Method of micro-arc oxidation for steel surface

A micro-arc oxidation, steel technology, applied in anodizing, arc welding equipment, manufacturing tools, etc., to achieve the effect of beautiful weld formation and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

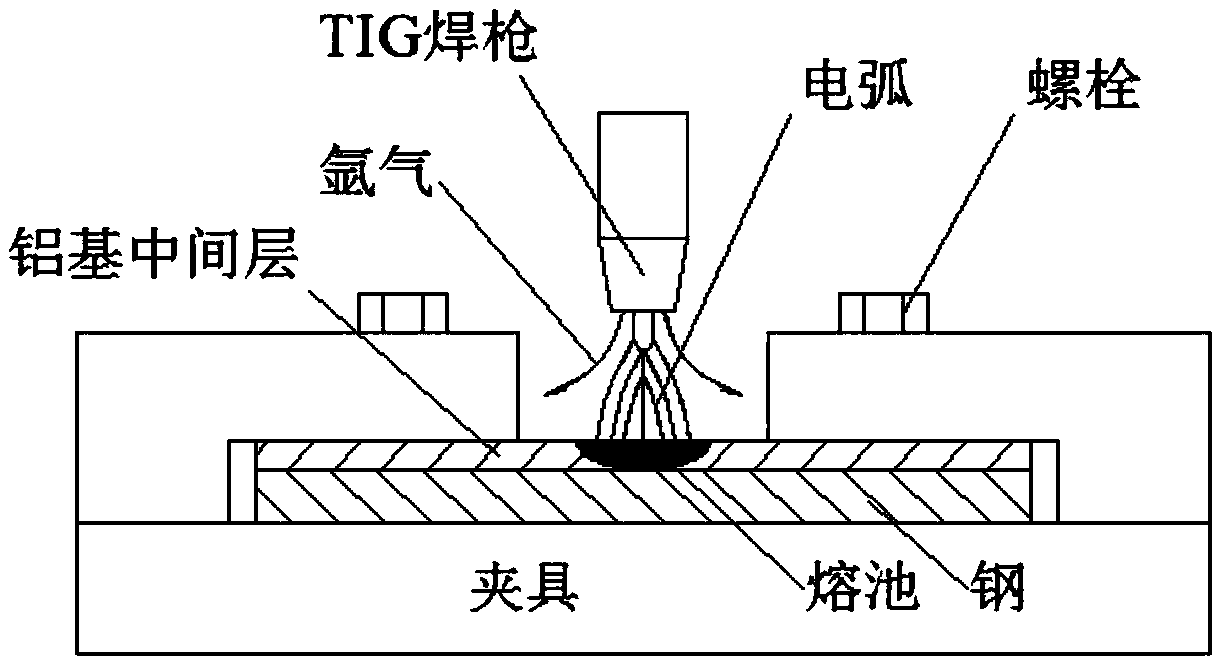

[0020] Before welding, the steel plate and aluminum plate are polished brightly. The size of the Q235 steel plate is 200mm×100mm×3mm, and the size of the 5A06 aluminum alloy plate is 200mm×100mm×1.5mm. and cleaned with acetone. Tungsten argon arc welding machine is used, the steel plate is on the bottom, and the aluminum plate is on the top for welding. The welding form is as follows figure 1 shown. AlSi was used in the experiment 5 Welding wire is used as solder. In order to facilitate the tensile and shear performance test to detect the strength of the steel-aluminum bonding interface, a lap joint is used. The lap width is 10 mm, and the tungsten electrode is biased to the aluminum side by 2 mm. Different welding parameters are used, as shown in the table 2.

[0021] Table 2 welding parameters

[0022]

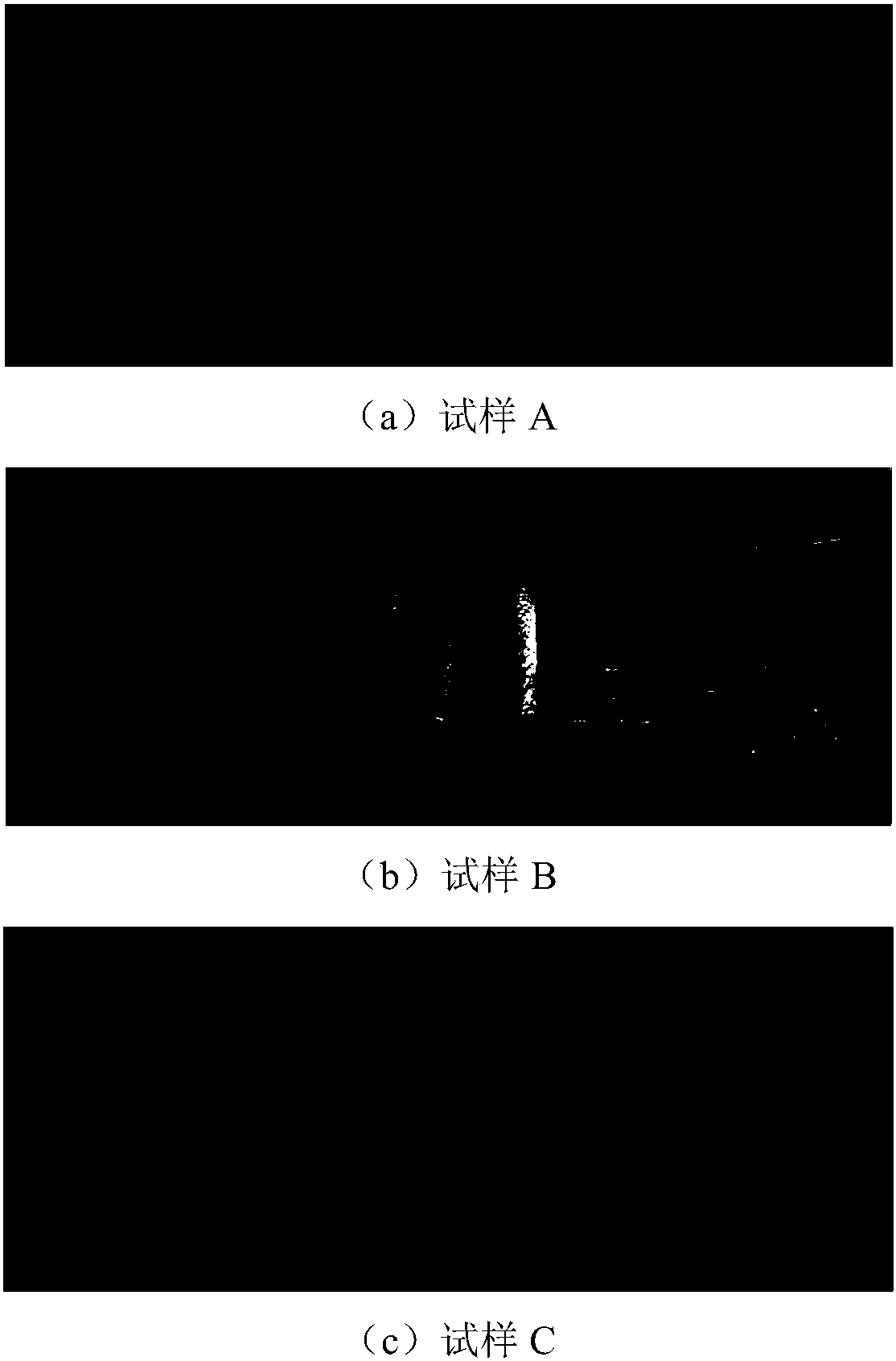

[0023] After welding, the weld seam is formed beautifully, and the specimen is subjected to tensile testing, and the specimen is broken at the weld seam, and the frac...

Embodiment 2

[0025] The test piece obtained by TIG melting-brazing was cut into a sample of 30mm×10mm×4.5mm, the surface was polished flat, and cleaned with acetone. The micro-arc oxidation equipment was used for the test, the parameters of the micro-arc oxidation process and the electrolyte parameters were: positive and negative 50% duty cycle, current density 10A / dm 2 , the frequency is 200Hz, 400Hz, 600Hz, 800Hz respectively, the micro-arc oxidation time is 30min, and the electrolyte is 1g / L KOH, 2g / L N a2 SiO 3 9H 2 O.

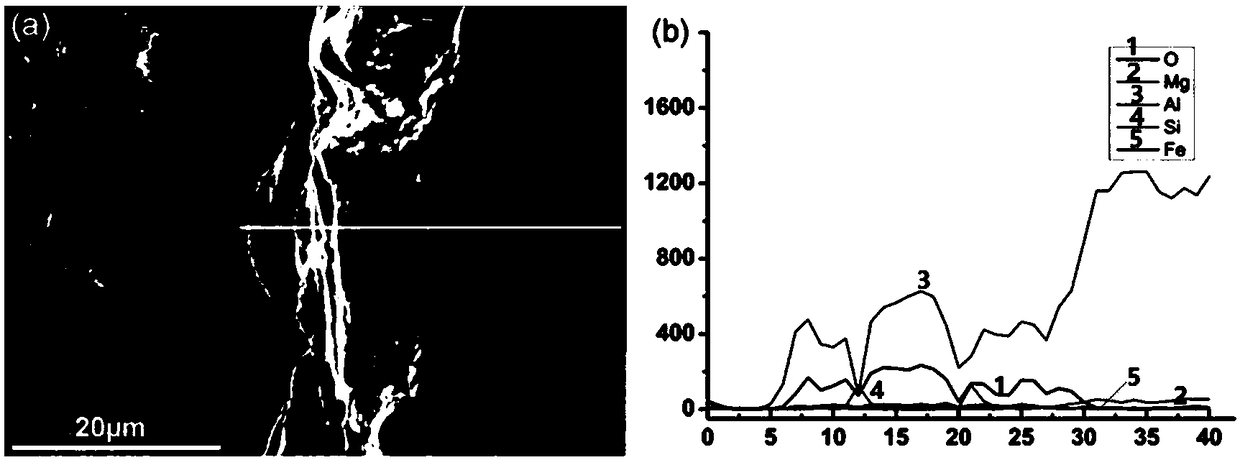

[0026] image 3 It is the cross-sectional morphology and EDS energy spectrum of the sample ceramic layer under the condition of micro-arc oxidation frequency of 400Hz. It can be seen from the figure that the ceramic layer is composed of a loose layer and a dense layer. The ceramic layer mainly contains aluminum, oxygen, silicon, and magnesium, among which the magnesium element mainly comes from the aluminum layer substrate, and the silicon and oxygen elements come...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com