Composite material, catalyst using composite material as carrier, and preparation method and applications of catalyst

A composite material and catalyst technology, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of poor conductivity, complicated preparation method, small specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

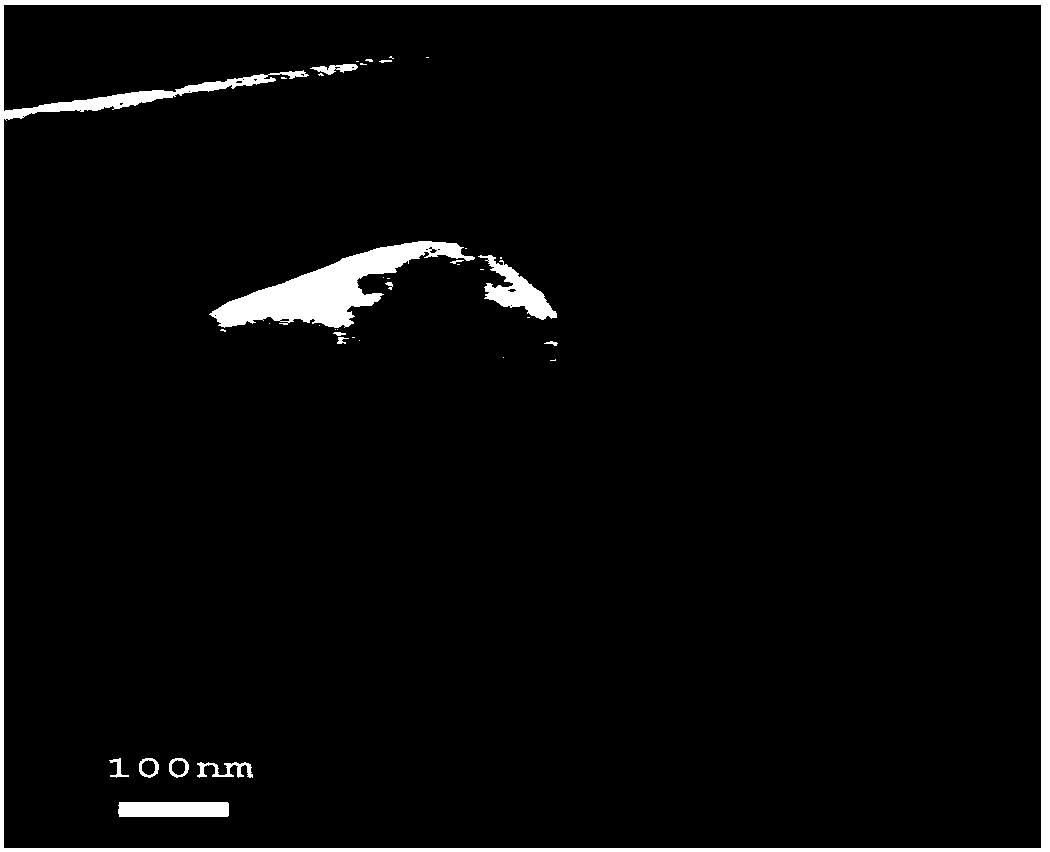

[0028]Weigh 0.2g of carbon powder (XC-72R carbon powder) and ultrasonically disperse it in 8g of ethanol, then add it to the ethanol solution of polyvinylpyrrolidone (the content of polyvinylpyrrolidone is 7.4wt.%), stir while ultrasonically, and then add 2g of acetic acid, then add 1g of butyl titanate, stir for 2 hours to get a black spinning solution, put it into a syringe after static defoaming, and then fix it on the electrospinning workbench, the distance between the workbench and the roller or stainless steel plate The feeding speed of the spinning solution is 0.02mm / min, the working voltage of 20kV is applied, and the aluminum foil is fixed on the roller to collect the fibers. The rotation speed of the roller is 120rpm, or 100-300rpm. Finally, the fibers were removed from the aluminum foil paper, put into a muffle furnace and calcined at 400°C for 4 hours to obtain titanium oxide-carbon (TiO 2 -C) Nanofibers. figure 1 For the prepared TiO 2 -SEM image of C.

[0029]...

Embodiment 2

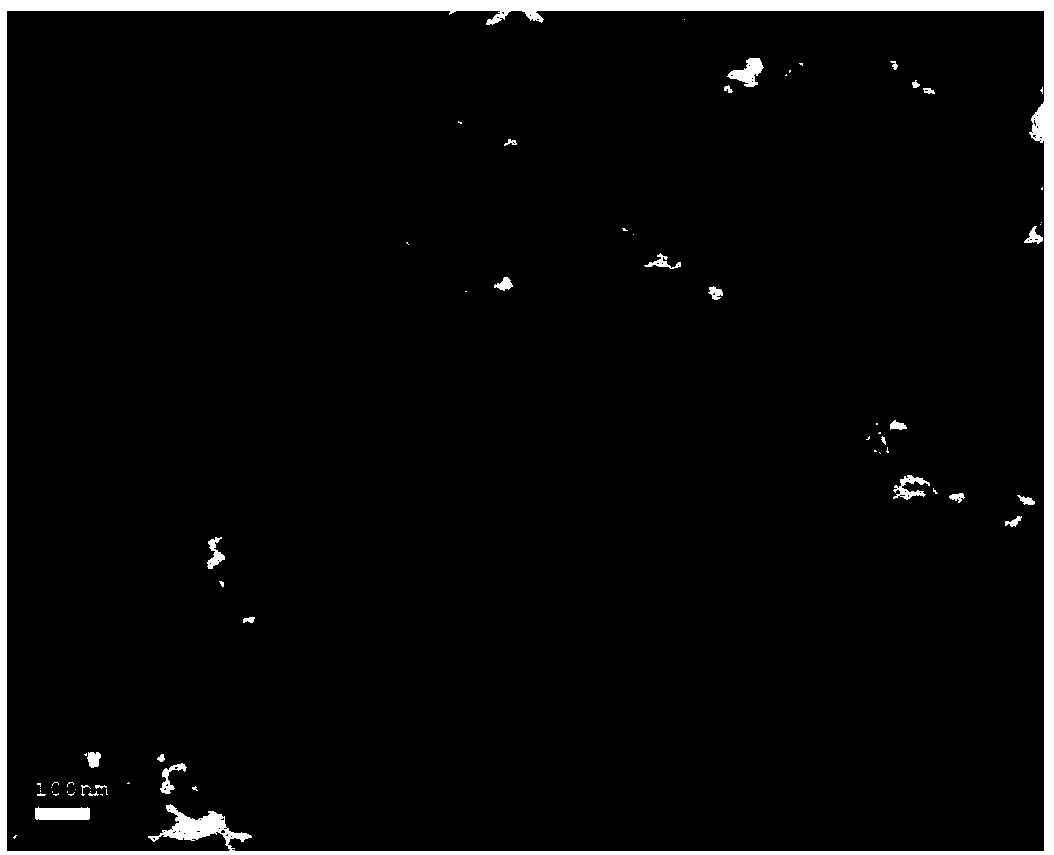

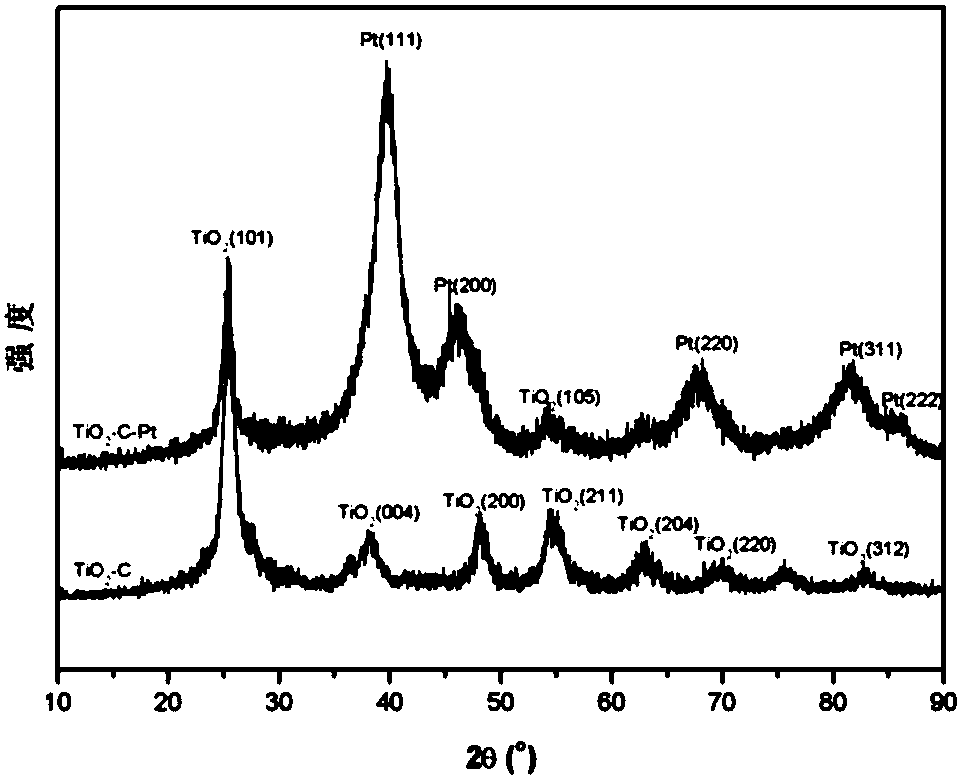

[0031] One-step preparation of TiO by electrospinning 2 -C-Pt electrocatalyst: Weigh 0.2g of carbon powder (XC-72R carbon powder) and ultrasonically disperse it in 10g of ethanol, then add it to the ethanol solution of polyvinylpyrrolidone (the content of polyvinylpyrrolidone is 10wt.%). Stir while ultrasonic, then add 2 g of acetic acid, then add 1 g of butyl titanate, stir for 2 hours, then add 0.15 g of chloroplatinic acid ethanol solution (the concentration of chloroplatinic acid solution is 0.15 g / mL) dropwise to the above black solution In the end, a spinning solution is obtained. Subsequently, the spinning solution was left to defoam and then moved into a syringe for electrospinning, as in Example 1, and finally the obtained fibers were put into a muffle furnace for 350°C for 2 hours, and the Ti salt and the Pt salt were decomposed while the polymer was decomposed. decomposed into TiO 2 and Pt, and finally get TiO 2 -C-Pt electrocatalysts. Figure 4 The XRF characte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com