Copper-steel-copper composite material for thin gauge electrical connector terminal and preparation method thereof

A technology for electrical connectors and composite materials, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc. Problems such as inability to produce independently, to achieve the effect of solving the inability to produce independently, reducing processes, and breaking through the lower limit of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

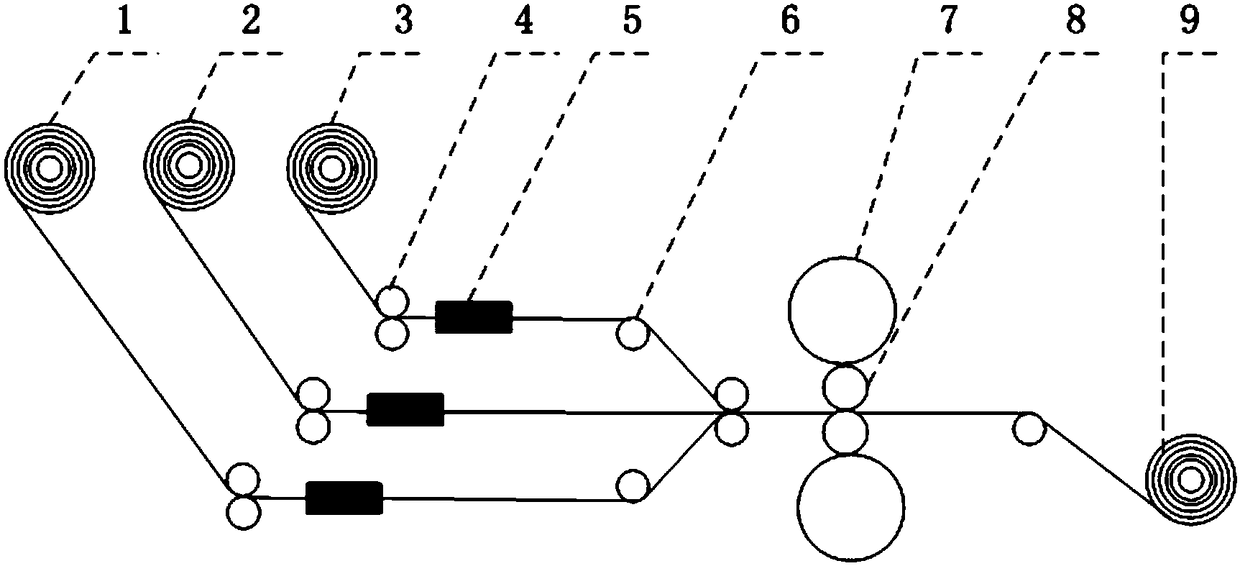

[0037] The T3 pure copper strip with a raw material thickness of 0.6mm and the Q235 steel strip with a thickness of 0.3mm are cold-rolled and composited to prepare a copper-steel-copper composite ultra-thin strip. The main steps are as follows:

[0038] (1) Put the coiled copper strip, steel strip and copper strip respectively on three reels in order, and the ends of the three-layer metal strips are wound on the other side reel through the working roll gap of the rolling mill;

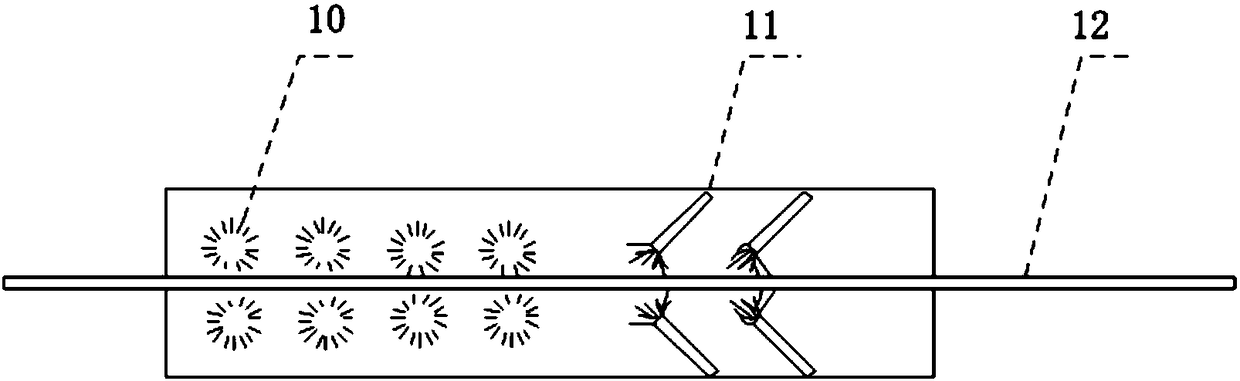

[0039] (2) Start the on-line processing device for the surface of the rolling mill, polish the surface of the copper strip and steel strip to be compounded with a steel brush, and start the air knife at the same time to blow and wash the polished metal surface. The online surface treatment device includes two parts: steel brush grinding and air knife cleaning. The steel brush grinding part includes four steel brushes 6. During the metal compounding process, the rotation direction of the steel brushes 6...

Embodiment 2

[0047] The T3 pure copper strip with a raw material thickness of 0.5mm and the Q345 steel strip with a thickness of 0.5mm are cold-rolled and composited to prepare a copper-steel-copper composite ultra-thin strip. The main steps are as follows:

[0048] (1) Put the coiled copper strip, steel strip and copper strip respectively on three reels in order, and the ends of the three-layer metal strips are wound on the other side reel through the working roll gap of the rolling mill;

[0049] (2) Start the on-line processing device for the surface of the rolling mill, polish the surface of the copper strip and steel strip to be compounded with a steel brush, and start the air knife at the same time to blow and wash the polished metal surface. The surface treatment equipment includes two parts: a steel brush grinding part and an air knife cleaning part. The steel brush grinding part includes four steel brushes 6. During the process of metal compounding, the rotation direction of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com