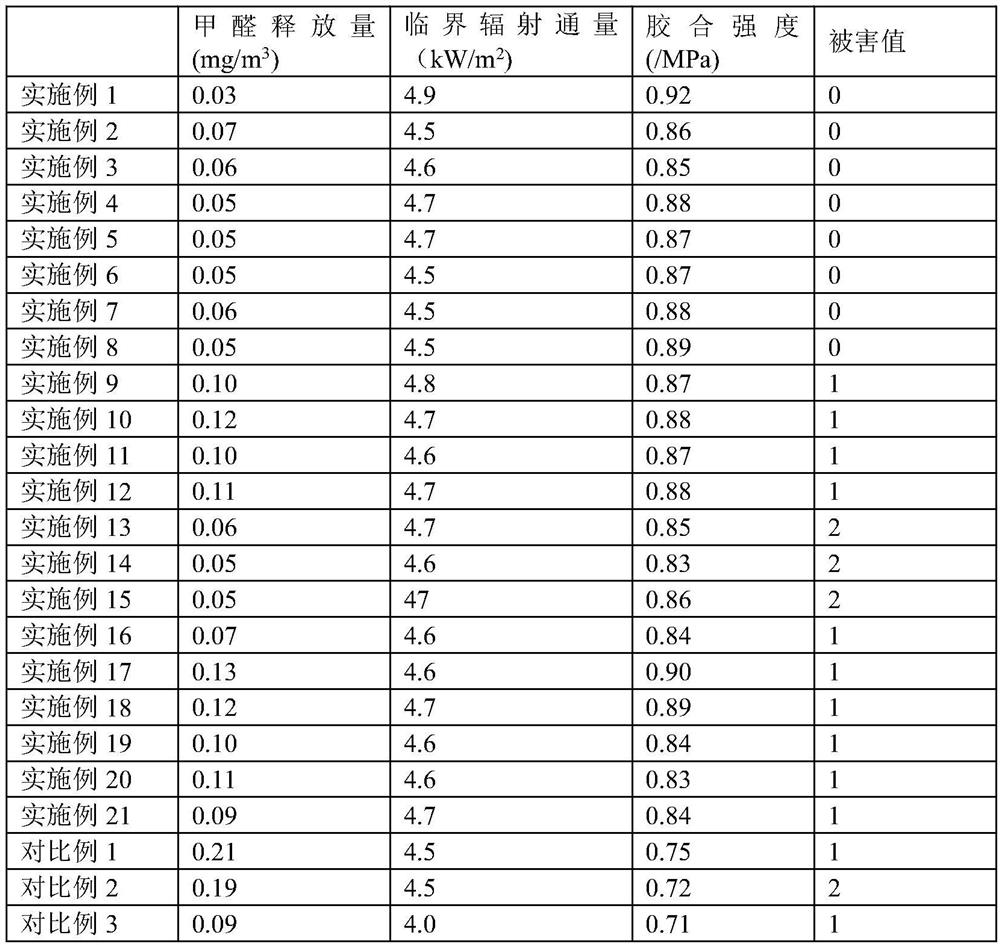

Formaldehyde-free artificial wood board and preparation method thereof

An artificial wood board and veneer technology, which is applied in the jointing of wooden veneers, veneer presses, manufacturing tools, etc., can solve environmental pollution and other problems, and achieve the effects of reducing pollution, strong implementability, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0048]Preparation of hyperbranched waterborne polyurethane: the preparation of hyperbranched waterborne polyurethane in a hyperbranched waterborne polyurethane coating agent with the publication number CN102851987B, adding 17.8g IPDI to the reaction bottle, heating to 65°C, and dissolving 5.4gDMPA in 27mL After DMF, add it into the reaction bottle equipped with IPDI, and keep it at 65°C for 8 hours; then lower the temperature of the reaction system to -10°C, add 4.2g of DEOA dropwise into the reaction system, and keep it at -10°C after the addition is complete. Continue the reaction for 4 hours; then raise the temperature of the reaction system to 90°C, add 0.027g of catalyst, keep at 90°C and continue the reaction for 3h to obtain a colorless transparent liquid, which is distilled under reduced pressure at 70°C for 15 minutes and dried to obtain the desired hyperbranched Water-based polyurethane.

preparation example 2

[0050] Preparation of internal cross-linked water-based polyurethane: add 12 parts of polycarbonate diol and 12 parts of isophorone diisocyanate solution to the reaction kettle, control the ambient temperature at 80°C, and react for 1-2 hours; add 3 parts of acetone, 0.3 Parts of internal crosslinking agent, 6 parts of compound chain extender (wherein the compound chain extender agent includes 2 parts of dimethylol propionic acid, 2 parts of dimethylol butyric acid and 2 parts of trimethylol propane), 1 part Epoxy resin E51 and 1 part of epoxy resin E-44 were mixed and stirred for 2.5 hours; after cooling to 30°C, triethylamine was added to react for about 10 minutes, 5 parts of deionized water were added dropwise, and the temperature of the device was raised to After 50°C, depressurize and distill for 30 minutes to prepare an internally crosslinked water-based polyurethane emulsion.

preparation example 3

[0052] Preparation of composite antibacterial agent: 10 parts of nano-silver solution and 5 parts of viscose fiber were mixed and stirred at 90° C. for 1.5 hours and then dried to obtain solid A; The mass ratio of urea is 2:1) and stirred at a controlled temperature of 80°C for 1 hour, and continued to add solid A, 5 parts of deionized water, and 5 parts of butyl titanate at room temperature and stirred for 1.5 hours to obtain a composite antibacterial agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com