of poor optical properties of products, long process flow, etc., and achieve the effect of simple and feasible methods and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

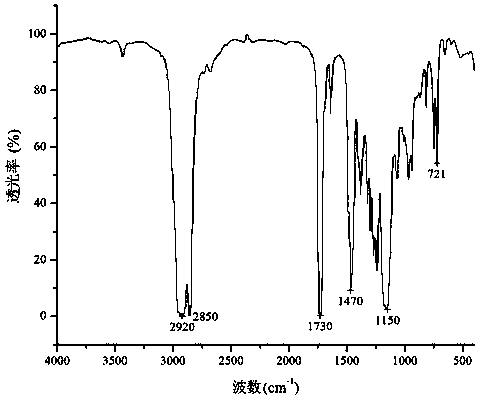

Image

Examples

Embodiment 1

[0031] A kind of polymethacrylic acid advanced ester type pour point depressant, polymerization reaction formula is as shown in formula (I) and formula (II):

[0032]

[0033] The invention uses the asymmetric bis-Schiff base late transition metal complex as a catalyst and azobisisobutyronitrile or benzoyl peroxide as an initiator to catalyze the homopolymerization or copolymerization of higher esters of methacrylic acid under anhydrous and oxygen-free conditions. , to obtain the polymers represented by the corresponding formulas (I) and (II), and used for depressing the diesel fraction and the lubricating oil fraction, the effect is obvious.

Embodiment 2

[0034] Embodiment 2: a kind of preparation method of polymethacrylic acid advanced ester type pour point depressant, comprises the following steps:

[0035] 1) For refining of lauryl methacrylate, add 200 ml of commercially available lauryl methacrylate and 2 grams of CaH to a 500 ml round bottom flask 2 , zeolite and magneton at room temperature and stirred for 10 hours to remove the polymerization inhibitor therein. Carry out underpressure distillation then, the lauryl methacrylate after the gained refining is sealed and kept at low temperature;

[0036] 2) For the polymerization of lauryl methacrylate, add 0.0054 mmol of 2-hydroxy-3,5-di-tert-butyl-benzaldehyde-o-phenylenediamine-Ni-salicyl to a 100ml pre-dried polymerization reaction tube Aldehyde as catalyst, 0.0027mmol initiator azobisisobutyronitrile, through Schlenk device, replace oxygen three times with 99.99% high-purity nitrogen, add 2.5ml pre-treated lauryl methacrylate, 5ml toluene, in nitrogen atmosphere Lower...

Embodiment 3

[0040] A preparation method of polymethacrylic acid advanced esters pour point depressant, comprising the following steps:

[0041] 1) For the refining of advanced methacrylic acid esters, add 300ml or corresponding quality of commercially available advanced methacrylic acid esters and 5 grams of CaH to a 500ml round bottom flask 2 , zeolite and magneton at room temperature and stirred for 15 hours to remove the polymerization inhibitor therein, then carry out vacuum distillation, and the obtained refined methacrylic acid high-level esters are sealed and stored at low temperature;

[0042]2) Polymerize the higher esters of methacrylic acid prepared in step 1), add 0.0108mmol of catalyst and 0.054mmol of initiator benzoyl peroxide into a 100ml pre-dried polymerization reaction tube, pass through the Schlenk device, use Replace oxygen with 99.99% high-purity nitrogen three times, add pre-treated 5ml or corresponding quality methacrylic acid advanced ester monomer and 10ml benzen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com