Preparation method of hydroxyapatite biological ceramics with strontium cooperated with ordered micrometer structure for osteogenesis

A hydroxyapatite and bioceramic technology, applied in the field of biomedical materials, can solve the problems of complex mask preparation process, time-consuming, thermal damage of bioceramic materials, etc., and achieves novel preparation method, improved osteogenic activity, and good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

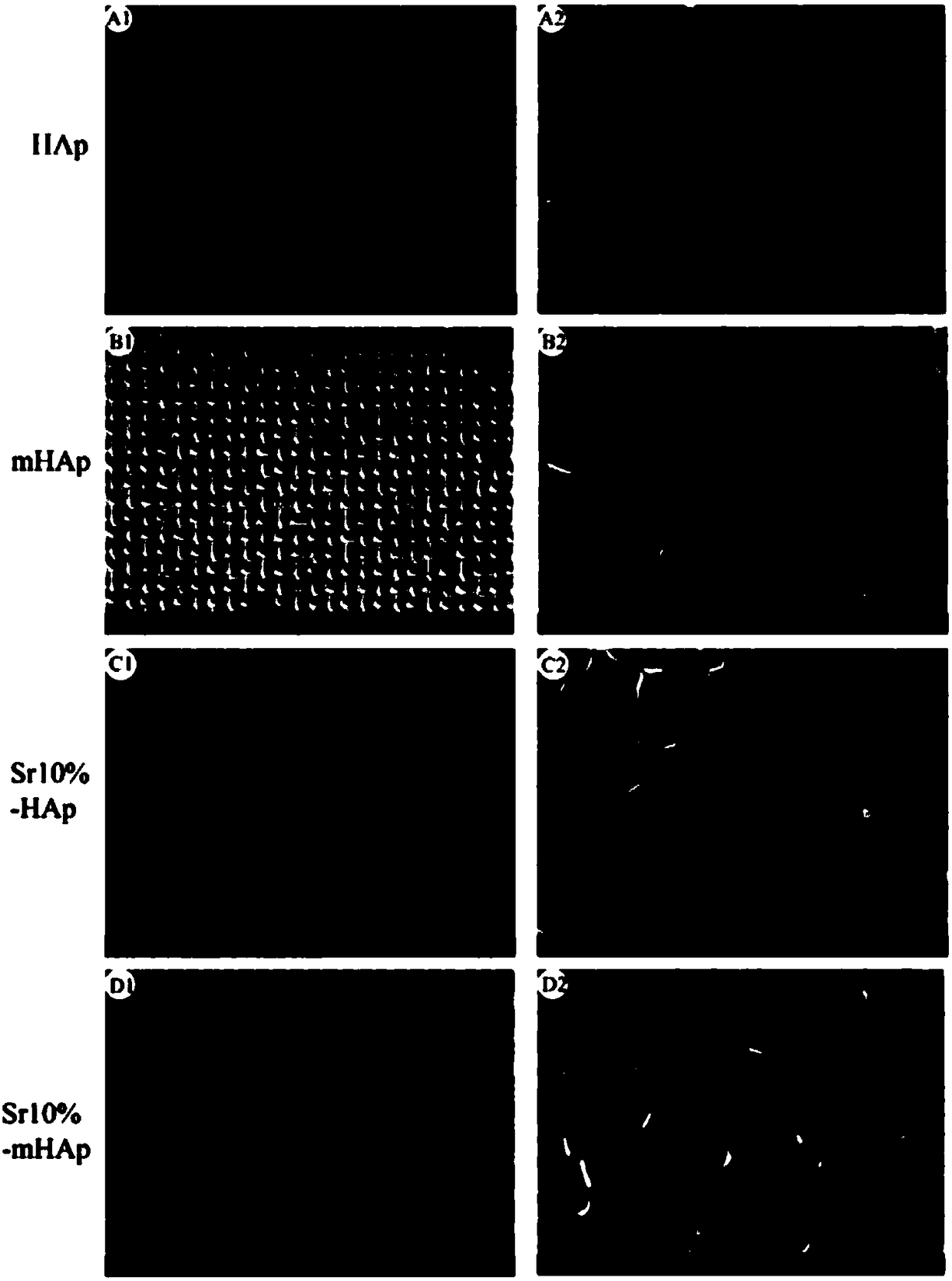

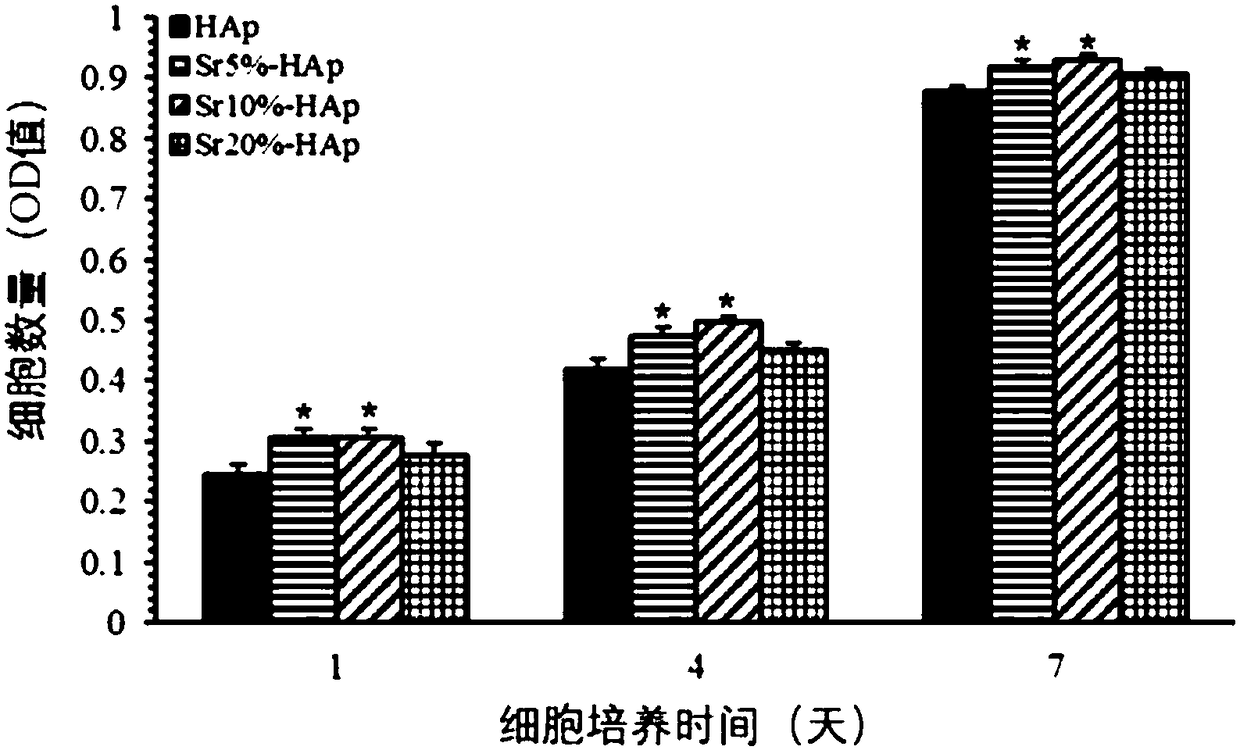

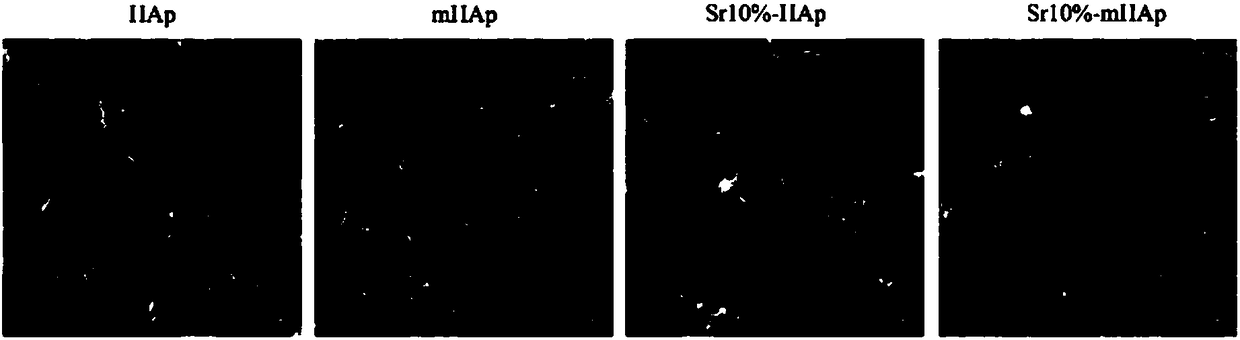

[0033] Mix 10% strontium-doped hydroxyapatite bioceramic powder and binder (polyvinyl alcohol with a mass percentage of 8%) evenly, and place the stainless steel mold with an organic plastic mesh screen with a pore size of 38 μm at the bottom at 100kg / cm 2 After dry pressing under pressure, calcining at 1050°C for 5 hours, and cooling in the furnace, a 10% strontium-doped hydroxyapatite bioceramic (Sr10%-mHAp) with an ordered microstructure on the surface can be obtained.

Embodiment 2

[0035] After mixing 5% strontium-doped hydroxyapatite bioceramic powder and binder (8% polyvinyl alcohol by mass percentage), place the stainless steel mold with an organic plastic mesh screen with a pore size of 25 μm at the bottom at 200kg / cm 2 After dry pressing under pressure; then calcining at 1000° C. for 3 hours, and cooling down in the furnace, a 5% strontium-doped hydroxyapatite bioceramic (Sr5%-mHAp) with an ordered microstructure on the surface can be obtained.

Embodiment 3

[0037] After mixing 20% strontium-doped hydroxyapatite bioceramic powder and binder (8% polyvinyl alcohol by mass percentage), place the stainless steel mold with an organic plastic mesh screen with a pore size of 75 μm at the bottom at 150kg / cm 2 Dry press molding under pressure; then calcined at 1200°C for 2 hours, and after cooling down in the furnace, a hydroxyapatite bioceramic (Sr20%-mHAp) with 20% strontium-doped surface ordered microstructure can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com