Break-resistant ceramic cup and manufacturing process thereof

A ceramic cup and manufacturing process technology, applied in the field of ceramics, can solve problems such as crushing, and achieve the effect of improving hardness, firm and reliable adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

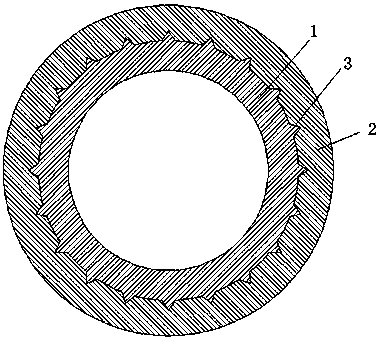

[0031] refer to figure 1 , a ceramic cup, including an inner water storage layer and an outer protective layer. The outer surface of the inner water storage layer is provided with several conical protrusions. The outer protective layer and the inner water storage layer are bonded into a whole. The protrusions make the inner water storage layer and the outer protective layer more stable and firm when they are bonded together, which greatly improves the connection strength.

[0032] The inner water storage layer is made of 10-20 grams of water glass, 45-60 grams of putrefaction wax, 5-10 grams of industrial alkali powder, 20-30 grams of quartz, 300-400 grams of pottery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com