Method for detecting ibuprofen raw material impurity F

A detection method and impurity technology, which is applied in the detection field of ibuprofen raw material impurity F, can solve the problems of strong acidity of trifluoroacetic acid, low separation degree, irritating odor of trifluoroacetic acid, etc., and achieve simple and fast detection, theoretical plate Large numbers and good operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

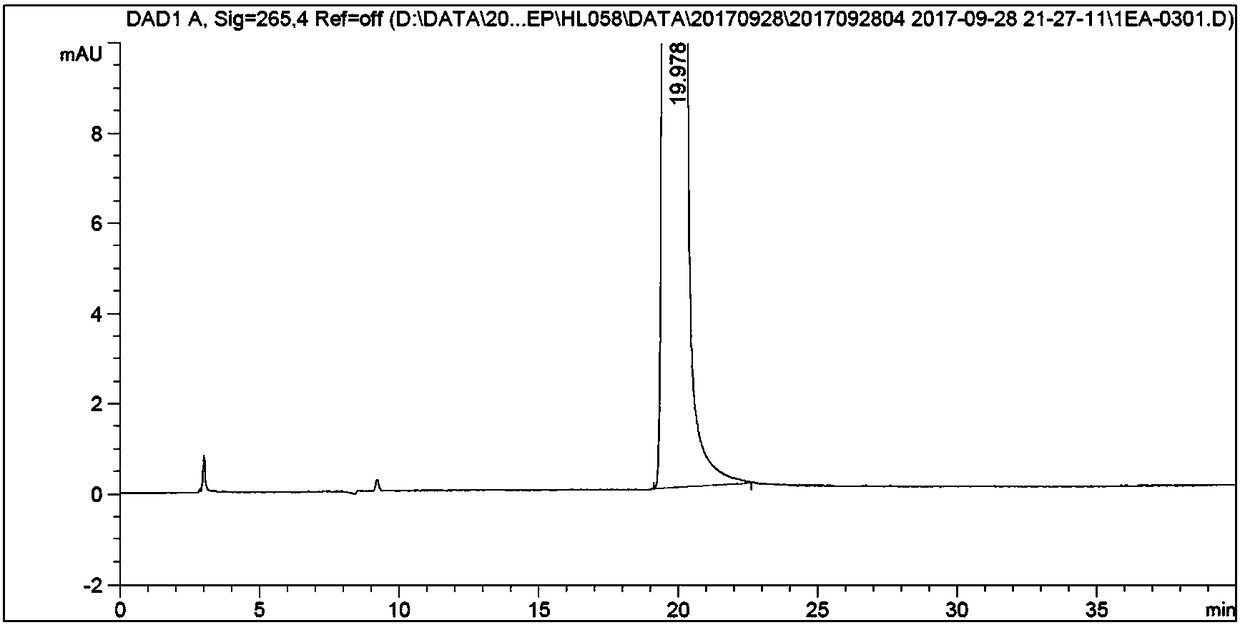

[0064] System suitability test: the separation degree between the impurity F and the main component peak is ≥2.0, and the system suitability is good; the number of impurity F theoretical plates meets the regulations.

Embodiment 2

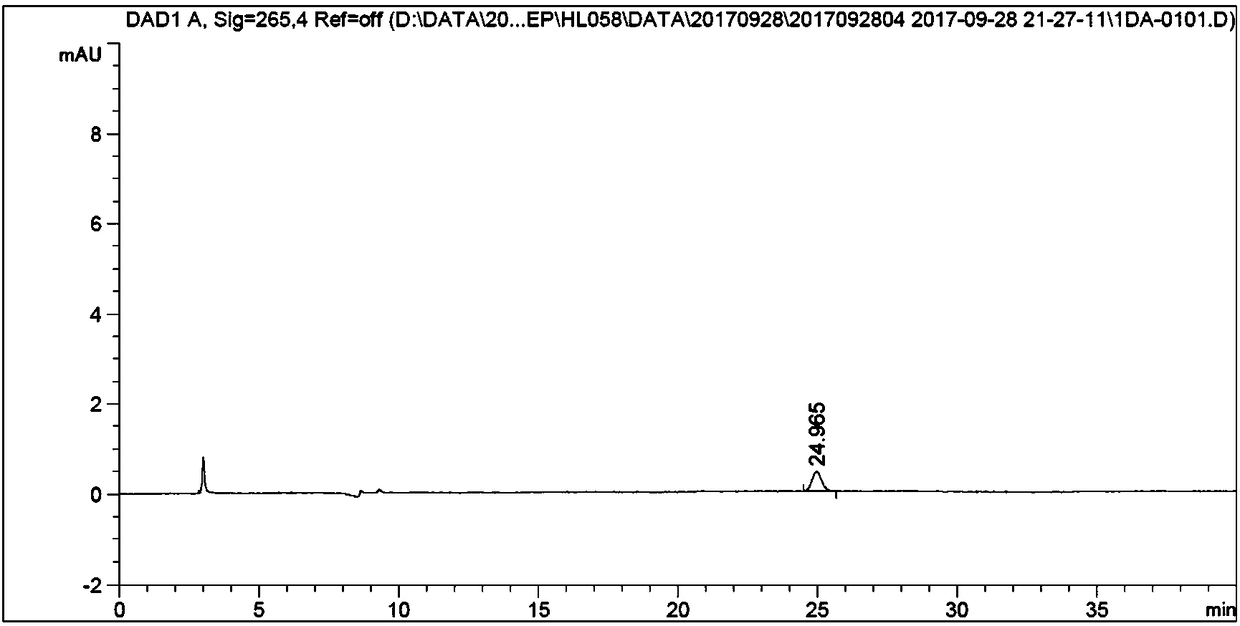

[0066] Specificity test: blank solvent chromatogram such as figure 1 As shown, it has no interference to the detection of impurity F peak; the separate impurity F chromatogram is shown in figure 2 Shown, the chromatogram of ibuprofen raw material is as follows image 3 As shown, the spectrogram of the mixed sample of impurity F and ibuprofen is as Figure 4 as shown, Figure 2 ~ Figure 4 It shows that the separation between the impurity F and the main component peak is good. Under forced degradation conditions such as light and high temperature, the chromatogram of ibuprofen raw material is as follows: Figure 15 and 16 As shown, the impurities interfering with the impurity F were not detected, and the separation between the impurity F and the adjacent peak was in compliance with the regulations.

Embodiment 3

[0068] The stability of the solution: the test solution and the reference solution are stable at room temperature for 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com