Gold-gallium-cobalt alloy composite bonding wire with gold coating layer and manufacturing method thereof

A technology of a gold cladding layer and a manufacturing method, which is applied in the field of gold-gallium-cobalt alloy composite bonding wire and its manufacturing, can solve the problems of low tensile strength of gold bonding wire, unfavorable improvement of competitiveness of enterprises, and difficult control of elongation, etc. Achieve the effect of improving anti-oxidation ability and anti-vulcanization ability, improving the adaptability of the machine, and increasing the window of the wire-bonding operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

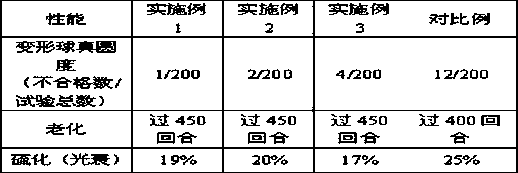

Examples

Embodiment 1

[0035] The gold-gallium-cobalt alloy composite bonding wire with a gold cladding layer of the present embodiment includes a core wire and a gold cladding layer coated outside the core wire; the core wire contains Ga 5%, Co 0.8% by weight, The balance is gold; the thickness of the gold cladding layer is 100nm.

[0036] In this embodiment, the manufacturing method of the gold-gallium-cobalt alloy composite bonding wire having a gold coating layer comprises the following steps:

[0037] (1) Melting and casting: Ga and Co are added to the gold raw material in proportion, and after vacuum melting and directional continuous casting process, a core wire with a diameter of 8 mm is obtained;

[0038] (2) Wire drawing: drawing the core wire obtained in step (1) to obtain a bonding wire core wire with a diameter of 200um;

[0039] In this step (2), during the wire drawing process, the wire is subjected to intermediate annealing several times, and N 2 As the annealing atmosphere, the ef...

Embodiment 2

[0053] The gold-gallium-cobalt alloy composite bonding wire with a gold cladding layer of the present embodiment comprises a core wire and a gold cladding layer coated on the outside of the core wire; the core wire contains 8% by weight of Ga, 0.05% of Co, The balance is gold; the thickness of the gold cladding layer is 180nm.

[0054] In this embodiment, the manufacturing method of the gold-gallium-cobalt alloy composite bonding wire having a gold coating layer comprises the following steps:

[0055] (1) Melting and casting: Ga and Co are added to the gold raw material in proportion, and after vacuum melting and directional continuous casting process, a core wire with a diameter of 7 mm is obtained;

[0056] (2) Wire drawing: drawing the core wire obtained in step (1) to obtain a bonding wire core wire with a diameter of 50um;

[0057] In this step (2), during the wire drawing process, the wire is subjected to intermediate annealing several times, and N 2 As the annealing a...

Embodiment 3

[0071] The gold-gallium-cobalt alloy composite bonding wire with a gold cladding layer in this embodiment includes a core wire and a gold cladding layer coated outside the core wire; the core wire contains 3.5% by weight of Ga, 1.5% of Co, The balance is gold; the thickness of the gold cladding layer is 20nm.

[0072] In this embodiment, the manufacturing method of the gold-gallium-cobalt alloy composite bonding wire having a gold coating layer comprises the following steps:

[0073] (1) Melting and casting: Ga and Co are added to the gold raw material in proportion, and after vacuum melting and directional continuous casting process, a core wire with a diameter of 8 mm is obtained;

[0074] (2) Wire drawing: drawing the core wire obtained in step (1) to obtain a bonding wire core wire with a diameter of 200um;

[0075] In this step (2), during the wire drawing process, the wire is subjected to intermediate annealing several times, and N 2 As the annealing atmosphere, the ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com