HAYNES282 high-temperature nickel-base alloy pipe welding technology

A nickel-based alloy and welding process technology, which is applied in the welding process field of HAYNES282 high-temperature nickel-based alloy pipes, can solve problems such as easy to be cracked and form thermal cracks, interlayer temperature cannot be controlled, and metal fluidity is poor, so as to ensure the quality of welded joints , improve the welding quality, the effect of beautiful shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A HAYNES 282 high-temperature nickel-based alloy pipe welding process, the HAYNES 282 chemical

[0026] The chemical composition is 57Ni-20Cr-10Co-8.5Mo-Al-Ti, and the specific welding process steps are as follows:

[0027] (1) Material requirements: HAYNES 282, which is a solid solution + aging material, requires steel mills to supply it in solid solution;

[0028] (2) Preparation before welding: prepare the groove, process the groove into a V shape for manual argon tungsten arc welding and hot wire mechanical argon tungsten arc welding, and clean the groove and both sides of the inner and outer walls with acetone to remove For water, oil and dirt, assemble the two pipes that need to be welded;

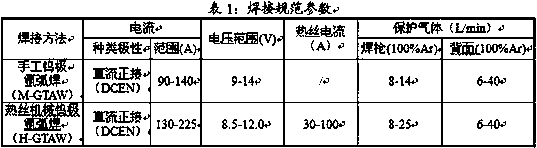

[0029] (3) Welding material preparation: when manual argon tungsten arc welding is used for GTAW welding, 57Ni-20Cr-10Co-8.5Mo-Al-Ti high-temperature nickel-based alloy strip welding wire with a diameter of φ2.4mm is selected, and hot wire mechanical tungsten When welding wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com