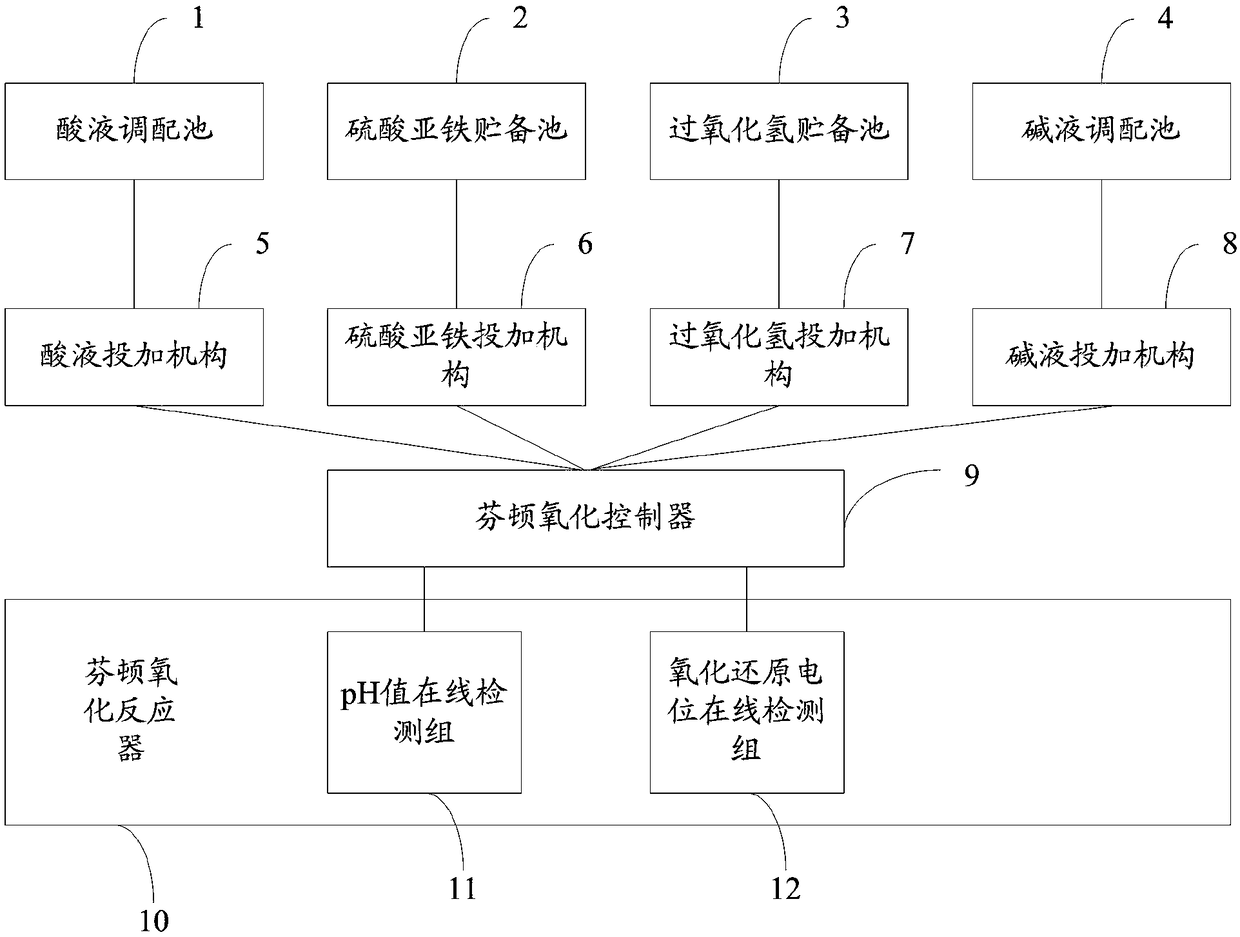

Automatic control device and method for Fenton oxidation reactor for treating lignite upgrading wastewater

An automatic control device, the technology of Fenton oxidation, applied in water treatment parameter control, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of destroying the conversion balance, difficult to achieve treatment effect, and increasing operational complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

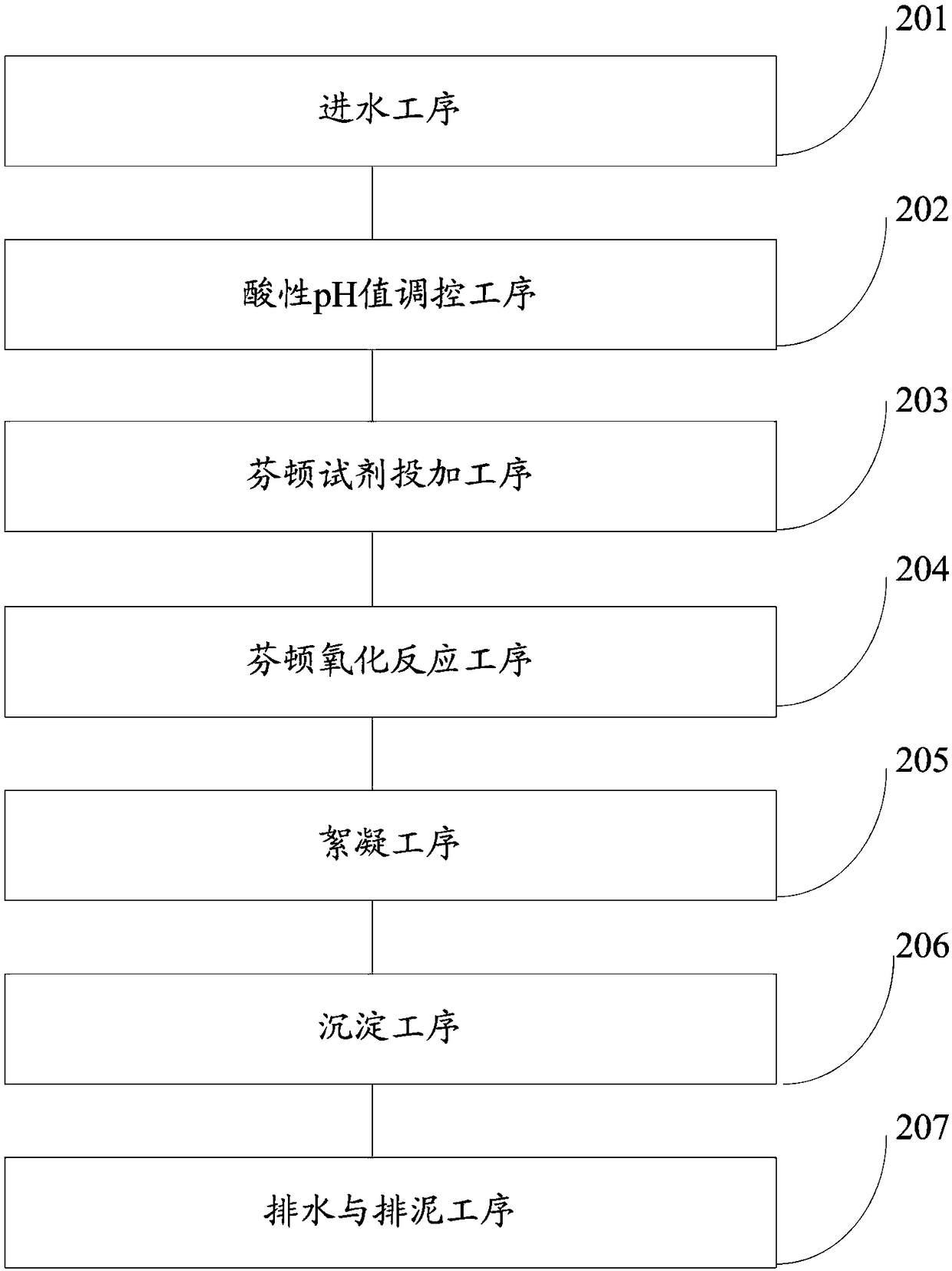

[0051] This embodiment is an automatic control method for the Fenton oxidation reactor for treating lignite upgrading wastewater, which is specifically completed according to the following steps:

[0052] The lignite upgrading wastewater after biochemical treatment is selected as the industrial wastewater to be treated, and the wastewater volume is 100-200m 3 / d, the COD concentration is 100-200mg / L, the ammonia nitrogen concentration is 10-30mg / L, and the SS concentration is 70-100mg / L.

[0053] figure 2 It is the process schematic diagram of the Fenton oxidation reactor automatic control method of the embodiment of the present invention, as figure 2 As shown, the automatic control method of the Fenton oxidation reactor mainly includes the following processes: water intake process 201, acid pH value control process 202, Fenton reagent addition process 203, Fenton oxidation reaction process 204, flocculation process 205, precipitation process 206 , Drainage and mud dischar...

specific Embodiment approach 2

[0062] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the hydraulic retention time is 8h, and the others are the same as Embodiment 1.

specific Embodiment approach 3

[0063] Embodiment 3. The difference between this embodiment and Embodiment 1 or 2 is that the number of sequencing batch Fenton oxidation reactors is 4, and the others are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com