Method for preparing silicon carbide nanofiber

A nanofiber, silicon carbide technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of being unsuitable for industrial scale production, low generation efficiency of electrospinning, etc., and achieve high tensile strength, low cost, and a wide range of sources. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

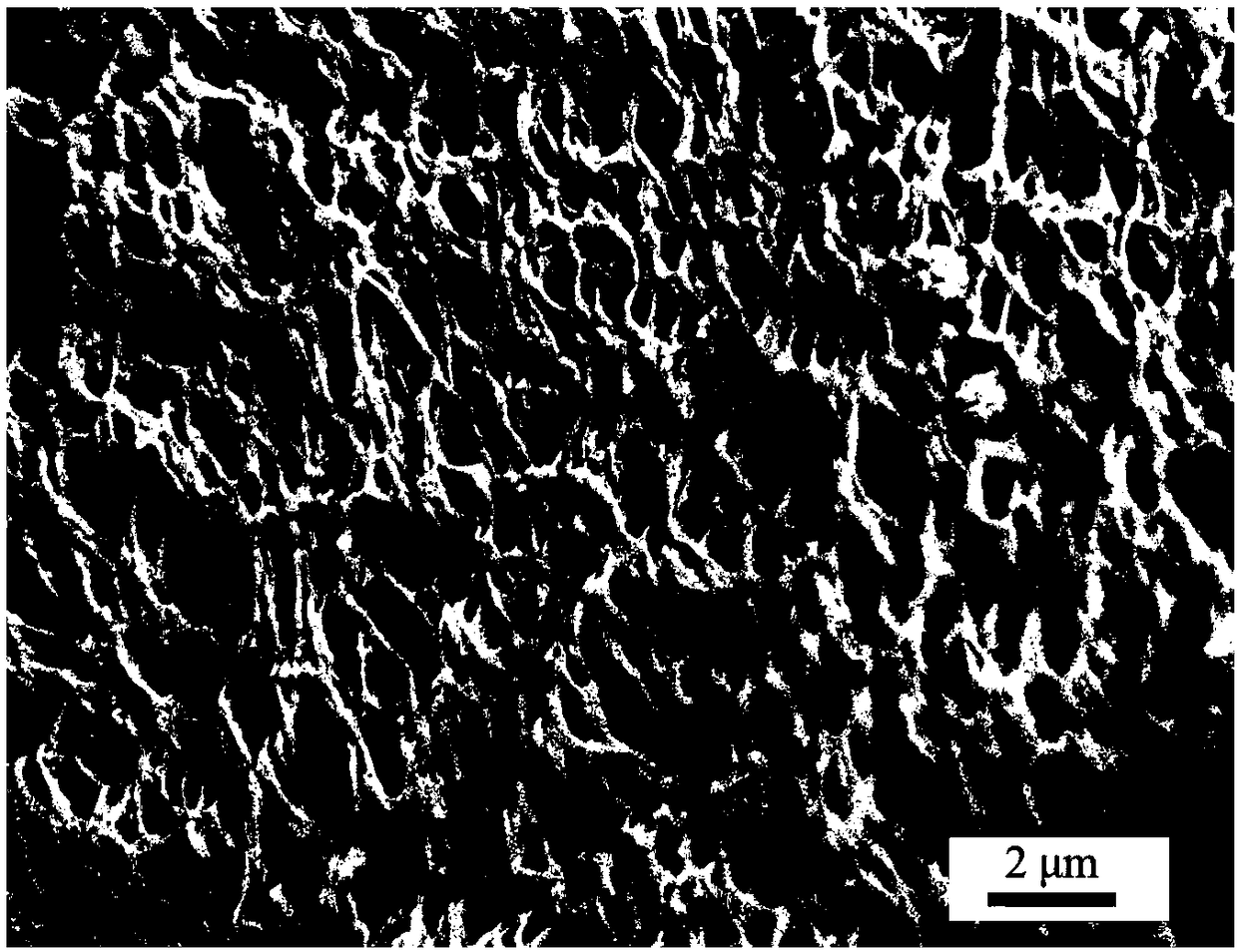

Image

Examples

Embodiment 1

[0027] This embodiment relates to a method for preparing silicon carbide nanofibers, which specifically includes the following steps:

[0028] 1. Dissolve 0.5g polycarbosilane in 9.5g ternary mixed solvent, in which N,N-dimethylformamide: 1,4-dioxane: tetrahydrofuran = 5:1:2 in the ternary solvent, Stir magnetically at room temperature for 3 hours, and prepare a polycarbosilane solution with a mass concentration of 5%.

[0029] 2. Pour the polycarbosilane solution into a petri dish with a diameter of 5 cm, put it in a preset -20°C refrigerator, and quench it for 120 minutes. After quenching, quickly take out the Petri dish, add 200mL ethanol to the Petri dish for extraction, remove the ternary solvent, change ethanol once every 6h, and change ethanol 4 times continuously. Freeze-dried for 24 hours to obtain the first precursor.

[0030] 3. Under the protection condition of helium gas, the first precursor is subjected to radiation cross-linking, and the electron beam intensit...

Embodiment 2

[0036] This embodiment relates to a method for preparing silicon carbide nanofibers, which specifically includes the following steps:

[0037] 1. Dissolve 0.5g polycarbosilane in 9.5g ternary mixed solvent, where N,N-dimethylformamide: 1,4-dioxane: tetrahydrofuran = 5:1:3 in the ternary solvent, Stir magnetically at room temperature for 3 hours, and prepare a polycarbosilane solution with a mass concentration of 5%.

[0038] 2. Pour the polycarbosilane solution into a petri dish with a diameter of 5 cm, put it in a preset -20°C refrigerator, and quench it for 120 minutes. After quenching, quickly take out the petri dish, add 200mL ethanol to the petri dish for extraction, remove the ternary solvent, change ethanol once every 6h, and change ethanol 4 times continuously. Freeze-dried for 24 hours to obtain the first precursor.

[0039] 3. Under the protection condition of helium gas, the first precursor was subjected to radiation cross-linking, and the electron beam intensity ...

Embodiment 3

[0045] This embodiment relates to a method for preparing silicon carbide nanofibers, which specifically includes the following steps:

[0046] 1. Dissolve 1.0g polycarbosilane in 9.0g ternary mixed solvent, where N,N-dimethylformamide: 1,4-dioxane: tetrahydrofuran = 5:2:3 in the ternary solvent, Stir magnetically at room temperature for 3 hours, and prepare a polycarbosilane solution with a mass concentration of 10%.

[0047] 2. Pour the polycarbosilane solution into a petri dish with a diameter of 5 cm, put it into a preset -30°C refrigerator, and quench it for 90 minutes. After quenching, quickly take out the Petri dish, add 200mL ethanol to the Petri dish for extraction, remove the ternary solvent, change ethanol once every 6h, and change ethanol 4 times continuously. Freeze-dry for 24 hours to obtain the first precursor.

[0048] 3. Under the protection condition of helium gas, the first precursor is subjected to radiation crosslinking, the electron beam intensity is 300KG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com